According to reports, global Industry 4.0 product and services spending is expected to rise from $119 billion in 2020 to $310 billion in 2023, a compound annual growth rate of 27.04%. By 2030, the Internet of Things could add $14.2 trillion to the global economy.

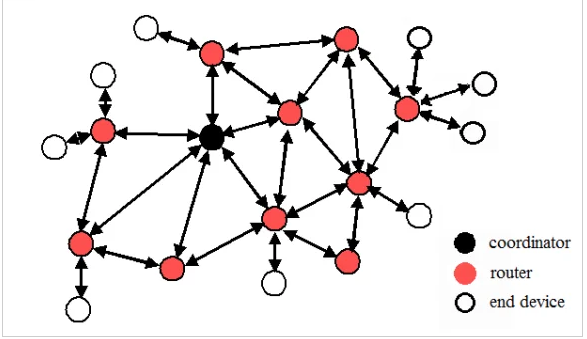

Although IoT is common in consumer applications, its primary focus is industrial use cases such as manufacturing, supply chain monitoring, and management. The "industrial" aspect in manufacturing covers a range of use cases that use connected intelligent things to link the physical and digital worlds and drive the development of connected factories.

Automation

Factory automation is not new, but the connected era has arrived. Automation in IoT essentially describes the evolution toward fully digital environments enabled by artificial intelligence and sensors, allowing companies to adopt advanced capabilities and realize meaningful returns. Sensors on machines or assets are always on, collecting data even when human staff are off shift. In a connected IoT factory, machines can automatically adjust input variables, enabling automation across industrial processes. This approach is especially suitable for repetitive tasks that must be performed quickly and frequently, such as assembly-line work, freeing human attention for more complex or difficult tasks.

Remote Monitoring and Predictive Maintenance

IoT also changes how factories perform maintenance. The technology is designed to assess equipment condition to estimate when maintenance will be required. These processes have, on average, increased uptime by 9%, reduced costs by 12%, lowered safety/health/environment/quality risks by 14%, and extended the life of aging assets by 20%.

By leveraging various IoT sensors, remote monitoring can now collect real-time data to compile actionable insights and inform critical planning in smart factories. Do machines need maintenance, to be powered on, or to be powered off? Does production speed need adjustment? Machines can now not only detect warning signals but also trigger alerts and initiate self-protection. With IoT, it is possible to take proactive measures before disruptive events affect operations.

Traceability

Traceability improves efficiency and helps locate tools and parts more accurately. For time-sensitive components, it ensures they are used within their shelf life, and more precise factory procurement helps address overstock and shortage issues.

Worker Safety

Workers are the most important asset in a factory. Factories involve hazards because they require heavy machinery and its operation to keep everything running smoothly. Especially during the COVID-19 era, knowing where people are in a plant, their distances from each other, and the activities they typically perform is critical for health and safety. IoT applications can help prevent workplace injuries and limit the spread of infectious diseases.

ALLPCB

ALLPCB