1. Background and requirements

As the smart toy market advances, interactive children's devices are evolving from simple light-and-sound feedback to more conversational behavior. The WT3000A-M6 module offers millisecond-level response latency, multimodal interaction capabilities, and child-focused safety features, making it suitable for smart toy applications. This document provides a PCB implementation path for typical smart toy hardware, such as educational robots, story players, and interactive dolls.

2. System architecture

2.1 Overall framework

Adopt a dual-core heterogeneous architecture:

- Main controller: STM32 H750 as the system MCU, communicating with WT3000A-M6 via SPI interface

- Voice processing unit: WT3000A-M6 performs wake word detection, noise reduction, and local command recognition

- Expansion interfaces: Reserved GPIOs to control motors/lights, PWM interface to drive expressive displays

2.2 Signal flow

Microphone array -> module audio input -> voice processing -> local commands -> main controller executes actions; cloud interaction -> WebSocket upload -> TTS playback

3. Key circuit design

3.1 Audio capture system

Design approach:

- Use a 4-microphone ring array, 15 mm spacing, to achieve 360° pickup

- Front-end amplification: TI OPA1678, adjustable gain range 40–60 dB

- Configure a second-order Butterworth filter with a 16 kHz cutoff frequency

Feedback sampling circuit:

- Install a 1% precision sampling resistor at the speaker output

- Use AD A4077 to construct a feedback loop to eliminate howling

Layout notes:

- Microphone trace length differences < 5 mm, matching error ±0.1 mm for equal length

- Analog ground and digital ground connected at a single point via a 0 Ω resistor

3.2 Wireless communication

Bluetooth/WiFi integrated design:

- Shared PCB inverted-F antenna, size 20 x 5 mm

- RF front end: use SKY66421 front-end module

- Configure a pi-type matching network and tune with a Smith chart to 2.4 GHz

- Isolation: keep Bluetooth and WiFi modules > 15 mm apart

- Use metal shielding cans to separate RF areas

3.3 Power management

Three-tier power architecture:

- Main power: 3.7 V Li-ion input, TPS61088 boost to 5 V

- Module power: 3.3 V LDO: TPS7A4701 (noise 3 uVrms)

- Dynamic voltage regulation: switch between 2.8 V and 3.6 V according to operating mode

- Peripheral power:

- Motor drive: SY8089 DC-DC with 2 A output capability

- LED strips: PT4115 constant-current driver IC

- Low-power design:

- Standby current < 50 uA (voice wake mode)

- Use TPS22916 load switches for modular power control

4. PCB layout optimization

4.1 Stackup

Use a 6-layer board:

- Layer 1: signal layer (key analog traces)

- Layer 2: ground plane

- Layer 3: power plane

- Layer 4: digital signal layer

- Layer 5: RF dedicated layer

- Layer 6: bottom layer (high-current paths)

4.2 Key area placement

Voice processing area:

- Place WT3000A-M6 near the center, within 20 mm of the microphones

- Reserve a 10 x 10 mm thermal copper area

RF area:

- Maintain a 3 mm keep-out around the antenna

- Impedance control: 50 Ω ± 10%

Motor drive area:

- Use 2 oz copper for high current paths

- Provide TVS array protection (ESD 5Z3.3T1G)

4.3 Signal integrity

- Voice I2S bus: length matching error < 5 mil, spacing following 3W rule

- Digital signal lines: add 33 Ω series resistors for termination

- Clock signals: guard with ground, length < 50 mm

5. Child safety design

5.1 Hardware safety mechanisms

- Over-temperature protection: NTC thermistor + MAX6613 monitoring chip

- Tamper detection: use FPC flexible connectors for removable parts

- Electromagnetic safety: comply with EN 62115 toy safety standards

5.2 Acoustic safety control

- Limit output sound pressure level to below 75 dB

- Use an automatic level control (ALC) circuit:

- Use TS472 headphone amplifier

- Dynamic range compression ratio 4:1

6. Development support

6.1 Reference design kit

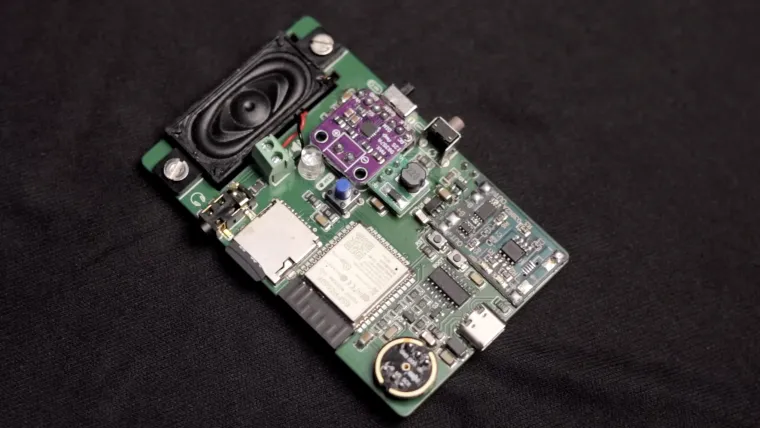

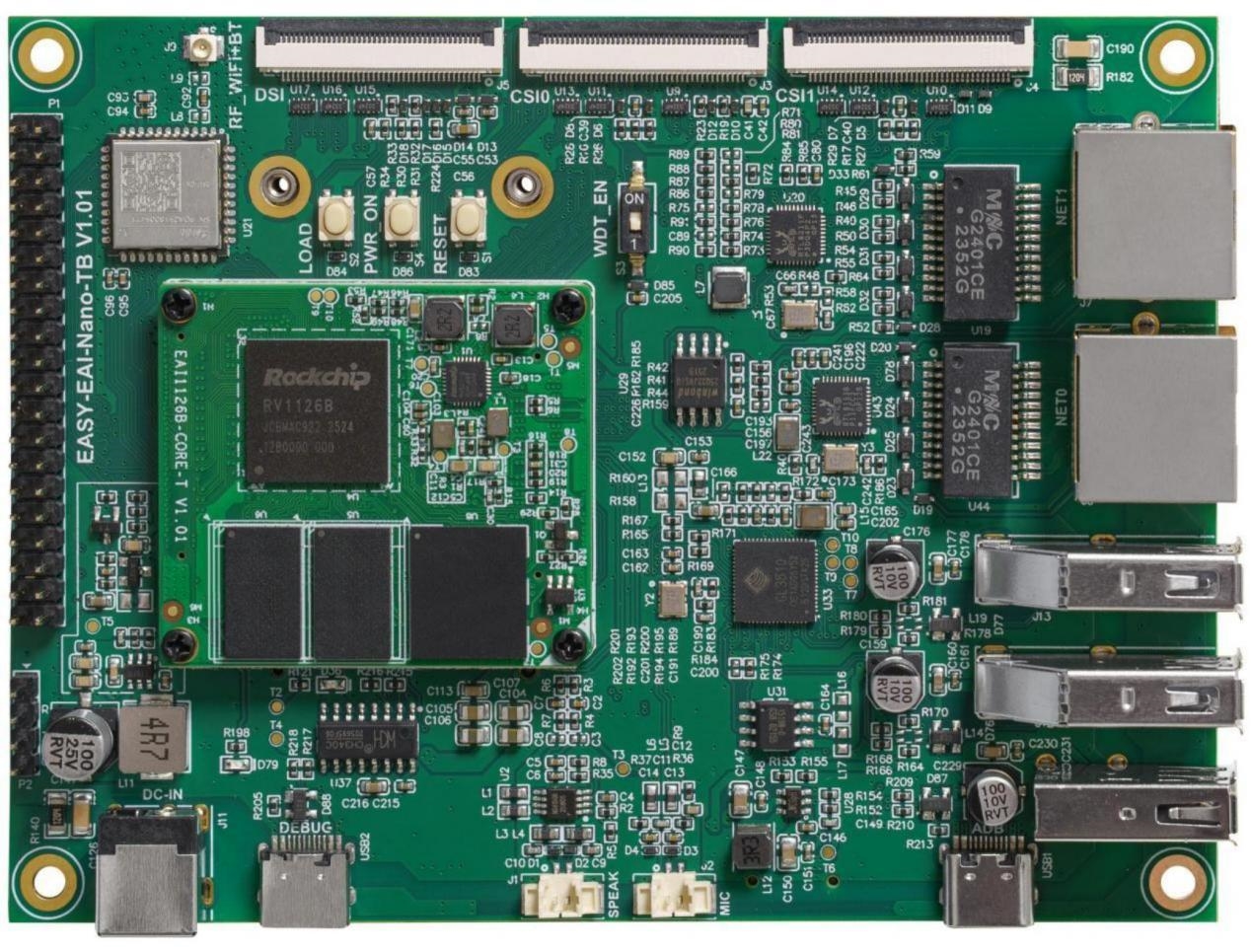

Provide a core board (50 x 30 mm) plus expansion board architecture including:

- Typical toy control interfaces (servos/PWM LED/touch sensing)

- Offline voice training tools (supports Mandarin child voice optimization)

6.2 Rapid production recommendations

- Stencil design suggestions: module pad aperture ratio 1:0.9

- Use Type 5 solder powder (20–38 μm)

- Test fixtures: acoustic test chamber (compliant with IEC 60268-21)

- RF test system automatic calibration procedures

7. Typical application example

Educational robot implementation:

Functional features:

- Wake word: "Xiao Zhi Teacher"

- Local recognition of 100+ teaching commands (for example, "spell check")

- Cloud connection to ChatGPT for Q&A interactions

Performance targets:

- Wake response time < 200 ms

- Continuous operation: 8 hours battery life

- Operating temperature range: -20°C to 60°C

8. Cost optimization strategies

BOM optimization:

- Use 0402 package components to reduce area by about 30%

- Select HSCODE-8L no-clean solder paste to lower processing cost

Production optimization:

- Support panelization (2 x 2 panel)

- Automated ICT solutions with > 95% test coverage

ALLPCB

ALLPCB