Introduction

As smart construction sites and unmanned construction advance, the digital transformation of tunnel construction equipment has become a focal point. Based on frequent client requirements and recurring scenario challenges, this article presents a customized high-performance multimodal data capture solution for tunnel transport equipment, using an MSV wheeled vehicle as an example.

01 Client Requirements and Scenario Pain Points

Challenging operating environment and vehicle configuration

The target platform is an MSV wheeled vehicle used for TBM tunnel material transport. The vehicle operates for extended periods inside long, confined tunnels and requires two independent perception systems mounted at the vehicle's front and rear to support bidirectional operation.

Multimodal sensor fusion

To achieve comprehensive environment perception, the vehicle integrates a complex sensor suite, including:

- Vision sensors: Huayang GMSL2 3M cameras, 4 channels (front and rear)

- LiDAR: primary LiDAR plus blind-spot LiDARs, total 6 units (front and rear)

- Millimeter-wave radar: ARS410, 2 units (front and rear)

- Positioning and attitude: IMU hwt905-CAN, 2 units (front and rear)

- Vehicle bus: CAN data acquisition

Core challenge: time-space synchronization inside tunnels

- No GPS signal: satellite-based timing (GPS/GNSS) is unavailable inside tunnels, so PPS/NMEA-dependent synchronization methods fail.

- High concurrent bandwidth: multiple LiDARs and high-resolution cameras create large simultaneous data flows, stressing acquisition bandwidth and write speed.

- Harsh operating conditions: strong vibration and heavy dust require industrial-grade stability and ruggedness.

02 Solution Overview

Two differentiated technical routes are proposed to address the above challenges: an extreme-performance hardware-synchronized solution (Option 1) and a cost-effective software-synchronized solution (Option 2), to meet different development-stage requirements.

Option 1: Industrial hardware hard-synchronization

The industrial hard-synchronization solution (BRICKplus + MDILink) uses a data acquisition ecosystem targeting hardware-level time synchronization and high reliability.

Core compute and storage

Use a BRICKplus industrial controller paired with an 8 TB BRICK STORAGE module. The hardware supports wide-temperature operation, high shock resistance, and is designed for vehicle-mounted environments.

BRICKplus equipped with BMC-ETH6000 and CAN expansion modules

Lossless data ingress

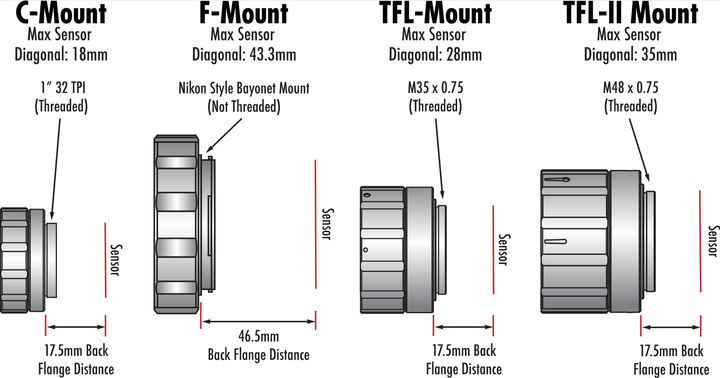

MDILink converters perform lossless conversion of camera GMSL2 signals to 10 Gb/1 Gb Ethernet. SerDes converters adapt sensors with interfaces such as GMSL, CSI-2, and FPDLink, decoupling raw data and timestamps without loss. Receiver software can convert RAW streams into AVI/MP4 for analysis. Time synchronization supports IEEE 802.1AS.

CAN/CAN-FD data are acquired via a TE CAN combo module.

MDILink

TE CAN combo module

Microsecond-level hardware synchronization (gPTP)

To address the lack of GPS, this option uses gPTP hardware time synchronization based on an X TSS-compatible protocol. BRICKplus acts as the master clock and synchronizes LiDARs, MDILink, and CAN modules to sub-microsecond precision, without reliance on external satellite signals.

Closed-loop data offload

Equipped with a BRICK THUNDER DOCK, the system supports rapid data offload via Thunderbolt 3 or 10 Gb Ethernet, significantly shortening time to data availability.

Summary of advantages and limitations:

- Advantages: excellent hardware compatibility, microsecond-level synchronization accuracy, strong data security, rugged design suitable for harsh environments, and reduced integration effort.

- Limitations: relatively higher hardware cost.

Option 2: Flexible software-synchronization

The flexible software-synchronization solution (ECX-3800 + PCIe capture cards) pairs a high-performance commercial industrial computer with professional PCIe capture cards. It is suitable for cost-sensitive projects that can accept software-level synchronization precision.

System architecture diagram

High-performance compute platform

Use an ECX-3800 PEG system with an Intel i7-13700E processor and 64 GB DDR5 memory to provide robust on-board processing capability.

Standardized modular acquisition

Video capture: use a YouSight Proframe 3.0 capture card supporting 4 GMSL2 inputs. CAN capture: use a PCAN-PCI Express FD 4-channel card connected via PCIe.

Millisecond-level software synchronization

In the absence of hardware PTP support, software-level timestamp alignment is used. Middleware such as ROS/ROS2 adjusts timestamps across data streams, achieving millisecond-level precision.

Convenient storage

Use standard SATA-connected 8 TB SSDs (for example, 2.5-inch SATA drives supporting hot-swap) for straightforward disk replacement and maintenance.

Summary of advantages and limitations:

- Advantages: flexible configuration, significantly lower hardware cost (approximately 40% of Option 1), easier maintenance and component replacement.

- Limitations: software synchronization only provides millisecond-level accuracy, which may introduce alignment errors in highly dynamic scenarios; requires more integration and development effort.

03 Software Ecosystem and Visualization

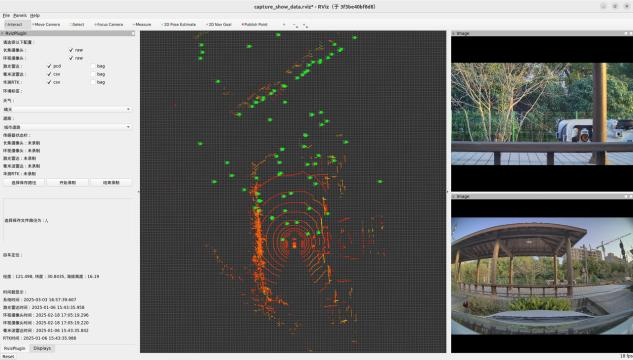

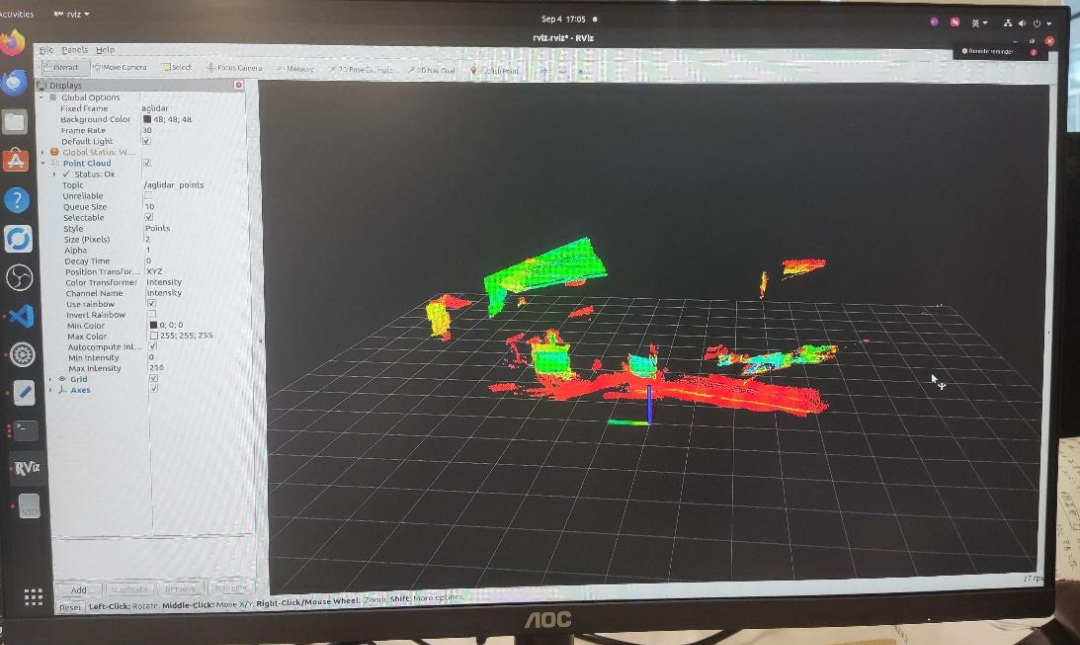

Both hardware options can be supported by a complete ROS/ROS2-based software stack.

- Real-time monitoring: a custom supervisory PC client supports real-time monitoring of all sensor statuses.

- Data visualization: integrates with Rviz to display LiDAR point clouds, camera images, and fused results in real time to facilitate on-site debugging.

- Data storage: supports rosbag recording and conversion of RAW data to AVI/MP4 formats via the supervisory client.

04 Recommendations and Selection Guide

Final solution selection should return to the engineering requirements of the deployment scenario:

- Synchronization precision: lack of GPS inside tunnels is the main constraint. If vehicle speeds are low, millisecond-level software synchronization is generally acceptable. For high-speed automated driving algorithm validation, hardware-synchronized Option 1 is recommended.

- Environmental robustness: considering dust, humidity, and vibration at tunnel construction sites, the fully enclosed, cable-stacked design of Option 1 provides clear reliability advantages and has been used in mature automotive applications.

Implementation suggestions:

- Option 1 is suitable as the preferred choice for benchmark projects where data quality and development risk reduction are primary concerns.

- Option 2 is appropriate for budget-constrained or mass-replicated deployments, but perform thorough PoC testing to validate software synchronization stability in tunnel conditions.

ALLPCB

ALLPCB