Overview

Production equipment, products and services are analyzed using cloud computing and big data, and optimization solutions are implemented through device interconnection. As a result, the Internet of Things and Industry 4.0 share many common aspects.

Impact of the Internet of Things on the Sensor Industry

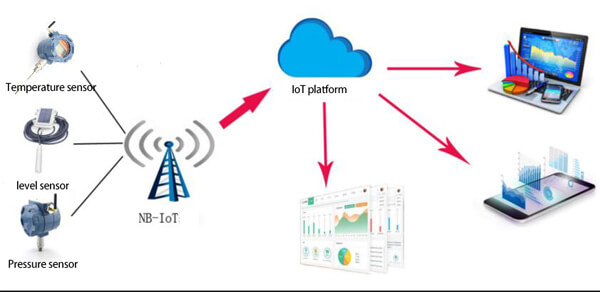

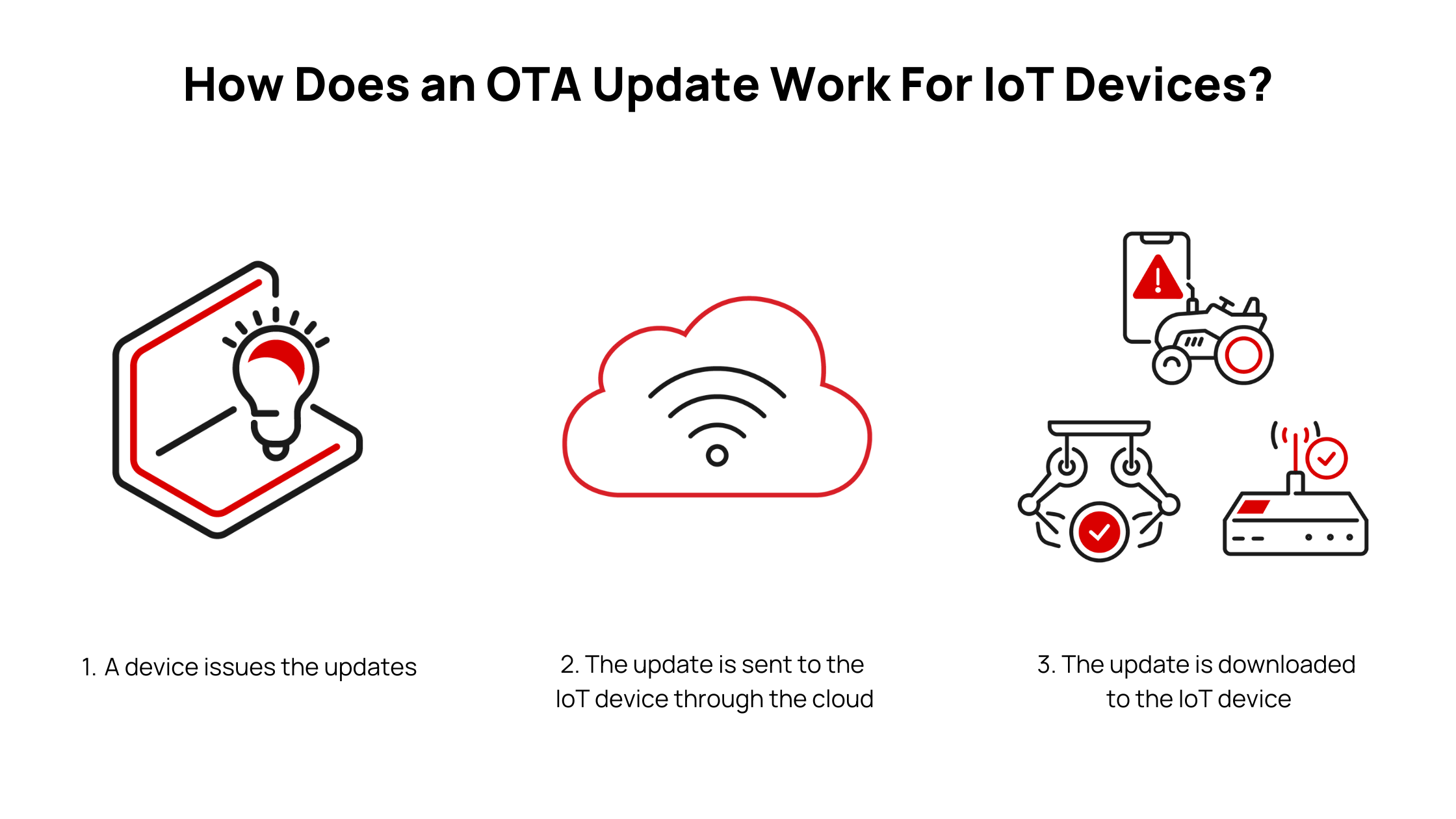

On one hand, the Internet of Things creates opportunities for sensor manufacturers. On the other hand, it imposes new requirements on sensors, particularly for higher sensitivity, stability, and robustness. With the spread of the industrial internet, sensors are becoming ubiquitous. Large-scale deployment drives demand for lightweight, low-power, and low-cost sensors, while also requiring greater network connectivity, integration, and intelligence.

In addition, IoT sensor applications span a wider range of fields, increasing the required quantity of sensors and the need for industrial-scale production. Like integrated circuit chips, sensors are key components of high-technology systems.

Sensor Applications in the IoT

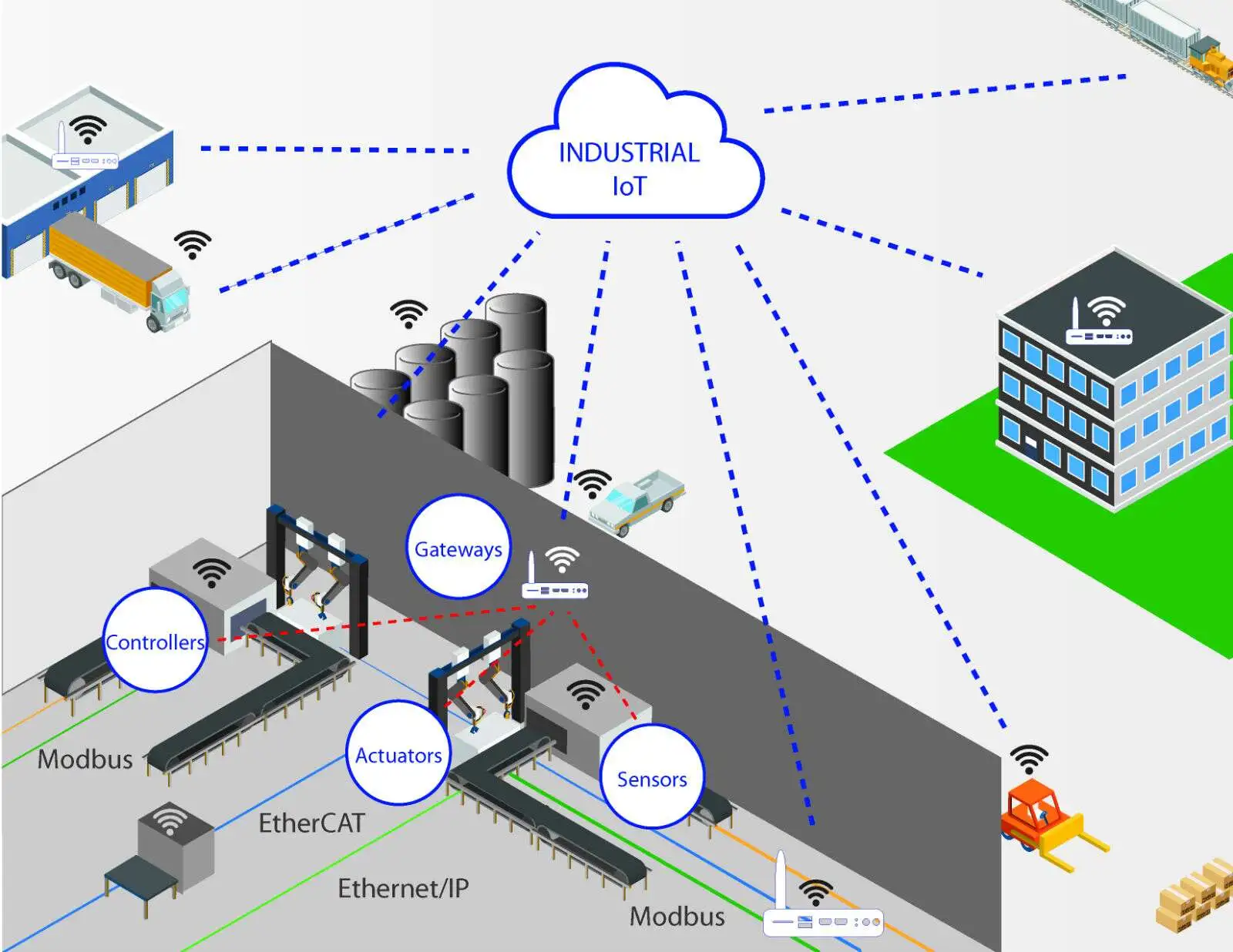

Factory automation, building automation, smart grids, and public transportation are important IoT application areas. Increasingly, technicians and maintenance personnel will use tablet computers to collect and process information sent by sensors integrated into industrial machinery.

1. Industrial Environmental Monitoring

Industrial environmental monitoring covers many aspects of the ecosystem, including air, water, electromagnetic radiation, and radioactivity. There are also specialized monitoring scenarios, such as deserts, mountains, and radioactive sources. These environments place high demands on sensor flexibility, reliability, and safety.

2. Smart Grid

Global concerns about energy, the environment, and climate change have made the development and use of clean energy a priority in many countries. The smart grid is a key IoT application and an inevitable direction for power system development. Smart grids rely on advanced sensing and measurement technologies, communication technologies, control methods, and decision support systems to ensure the safety, reliability, and economic efficiency of the power supply.

3. Digital Oilfield

Digital oilfields, featuring automated production and intelligent management, are an emerging trend. In the digitalization of oilfields, wireless sensor network products can monitor well environments and wellhead equipment in real time, transmitting equipment status and environmental parameters to a control center, issuing alerts, and coordinating dispatch when necessary. As wireless sensor network products are more widely adopted, the number of digital oilfields will grow and market demand for these products is expected to increase rapidly.

4. Smart Industry

Applying sensor network technology to industrial monitoring helps optimize production processes and improves capabilities for detection, real-time parameter acquisition, equipment monitoring, and material consumption monitoring. This enables intelligent monitoring, control, diagnosis, decision-making, and maintenance across production processes.

ALLPCB

ALLPCB