In the world of electronics manufacturing, protecting printed circuit boards (PCBs) from environmental hazards like moisture, dust, and chemicals is critical. One of the most effective ways to ensure this protection is through conformal coating. However, the success of this protective layer heavily depends on the curing process. If you're searching for the best ways to optimize conformal coating curing methods, including UV curing, thermal curing, moisture curing, and curing time, you've come to the right place. This guide will dive deep into these techniques, offering actionable insights to achieve a flawless finish for your PCBs.

At ALLPCB, we understand the importance of a reliable curing process to ensure the longevity and performance of electronic assemblies. In this comprehensive blog, we'll explore the various conformal coating curing methods, break down their advantages and challenges, and provide practical tips to help you perfect your process.

What is Conformal Coating and Why Does Curing Matter?

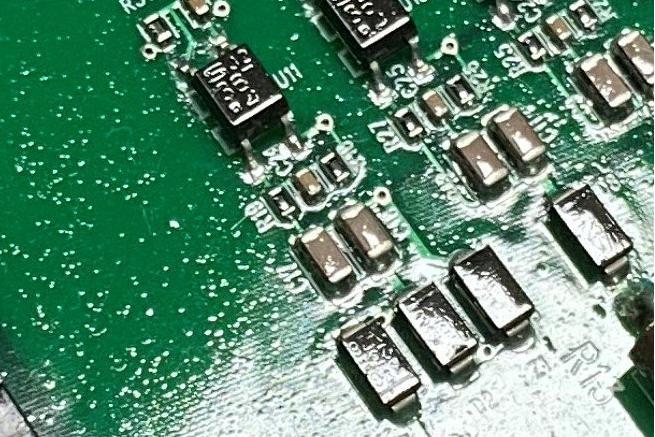

Conformal coating is a thin, protective polymeric film applied to PCBs to shield them from environmental stressors such as humidity, temperature extremes, and corrosive substances. This coating "conforms" to the irregular surface of the board, creating a barrier that enhances dielectric resistance and operational reliability.

However, applying the coating is only half the battle. The curing process—where the coating hardens and bonds to the PCB surface—is just as crucial. A poorly cured coating can lead to defects like cracking, incomplete adhesion, or insufficient protection, leaving your electronics vulnerable. Optimizing the curing process ensures the coating performs as intended, providing long-lasting protection.

Understanding Conformal Coating Curing Methods

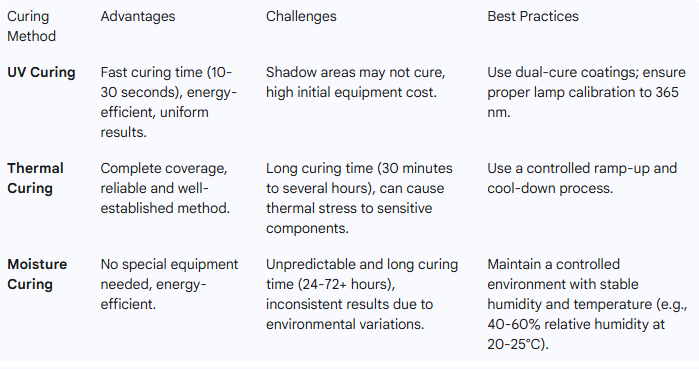

There are several curing methods available for conformal coatings, each with its own set of benefits and considerations. Below, we’ll explore the most common techniques—UV curing, thermal curing, and moisture curing—along with key factors like curing time that impact the final result.

1. Conformal Coating UV Curing: Speed and Precision

UV curing is a popular method for conformal coatings due to its rapid processing time and high precision. This technique uses ultraviolet (UV) light to initiate a chemical reaction in the coating material, typically an acrylic or urethane-based compound, causing it to harden almost instantly.

Advantages of UV Curing:

- Fast Curing Time: UV curing can solidify a coating in seconds, often between 10 to 30 seconds under a UV lamp with an intensity of 100-300 mW/cm2, making it ideal for high-volume production.

- Energy Efficiency: Unlike thermal methods, UV curing doesn’t require high temperatures, reducing energy costs.

- Uniform Results: The process ensures consistent curing across the surface, minimizing defects like uneven thickness.

Challenges:

- Shadow Areas: UV light cannot penetrate shadowed or hidden areas under components, potentially leaving parts of the PCB uncured.

- Equipment Cost: UV curing systems and lamps can be expensive to set up initially.

Best Practices for UV Curing: Use a dual-cure coating that combines UV curing with a secondary mechanism (like moisture curing) to address shadow areas. Ensure the UV lamp is calibrated to the correct wavelength, typically 365 nm for most coatings, to achieve optimal results.

2. Conformal Coating Thermal Curing: Reliable and Thorough

Thermal curing involves exposing the coated PCB to elevated temperatures in an oven or heated chamber to harden the coating. This method is commonly used for silicone, epoxy, and polyurethane coatings.

Advantages of Thermal Curing:

- Complete Coverage: Heat penetrates all areas of the PCB, ensuring uniform curing even in shadowed regions.

- Proven Reliability: Thermal curing is a well-established method, often used in industries requiring high durability, such as automotive and aerospace.

Challenges:

- Longer Curing Time: Thermal curing can take anywhere from 30 minutes to several hours at temperatures ranging from 80°C to 150°C, slowing down production.

- Thermal Stress: High temperatures can stress sensitive components, potentially causing damage if not carefully controlled.

Best Practices for Thermal Curing: Use a controlled ramp-up and cool-down process to minimize thermal shock to components. For example, increase the temperature gradually over 10-15 minutes to the target range (e.g., 120°C) and maintain it for the recommended curing time, often 1-2 hours for silicone coatings.

3. Conformal Coating Moisture Curing: Simplicity in Ambient Conditions

Moisture curing relies on the ambient humidity in the environment to trigger the curing process. This method is often used for silicone-based coatings, where water molecules in the air react with the coating material to form a solid layer.

Advantages of Moisture Curing:

- No Special Equipment: Since it relies on ambient conditions, there’s no need for ovens or UV lamps, reducing setup costs.

- Energy Efficient: No external energy source is required, making it an eco-friendly option.

Challenges:

- Unpredictable Curing Time: Curing can take 24 to 72 hours or longer, depending on humidity levels (ideal range: 40-60% relative humidity) and temperature (ideal: 20-25°C).

- Inconsistent Results: Variations in environmental conditions can lead to uneven curing or incomplete hardening.

Best Practices for Moisture Curing: Maintain a controlled environment with stable humidity and temperature to ensure consistent results. If faster curing is needed, consider using a humidity chamber to accelerate the process by maintaining 50% humidity at 25°C, reducing curing time to under 24 hours.

Factors Affecting Conformal Coating Curing Time

Curing time is a critical parameter that varies across different methods and materials. Understanding the factors that influence conformal coating curing time can help you optimize your process for efficiency and quality.

1. Coating Material: Different materials have unique curing profiles. For instance, acrylic coatings used in UV curing harden in seconds, while silicone coatings in moisture curing may take days.

2. Thickness of Coating: Thicker coatings, often applied at 50-250 micrometers, require longer curing times to ensure complete hardening. For thermal curing, a 100-micrometer layer might need 1 hour at 120°C, while a 200-micrometer layer could require 2 hours.

3. Environmental Conditions: Temperature and humidity play a significant role, especially in moisture curing. Higher humidity (above 50%) can reduce curing time, but excessive moisture can cause defects like bubbling.

4. Equipment Settings: In UV curing, the intensity and exposure time of the lamp directly affect curing speed. A lamp with 200 mW/cm2 intensity can cure a coating in 15 seconds, while a weaker 100 mW/cm2 lamp might take 30 seconds.

Optimization Tip: Always refer to the coating manufacturer’s datasheet for recommended curing times and conditions. Testing small batches under controlled settings can help fine-tune the process before full-scale production.

Choosing the Right Curing Method for Your Needs

Selecting the best conformal coating curing method depends on your specific application, production volume, and budget. Here’s a quick guide to help you decide:

- High-Speed Production: Opt for UV curing if you need fast turnaround times and have the budget for equipment. It’s perfect for consumer electronics with tight deadlines.

- Complex Boards with Hidden Areas: Choose thermal curing to ensure complete coverage, especially for industrial or automotive applications where reliability is paramount.

- Low-Cost, Small-Scale Production: Moisture curing is ideal for low-budget operations or prototypes, as it requires minimal investment in equipment.

Hybrid approaches, such as combining UV and moisture curing, can also address specific challenges like shadow areas while maintaining efficiency.

Common Pitfalls in Conformal Coating Curing and How to Avoid Them

Even with the best methods, mistakes in the curing process can compromise the coating’s effectiveness. Here are some common issues and solutions:

1. Incomplete Curing: This often happens with UV curing in shadowed areas or with moisture curing in low-humidity environments. Solution: Use dual-cure coatings or ensure proper environmental controls.

2. Cracking or Peeling: Over-curing or rapid temperature changes in thermal curing can cause stress in the coating. Solution: Follow a gradual heating and cooling profile, keeping temperature changes below 2°C per minute.

3. Uneven Thickness: Poor application techniques can lead to inconsistent curing. Solution: Use automated spraying or dipping methods for uniform coating thickness before curing.

Advanced Tips for Optimizing Conformal Coating Curing Processes

For engineers looking to take their curing process to the next level, consider these advanced strategies:

- Inline Monitoring: Use real-time monitoring systems to track curing parameters like temperature, humidity, or UV intensity. This ensures consistency across batches.

- Material Testing: Conduct adhesion and hardness tests post-curing to verify the coating’s performance. For instance, a pencil hardness test can confirm if the coating meets the expected 2H-3H rating.

- Custom Curing Profiles: Tailor curing conditions to your specific coating and PCB design. For thermal curing, experiment with temperature ramps (e.g., 5°C/minute up to 100°C) to minimize stress on components.

Conclusion: Achieving the Perfect Finish with ALLPCB

Optimizing conformal coating curing processes is essential for ensuring the reliability and longevity of your PCBs. Whether you choose UV curing for speed, thermal curing for thoroughness, or moisture curing for simplicity, understanding the nuances of each method and fine-tuning factors like curing time can make all the difference. By avoiding common pitfalls and implementing best practices, you can achieve a flawless finish that protects your electronics from even the harshest environments.

At ALLPCB, we’re committed to supporting your manufacturing needs with high-quality solutions and expert guidance. Our advanced facilities and experienced team can help you select and apply the best conformal coating and curing methods for your projects. Trust us to deliver precision and reliability every step of the way.

ALLPCB

ALLPCB