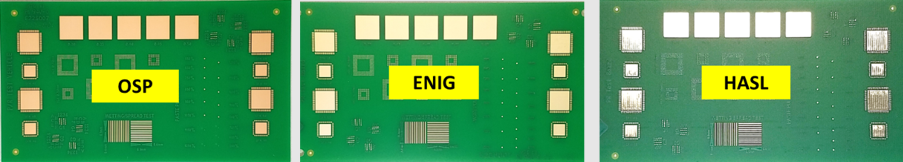

When it comes to choosing a surface finish for your printed circuit board (PCB), the decision can significantly impact the performance, cost, and longevity of your electronics project. Among the many options available, Organic Solderability Preservative (OSP) stands out as a popular choice, especially for budget-conscious DIY enthusiasts and small-scale projects. But how does OSP compare to other finishes like Hot Air Solder Leveling (HASL) and Electroless Nickel Immersion Gold (ENIG)? In this detailed guide, we’ll break down the differences through an in-depth PCB finish comparison, focusing on OSP vs HASL and OSP vs ENIG, to help you make the best surface finish choice for your DIY electronics or professional PCB project.

Quick Answer: OSP is often the best choice for cost-effective, environmentally friendly projects with simpler soldering needs, while HASL offers durability for through-hole components, and ENIG provides superior corrosion resistance and flatness for fine-pitch components. Your choice depends on your project’s specific requirements, budget, and assembly process.

Now, let’s dive deeper into each surface finish, their pros and cons, and how they fit into different electronics projects. Whether you’re a hobbyist or an engineer, this PCB project guide will provide actionable insights to help you decide.

What Are PCB Surface Finishes and Why Do They Matter?

A PCB surface finish is a protective coating applied to the exposed copper traces on a circuit board. Its primary purposes are to prevent oxidation, ensure good solderability during assembly, and extend the board’s shelf life. Without a surface finish, copper can quickly corrode when exposed to air, leading to poor connections and potential failure of your electronics project.

The right surface finish choice can affect several factors, including:

- Solderability: How well components can be soldered to the board.

- Durability: Resistance to wear, corrosion, and environmental factors.

- Cost: Some finishes are more expensive due to materials or complex application processes.

- Compatibility: Certain finishes work better with specific component types or assembly methods.

With options like OSP, HASL, and ENIG, understanding their differences is key to optimizing your PCB design. Let’s start by exploring OSP and then compare it to other common finishes.

What is OSP (Organic Solderability Preservative)?

OSP is a water-based, organic coating applied to the copper surfaces of a PCB to protect against oxidation. It forms a thin, transparent layer that preserves solderability by acting as a barrier between the copper and the environment. OSP is often favored for its simplicity and environmental friendliness since it doesn’t involve heavy metals or hazardous chemicals.

Advantages of OSP

- Cost-Effective: OSP is one of the least expensive surface finishes, making it ideal for DIY electronics projects on a tight budget.

- Environmentally Friendly: Unlike some finishes that use lead or other harmful substances, OSP is RoHS-compliant and eco-friendly.

- Flat Surface: OSP provides a flat surface, which is beneficial for surface-mount technology (SMT) components, ensuring even solder distribution.

- Simple Process: The application of OSP is straightforward, often reducing manufacturing time.

Disadvantages of OSP

- Limited Shelf Life: OSP typically has a shelf life of 6-12 months under proper storage conditions (temperature below 25°C and humidity below 60%). After this period, solderability can degrade.

- Fragile Coating: The organic layer is thin and can be easily damaged during handling or multiple soldering cycles, exposing the copper underneath.

- Not Ideal for Multiple Reflows: OSP may not withstand repeated soldering processes, making it less suitable for complex assemblies requiring multiple reflow cycles.

OSP is a great surface finish choice for simpler projects or prototypes where cost and environmental impact are priorities. However, for more demanding applications, other finishes might be better suited.

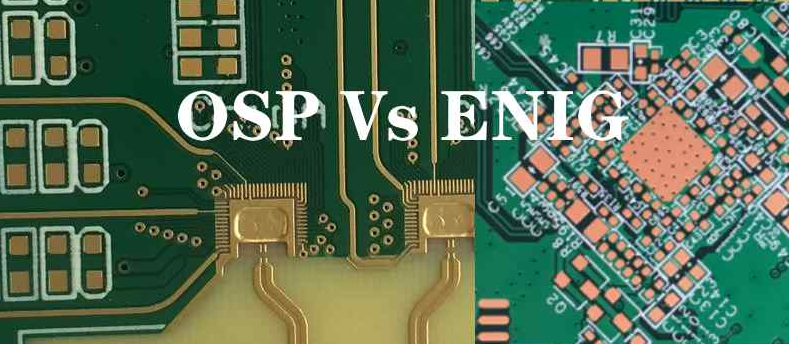

OSP vs HASL: A Detailed Comparison

Hot Air Solder Leveling (HASL) is one of the oldest and most widely used surface finishes in the industry. It involves dipping the PCB into molten solder and then using hot air to level the coating, leaving a layer of tin-lead or lead-free solder on the copper surfaces. Let’s compare OSP vs HASL across key factors.

Cost

OSP generally has a lower cost than HASL. While HASL is still relatively affordable, the process of applying molten solder and leveling it with hot air adds to manufacturing expenses. For DIY electronics enthusiasts working on low-budget projects, OSP might be the better choice.

Solderability

HASL offers excellent solderability because the solder layer already on the board ensures strong bonding during assembly. OSP, while effective for a single soldering cycle, may not perform as well if the board is stored for too long or undergoes multiple reflows. HASL is often preferred for through-hole components due to its robust solder joint formation.

Surface Flatness

OSP provides a flatter surface compared to HASL, which can have uneven solder distribution due to the hot air leveling process. This unevenness (often varying by 1-5 micrometers) can cause issues with fine-pitch SMT components. If your project involves tiny components with tight spacing, OSP might be more suitable.

Durability and Shelf Life

HASL is more durable than OSP and has a longer shelf life, often exceeding 12 months even in less-than-ideal storage conditions. OSP’s organic coating, as mentioned, is prone to degradation over time or with rough handling.

Environmental Impact

OSP wins in terms of environmental friendliness. Traditional HASL uses tin-lead solder, which is not RoHS-compliant, though lead-free HASL options are available. Still, the energy-intensive hot air leveling process makes HASL less eco-friendly than OSP.

Best Use Cases: Choose OSP over HASL for cost-sensitive SMT projects with simpler assembly needs. Opt for HASL if your project involves through-hole components or requires a longer shelf life.

OSP vs ENIG: A Detailed Comparison

Electroless Nickel Immersion Gold (ENIG) is a premium surface finish that involves depositing a layer of nickel over the copper, followed by a thin layer of gold. This combination offers excellent corrosion resistance and solderability. Let’s break down OSP vs ENIG.

Cost

ENIG is significantly more expensive than OSP due to the use of gold and the complex chemical deposition process. For hobbyists or small-scale DIY electronics projects, OSP is the more budget-friendly option. ENIG is typically reserved for high-reliability applications where cost is less of a concern.

Solderability

ENIG provides superior solderability compared to OSP. The gold layer ensures excellent wetting during soldering, and the nickel underlayer acts as a barrier to prevent copper diffusion. ENIG can handle multiple reflow cycles without degrading, unlike OSP, which may struggle after the first soldering attempt if not stored properly.

Surface Flatness

Both OSP and ENIG offer flat surfaces, making them suitable for fine-pitch SMT components. ENIG, however, provides a more consistent finish with thickness control within 0.05-0.1 micrometers for the gold layer, ensuring precision for high-density designs.

Durability and Shelf Life

ENIG far outperforms OSP in terms of durability and shelf life. The nickel-gold combination resists corrosion and oxidation even after years of storage (often exceeding 24 months). OSP’s organic coating, by contrast, is more vulnerable to environmental factors and physical damage.

Environmental Impact

OSP is more environmentally friendly than ENIG. The chemical processes used in ENIG involve hazardous substances, and while the gold layer is thin (typically 0.05-0.2 micrometers), it still adds to the environmental footprint compared to OSP’s organic, water-based solution.

Best Use Cases: Opt for OSP if you’re working on a low-cost project with basic requirements. Choose ENIG for high-reliability projects, such as medical or aerospace electronics, where long-term performance and corrosion resistance are critical.

Key Factors to Consider for Surface Finish Choice

Selecting the right surface finish for your electronics project involves evaluating several factors. Here’s a PCB project guide to help you decide:

1. Project Budget

If cost is a major concern, OSP is often the best choice due to its low price point. HASL is also affordable, while ENIG is better suited for projects with larger budgets.

2. Component Types

For projects with fine-pitch SMT components, OSP or ENIG are preferable due to their flat surfaces. HASL works well for through-hole components where surface unevenness is less of an issue.

3. Assembly Process

If your project requires multiple reflow cycles or complex assembly, ENIG’s durability makes it the top choice. OSP might not hold up under repeated soldering, and HASL can vary depending on the lead-free or leaded option used.

4. Storage and Shelf Life

For projects that may sit in storage for extended periods before assembly, ENIG or HASL are better options than OSP due to their longer shelf life.

5. Environmental Considerations

If environmental impact is a priority, OSP stands out as the most eco-friendly option among the three finishes discussed.

Practical Tips for DIY Electronics Projects

For hobbyists and DIY enthusiasts, surface finish choice can make or break a project. Here are some actionable tips to ensure success:

- Store OSP Boards Properly: If you choose OSP, keep boards in a cool, dry place (below 25°C and 60% humidity) to maximize shelf life. Use vacuum-sealed packaging if possible.

- Test Solderability: Before full assembly, test a small area of your PCB to ensure the surface finish supports good soldering, especially with OSP after prolonged storage.

- Handle with Care: OSP coatings are delicate. Wear gloves and avoid touching the board surface to prevent contamination or damage.

- Plan Assembly Timeline: If using OSP, plan your assembly within 6-12 months to avoid solderability issues. For longer timelines, consider HASL or ENIG.

- Match Finish to Soldering Method: If you’re hand-soldering through-hole components, HASL might be easier to work with. For automated SMT assembly, OSP or ENIG could be better due to flatness.

Conclusion: Making the Right Surface Finish Choice

Choosing between OSP, HASL, and ENIG for your electronics project depends on a balance of cost, performance, and specific application needs. OSP shines as a cost-effective, eco-friendly option for simpler DIY electronics projects with SMT components. HASL offers durability and excellent solderability for through-hole designs at a reasonable price. ENIG, while more expensive, provides unmatched corrosion resistance and reliability for high-end applications.

By understanding the strengths and limitations of each finish through this PCB finish comparison, you can confidently select the best surface finish choice for your next project. Whether you’re a hobbyist or a professional engineer, aligning your decision with your project’s requirements ensures optimal results and long-term success.

ALLPCB

ALLPCB