In the world of electronics, creating efficient and reliable printed circuit boards (PCBs) often means combining the strengths of different assembly technologies. Hybrid PCB assembly, which integrates Through-Hole Technology (THT) and Surface Mount Technology (SMT), offers a powerful solution. This approach, often referred to as mixed technology PCBs, brings together the durability of THT and the compactness of SMT to meet diverse design needs. In this blog, we'll explore how the THT and SMT combination works, its benefits, and best practices for achieving optimal results in hybrid PCB assembly.

What Is Hybrid PCB Assembly?

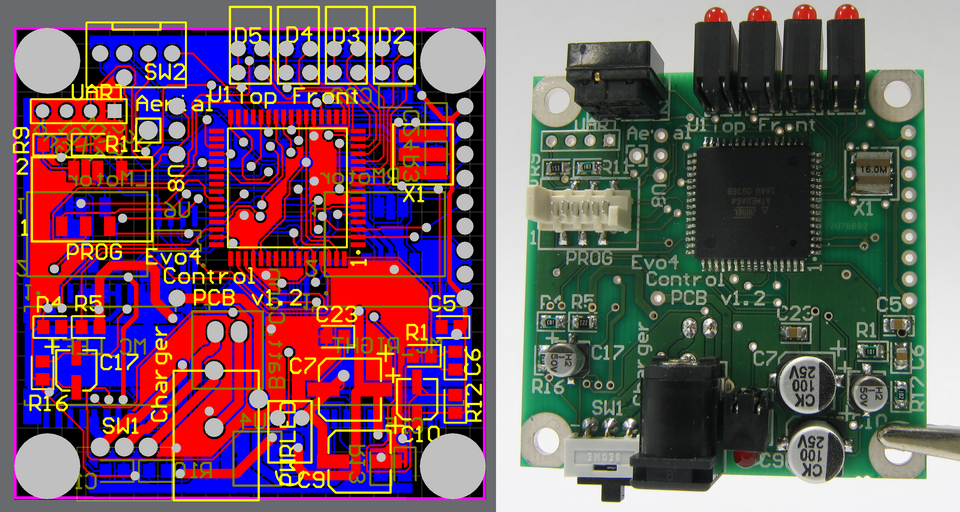

Hybrid PCB assembly refers to the process of combining THT and SMT components on a single board. THT involves inserting component leads through holes in the PCB and soldering them on the opposite side, providing strong mechanical bonds. SMT, on the other hand, places components directly onto the surface of the PCB, allowing for smaller, denser designs. By using both methods, mixed technology PCBs can leverage the unique advantages of each, catering to complex applications where neither technology alone would suffice.

This combination is ideal for designs that require both high reliability and compact layouts. For instance, a power supply board might use THT for large capacitors and connectors that need to withstand mechanical stress, while SMT handles smaller resistors and integrated circuits for space efficiency. Let’s dive deeper into why this approach is often the best of both worlds.

Why Choose a THT and SMT Combination?

The decision to use hybrid PCB assembly comes down to balancing performance, cost, and design requirements. Here are the key reasons why a THT and SMT combination is often the ideal choice for mixed technology PCBs:

- Enhanced Durability and Reliability: THT components are known for their robust mechanical connections. They can handle high levels of vibration and stress, making them perfect for applications like automotive or industrial electronics. For example, a THT connector might endure forces up to 10N without failure, compared to SMT components which may struggle under similar conditions.

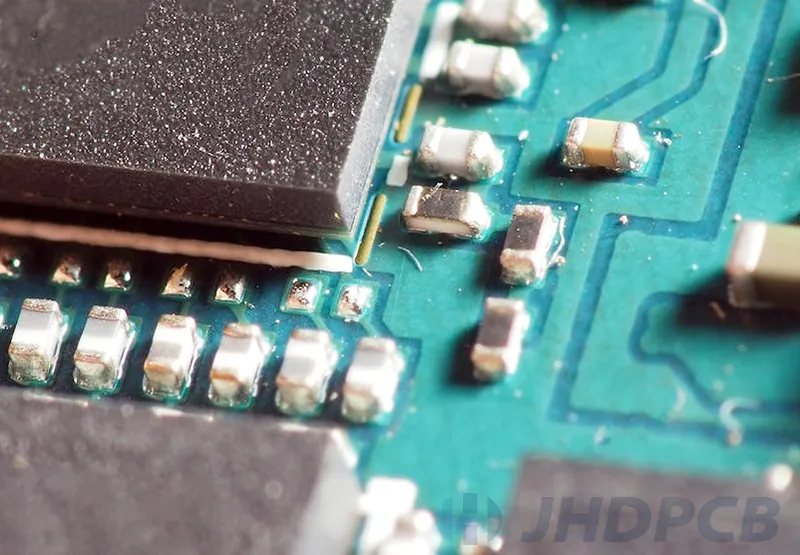

- Space Efficiency: SMT allows for higher component density, reducing the overall size of the PCB. This is critical in modern devices like smartphones or wearables, where board space is limited. SMT components can be placed at densities of up to 50 components per square inch, far surpassing THT capabilities.

- Versatile Component Selection: Not all components are available in both THT and SMT formats. Hybrid assembly ensures you can use the best component for the job, regardless of mounting type. For instance, high-power transformers often come in THT packages, while microcontrollers are predominantly SMT.

- Cost-Effective for Mixed Needs: By combining automated SMT assembly with selective THT insertion, manufacturers can optimize production costs. SMT automation speeds up placement for small components, while THT handles larger parts that may require manual insertion.

Applications of Mixed Technology PCBs

Mixed technology PCBs are widely used across industries where diverse performance requirements must be met. Here are some common applications of hybrid PCB assembly:

- Power Electronics: Devices like power supplies and inverters often use THT for high-current components such as capacitors and inductors, while SMT handles control circuitry. This ensures both thermal management and compact design.

- Automotive Systems: In automotive control units, THT provides durability for connectors exposed to vibration, while SMT supports the dense layout of microprocessors and sensors.

- Medical Devices: Equipment like patient monitors may use SMT for miniature sensors and processors, combined with THT for reliable power connectors that can be frequently plugged and unplugged.

- Industrial Controls: Hybrid assembly is common in PLCs (Programmable Logic Controllers), where THT ensures robust connections for relays, and SMT enables compact logic circuits.

These examples highlight how the THT and SMT combination addresses specific needs, making hybrid PCB assembly a versatile solution for complex projects.

Challenges in Hybrid PCB Assembly

While the benefits of mixed technology PCBs are clear, integrating THT and SMT does come with challenges. Understanding these hurdles is key to achieving a successful design and assembly process.

- Thermal Stress During Soldering: SMT components are typically soldered using reflow ovens at temperatures around 260°C, which can stress THT components if not managed properly. Wave soldering for THT, on the other hand, may affect SMT parts if they are on the same side of the board.

- Design Complexity: Combining two mounting technologies requires careful PCB layout planning. For instance, THT holes must not interfere with SMT pads, and spacing must account for both component types to avoid signal interference or crosstalk, which can degrade performance at high frequencies (e.g., above 100 MHz).

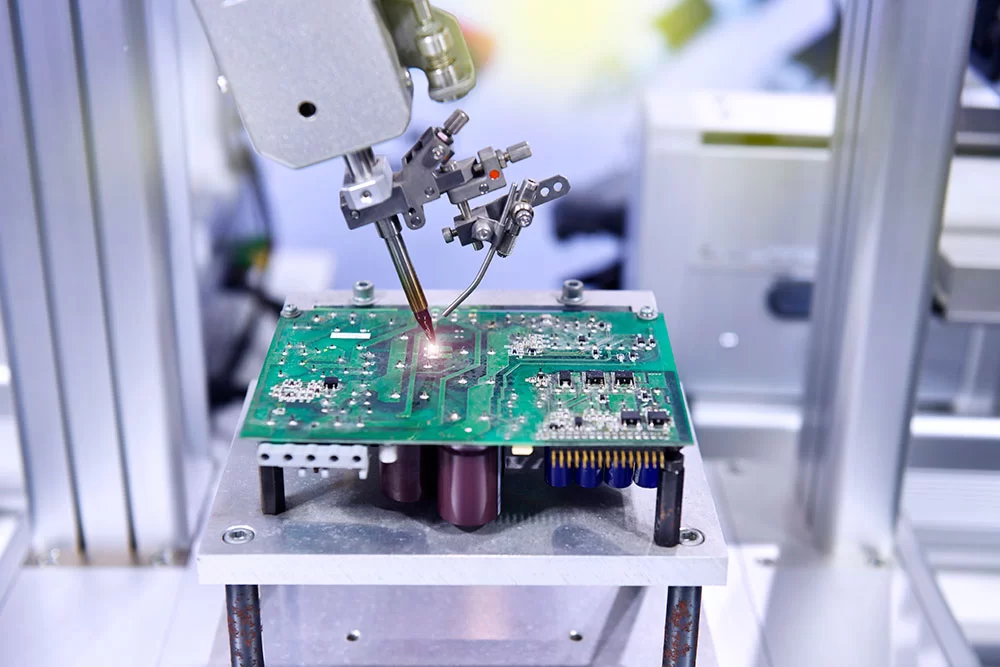

- Assembly Sequencing: Hybrid PCB assembly often requires multiple steps, such as SMT placement followed by THT insertion. Misalignment in sequencing can lead to component damage or poor solder joints.

- Testing and Inspection: Ensuring quality in mixed technology PCBs can be tricky. SMT components often require X-ray inspection for hidden solder joints (e.g., under BGA packages), while THT joints need visual or automated optical inspection for fillet quality.

Best Practices for Hybrid PCB Assembly

To overcome the challenges of the THT and SMT combination, following best practices is essential. These guidelines will help ensure your mixed technology PCBs are reliable and efficient.

1. Optimize PCB Layout for Both Technologies

Start with a well-thought-out PCB layout. Keep THT components in areas that won’t interfere with SMT placement. For example, place THT connectors near board edges for easy access, while grouping SMT components in denser central areas. Maintain clearance of at least 0.5 mm between THT holes and SMT pads to prevent soldering issues. Additionally, consider signal integrity by routing high-speed traces (e.g., with impedance of 50 ohms) away from THT holes to minimize interference.

2. Plan Soldering Processes Carefully

Sequence the assembly to minimize thermal stress. Typically, SMT components are placed and reflow-soldered first, followed by THT insertion and wave soldering. If both sides of the PCB have components, use selective soldering for THT to avoid damaging SMT parts. Ensure temperature profiles are controlled—limit reflow peaks to 245-260°C for SMT and keep wave soldering below 270°C for THT to protect component integrity.

3. Choose Components Wisely

Select components based on their intended function and availability. Use THT for parts that require mechanical strength, like heavy capacitors or connectors rated for currents above 5A. Opt for SMT for smaller, high-density components like resistors or ICs with pin pitches below 0.5 mm. Check datasheets to confirm thermal and electrical compatibility between THT and SMT parts on the same board.

4. Implement Robust Quality Control

Quality assurance is critical in hybrid PCB assembly. Use automated optical inspection (AOI) to check SMT solder joints for defects like tombstoning or insufficient solder. For THT, verify solder fillets meet IPC-A-610 standards, ensuring a concave shape with at least 75% coverage around the lead. X-ray inspection can help detect voids in SMT joints under packages like QFN or BGA, where defects can cause failures at high frequencies (e.g., above 1 GHz).

5. Test for Environmental Stress

Hybrid PCBs often face varied operating conditions. Conduct thermal cycling tests between -40°C and 85°C to ensure solder joints withstand expansion and contraction. Vibration testing at frequencies up to 20 Hz can confirm THT components remain secure in high-stress applications like automotive electronics. These tests help validate the reliability of mixed technology PCBs in real-world scenarios.

Benefits of Partnering with Experts for Hybrid PCB Assembly

Navigating the complexities of the THT and SMT combination can be daunting, especially for intricate designs. Partnering with experienced assembly providers ensures access to advanced equipment, skilled technicians, and streamlined processes. Expertise in hybrid PCB assembly means fewer production errors, faster turnaround times, and adherence to industry standards like IPC. This support is invaluable for projects requiring high reliability and precision, from prototyping to mass production.

Future Trends in Mixed Technology PCBs

As electronics continue to evolve, hybrid PCB assembly is poised to play an even larger role. Emerging trends include the integration of advanced materials to improve thermal management in mixed technology PCBs, allowing them to handle higher power densities (e.g., up to 10 W/cm2). Additionally, automation advancements are making hybrid assembly more cost-effective, with robotic systems capable of handling both THT and SMT placement at speeds exceeding 100,000 components per hour. These innovations promise to further enhance the versatility and efficiency of the THT and SMT combination.

Conclusion

Integrating THT and SMT in hybrid PCB assembly truly offers the best of both worlds. By leveraging the durability of THT and the compactness of SMT, mixed technology PCBs meet the demands of diverse applications, from power electronics to medical devices. While challenges like thermal stress and design complexity exist, following best practices such as optimized layouts, careful soldering, and rigorous quality control ensures success. As technology advances, the THT and SMT combination will continue to drive innovation in electronics, delivering reliable, efficient solutions for complex designs.

Whether you're designing a new product or refining an existing one, hybrid PCB assembly provides the flexibility and performance needed to stay ahead. With the right approach and expertise, your mixed technology PCBs can achieve outstanding results, balancing durability, space, and cost in perfect harmony.

ALLPCB

ALLPCB