In today’s electronics manufacturing world, ensuring your assembly process is lead-free certified is not just a trend—it’s a necessity. With strict regulations like RoHS (Restriction of Hazardous Substances) in place, lead-free assembly has become a standard for producing safe, environmentally friendly, and compliant products. But is your assembly process truly ready for lead-free certification? This blog post will break down everything you need to know about lead-free certification, including the processes, standards, and checklists to help you achieve compliance. Whether you’re focusing on lead-free reflow soldering certification, lead-free wave soldering certification, lead-free hand soldering certification, or lead-free component certification, we’ve got you covered with practical insights and actionable steps.

Why Lead-Free Certification Matters in PCB Assembly

Lead-free certification ensures that your PCB assembly processes and products comply with global environmental and safety regulations. Lead, a toxic substance, was once widely used in soldering for its low melting point and reliability. However, due to health and environmental concerns, regulations like RoHS, introduced in 2006 by the European Union, limit the use of hazardous materials, including lead, to less than 0.1% by weight in electronic components. Non-compliance can result in restricted market access, hefty fines, and damage to your reputation.

Beyond compliance, adopting a lead-free assembly process offers benefits like improved product reliability under higher operating temperatures and a positive brand image for being eco-friendly. However, transitioning to or maintaining a lead-free process requires understanding specific certifications and standards for each stage of assembly, from reflow soldering to component selection. Let’s dive into the key aspects of lead-free certification and how to prepare your assembly process.

What Is Lead-Free Certification?

Lead-free certification verifies that your PCB assembly processes and materials meet the required standards for minimal lead content. This certification covers various soldering techniques, including reflow soldering, wave soldering, and hand soldering, as well as the components used in manufacturing. It often aligns with standards set by organizations like the International Electrotechnical Commission (IEC) and directives like RoHS.

Certification is not a one-size-fits-all process. It involves specific training, equipment adjustments, and material selections tailored to each type of soldering or component handling. For instance, lead-free solders, such as SAC305 (a common tin-silver-copper alloy), require higher melting temperatures—typically around 217-220°C compared to 183°C for traditional leaded solder. This difference impacts equipment settings, thermal profiles, and worker skills, all of which must be addressed to achieve certification.

Lead-Free Assembly Process Checklist: Are You Ready?

To ensure your assembly process is ready for lead-free certification, you need a comprehensive checklist that covers materials, equipment, training, and documentation. Below is a detailed lead-free assembly process checklist to guide you through the preparation:

- Material Selection: Verify that all solder pastes, wires, and components are lead-free and RoHS-compliant. Check supplier documentation for lead content specifications (less than 0.1% by weight).

- Equipment Compatibility: Ensure your soldering equipment can handle higher temperatures (up to 260°C for reflow ovens) and has precise thermal control to prevent component damage.

- Process Validation: Develop and test thermal profiles for each assembly process to avoid issues like cold solder joints or thermal shock to components.

- Training and Certification: Train staff in lead-free soldering techniques and certify them through recognized programs like IPC standards (more on this below).

- Quality Control: Implement inspection methods, such as X-ray imaging, to detect soldering defects unique to lead-free processes, like voids or insufficient wetting.

- Documentation: Maintain records of material certifications, process parameters, and employee training for audit purposes.

Using this checklist as a starting point will help identify gaps in your current process and prepare you for certification audits. Each item ties directly to the specific soldering methods and component standards we’ll explore next.

Lead-Free Reflow Soldering Certification: Key Requirements

Lead-free reflow soldering certification focuses on the process of soldering surface-mount components to PCBs using a reflow oven with lead-free solder paste. This method requires precise control over temperature profiles because lead-free solders melt at higher temperatures, often between 217°C and 220°C, compared to traditional solders. Certification ensures that your reflow process meets industry standards like IPC-A-610 (Acceptability of Electronic Assemblies) and J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies).

To achieve certification, you must:

- Optimize Thermal Profiles: Create a reflow profile with a peak temperature of around 245-260°C and a time above liquidus (TAL) of 60-90 seconds to ensure proper solder joint formation without damaging components.

- Use Compatible Materials: Select lead-free solder pastes (e.g., SAC305) and ensure PCB finishes like ENIG (Electroless Nickel Immersion Gold) are compatible with high-temperature soldering.

- Train Operators: Certify staff through IPC training programs to handle lead-free reflow soldering challenges, such as managing tombstoning or insufficient wetting.

- Inspect Results: Use automated optical inspection (AOI) to check for defects like voids, which are more common in lead-free soldering due to higher surface tension.

Certification for reflow soldering often involves third-party audits or internal compliance checks to verify that your process consistently produces reliable, lead-free solder joints.

Lead-Free Wave Soldering Certification: What You Need to Know

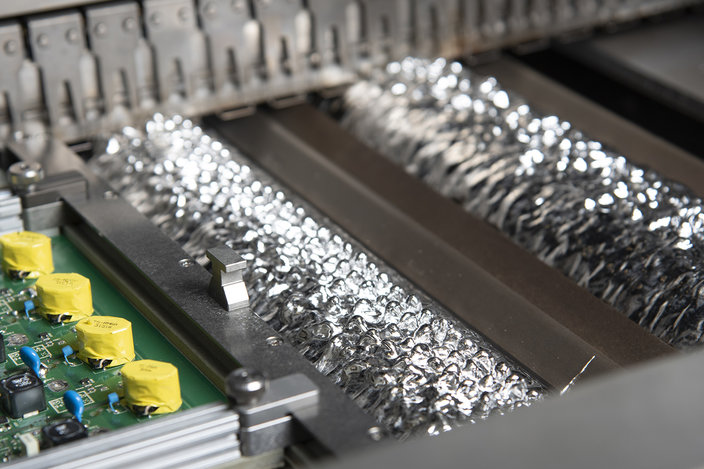

Lead-free wave soldering certification applies to through-hole component assembly, where a wave of molten solder bonds components to the PCB. Like reflow soldering, wave soldering with lead-free materials requires higher temperatures (typically 260-270°C) and different flux formulations to ensure proper wetting and joint strength.

Key steps to achieve certification include:

- Adjust Solder Pot Temperature: Set the solder bath to maintain a stable temperature around 265°C to accommodate lead-free alloys like SAC305.

- Select Proper Flux: Use fluxes designed for lead-free soldering to improve wettability and reduce dross formation, which can increase by 30-50% compared to leaded soldering.

- Control Conveyor Speed: Adjust the conveyor speed to ensure contact time with the solder wave is sufficient (usually 2-4 seconds) for strong joints without thermal stress.

- Certify Operators: Train staff on lead-free wave soldering techniques and certify them under IPC standards to minimize defects like bridging or insufficient fill.

Certification ensures your wave soldering process meets quality and safety standards, reducing the risk of field failures due to poor solder joints.

Lead-Free Hand Soldering Certification: Skills and Standards

Lead-free hand soldering certification is critical for rework, repair, or small-scale assembly tasks. Hand soldering with lead-free materials is more challenging due to higher melting points and reduced wettability, which can lead to cold joints or component damage if not done correctly.

To achieve certification, focus on:

- Tool Selection: Use soldering irons with adjustable temperature settings capable of reaching 300-350°C to melt lead-free solder effectively.

- Skill Development: Train technicians to apply the correct amount of heat and solder, avoiding prolonged exposure that could damage components (e.g., thermal stress on capacitors).

- IPC Certification: Enroll in IPC hand soldering courses like IPC-7711/7721 (Rework, Modification, and Repair of Electronic Assemblies) to gain recognized credentials.

- Quality Inspection: Inspect hand-soldered joints visually or with magnification to ensure they meet IPC-A-610 standards for appearance and reliability.

Certified hand soldering ensures that even manual repairs maintain the integrity of your lead-free assembly process, preserving product reliability.

Lead-Free Component Certification: Ensuring Compliance from the Start

Lead-free component certification verifies that the components used in your PCB assembly are free from restricted substances like lead. This certification is often provided by component manufacturers and must comply with RoHS directives. As a PCB assembler, you need to ensure that every component—resistors, capacitors, ICs, and connectors—comes with proper documentation.

Steps to ensure component compliance include:

- Supplier Verification: Request Material Safety Data Sheets (MSDS) or RoHS compliance certificates from suppliers for each component batch.

- Testing: Use X-ray fluorescence (XRF) analyzers to test components for lead content, ensuring levels are below 0.1% by weight.

- Traceability: Maintain records of component origins and compliance documents for audits or regulatory checks.

- Labeling: Ensure components are marked as lead-free (often with a “Pb-free” symbol) to avoid mix-ups during assembly.

Using certified lead-free components is the foundation of a compliant assembly process, preventing issues down the line during soldering or final product testing.

Challenges in Transitioning to Lead-Free Assembly

Switching to or maintaining a lead-free assembly process isn’t without challenges. Higher soldering temperatures can stress components, leading to issues like delamination or cracking if thermal profiles aren’t optimized. Lead-free solders also tend to form more brittle joints, increasing the risk of failure under mechanical stress. Additionally, the cost of lead-free materials and compatible equipment can be 20-30% higher than traditional options, impacting budgets for smaller manufacturers.

However, these challenges can be mitigated with proper planning:

- Invest in robust training programs to equip staff with the skills needed for lead-free processes.

- Upgrade equipment to handle higher temperatures and ensure precise control.

- Partner with reliable suppliers for certified lead-free materials to avoid quality issues.

How to Get Started with Lead-Free Certification

Ready to certify your assembly process? Follow these steps to streamline the journey:

- Assess Current Processes: Use the lead-free assembly process checklist provided earlier to identify areas needing improvement.

- Choose a Certification Body: Work with recognized organizations like IPC for training and certification in soldering techniques and standards.

- Train Your Team: Enroll employees in courses for reflow, wave, and hand soldering to build expertise in lead-free methods.

- Conduct Internal Audits: Regularly review your processes and materials to ensure ongoing compliance before external audits.

- Document Everything: Keep detailed records of training, material certifications, and process parameters for transparency during certification.

Certification is an ongoing commitment, not a one-time achievement. Regular updates to training and equipment will keep your process aligned with evolving standards and regulations.

Benefits of Lead-Free Certification for Your Business

Achieving lead-free certification offers several advantages beyond compliance:

- Market Access: Gain entry to regions with strict regulations, such as the EU, where RoHS compliance is mandatory.

- Customer Trust: Demonstrate your commitment to safety and sustainability, building confidence among clients.

- Product Reliability: Lead-free soldering often results in stronger joints under high-temperature conditions, improving product lifespan.

- Environmental Impact: Reduce hazardous waste, contributing to a greener manufacturing footprint.

Conclusion: Prepare Today for a Lead-Free Future

Lead-free certification is a critical step for any electronics manufacturer aiming to stay competitive and compliant in today’s market. By following a detailed lead-free assembly process checklist and pursuing certifications like lead-free reflow soldering certification, lead-free wave soldering certification, lead-free hand soldering certification, and lead-free component certification, you can ensure your assembly process meets global standards. The journey may involve challenges like higher costs and process adjustments, but the benefits of compliance, reliability, and customer trust far outweigh the hurdles.

Start by assessing your current setup, training your team, and partnering with trusted suppliers for certified materials. With the right preparation, your assembly process will not only be ready for lead-free certification but also positioned for long-term success in a sustainable electronics industry.

ALLPCB

ALLPCB