When it comes to PCB silk screen printing, selecting the right board type is a crucial step that can impact the quality, functionality, and durability of the final product. The board type influences how well the silk screen layer—used for labeling components, test points, and other critical information—adheres to the surface, as well as how clearly the markings appear. Factors like the material of the board, compatibility with the printing process, and the use of transparent paper for design transfers all play a role in this decision. In this comprehensive guide, we’ll walk you through the essentials of choosing the right board type for PCB silk screen printing, with a focus on transparent paper, printing materials, and the printing process.

Why Board Type Matters in PCB Silk Screen Printing

The silk screen layer on a printed circuit board (PCB) is more than just a visual aid; it serves as a critical reference for assembly, testing, and troubleshooting. This layer typically includes labels for components, polarity indicators, and warning symbols. However, the effectiveness of this layer depends heavily on the board type you choose. The material and surface finish of the board can affect ink adhesion, clarity of the printed markings, and even the longevity of the silk screen layer under various environmental conditions.

For instance, a board with a smooth surface finish may allow for sharper and more precise silk screen printing, while a rougher surface might cause ink to spread unevenly. Additionally, the board material can influence how well it withstands the printing process, especially if high temperatures or specific chemicals are involved. Understanding these factors ensures that the silk screen layer remains legible and functional throughout the PCB’s lifecycle.

Key Factors to Consider When Selecting a Board Type

Choosing the right board type for PCB silk screen printing involves evaluating several key factors. Below, we break down the most important considerations to guide your decision-making process.

1. Board Material Compatibility with Silk Screen Ink

The material of the PCB is one of the primary factors to consider. Most PCBs are made from materials like FR-4, a fiberglass-reinforced epoxy laminate, which is widely used due to its durability and cost-effectiveness. FR-4 generally provides a good surface for silk screen printing, as it allows for strong ink adhesion when paired with the right type of ink, such as non-conductive epoxy-based inks commonly used in the industry.

However, other materials like polyimide, used for flexible PCBs, or ceramic substrates, used in high-temperature applications, may require specialized inks or printing processes. For instance, polyimide boards might need a specific ink formulation to ensure adhesion on their flexible surface, while ceramic boards could require inks that can withstand extreme heat during curing. Always check the compatibility of the board material with the silk screen ink to avoid issues like peeling or fading over time.

2. Surface Finish and Its Impact on Printing Quality

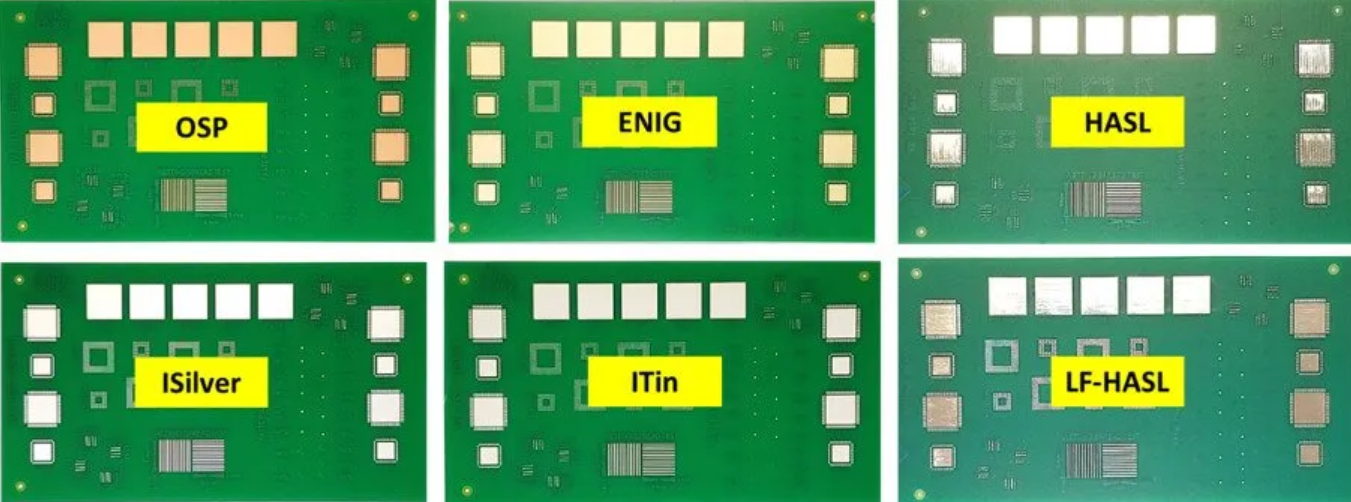

The surface finish of the PCB plays a significant role in the clarity and durability of silk screen printing. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). Each finish affects how the silk screen ink adheres to the board and how well the markings remain visible after assembly and soldering processes.

- HASL: This finish provides a relatively rough surface, which can sometimes cause uneven ink application during silk screen printing. However, it is cost-effective and widely used for standard applications.

- ENIG: Offering a smoother and more uniform surface, ENIG is often preferred for high-precision silk screen printing. It ensures clearer markings and better ink adhesion, making it ideal for complex designs.

- OSP: This finish is environmentally friendly but may not provide the same level of smoothness as ENIG, potentially affecting the sharpness of silk screen details.

Selecting a surface finish that complements the silk screen printing process is essential for achieving high-quality results. For projects requiring intricate markings, a smoother finish like ENIG might be the better choice.

3. Board Thickness and Structural Considerations

The thickness of the PCB can also influence the silk screen printing process. Standard PCB thicknesses range from 0.8mm to 1.6mm, with 1.6mm being the most common for general-purpose boards. Thicker boards provide more structural stability, which can be beneficial during the printing process, especially if manual silk screening methods are used. Thinner boards, while lighter and more flexible, may require additional care to prevent warping or damage during printing.

For applications where transparent paper is used as a stencil or design transfer medium in the silk screen process, board thickness can affect how well the design aligns with the board surface. Thicker boards might be easier to handle during alignment, while thinner boards could require more precise fixturing to avoid misalignment.

4. Environmental and Application-Specific Requirements

The intended application of the PCB and its operating environment should guide your board type selection. For example, if the PCB will be used in a high-humidity or high-temperature environment, you’ll need a board material and surface finish that can withstand these conditions without degrading the silk screen layer. FR-4 boards with an ENIG finish, for instance, are often suitable for such conditions due to their resistance to corrosion and thermal stress.

Additionally, consider whether the PCB will undergo frequent handling or assembly processes. Boards with robust silk screen layers are essential in these scenarios to prevent the markings from wearing off over time. Selecting a board type with a compatible ink and finish can ensure the silk screen remains intact under mechanical stress.

Understanding the Role of Transparent Paper in Silk Screen Printing

Transparent paper often plays a role in the design and preparation stages of silk screen printing, especially in traditional or manual methods. This material is used to create stencils or transfer designs onto the PCB surface before the ink is applied. The use of transparent paper can significantly impact the accuracy and quality of the silk screen layer, so it’s important to understand how it integrates with the board type selection.

Transparent paper is typically used in conjunction with a photo-plotting or imaging process to create a stencil that matches the desired silk screen design. The paper must be compatible with the printing process and the board type to ensure precise alignment and transfer of the design. For instance, when working with FR-4 boards, the transparent paper should have sufficient durability to withstand the handling and alignment process without tearing or distorting.

Moreover, the thickness and opacity of the transparent paper can affect the exposure process if UV light is used to cure the stencil or ink. Thicker or less transparent paper might require longer exposure times, which could impact the overall production timeline. When selecting a board type, consider how the transparent paper will interact with the board’s surface finish and material to achieve the best results.

Exploring Printing Materials for PCB Silk Screen

The choice of printing materials, particularly the ink used for silk screen printing, is closely tied to the board type. Most silk screen inks are non-conductive epoxy-based formulations designed to adhere to PCB surfaces without interfering with electrical functionality. These inks are available in various colors, with white and black being the most common due to their high contrast against typical PCB backgrounds.

When selecting a board type, ensure that the ink material is compatible with the board’s surface finish and material. For example, a board with an ENIG finish might pair well with a high-resolution ink that can produce fine lines and detailed markings. On the other hand, a board with a HASL finish might require a thicker ink application to account for surface irregularities.

Additionally, consider the curing process of the ink. Some inks require high-temperature curing, which might not be suitable for certain board materials like polyimide if they are sensitive to heat. Always match the ink properties with the board type to avoid issues like cracking or poor adhesion during the printing process.

The Printing Process and Its Impact on Board Selection

The silk screen printing process itself can influence the choice of board type. There are several common methods used in the industry, each with its own requirements and compatibility considerations. Below, we outline the main printing processes and how they relate to board selection.

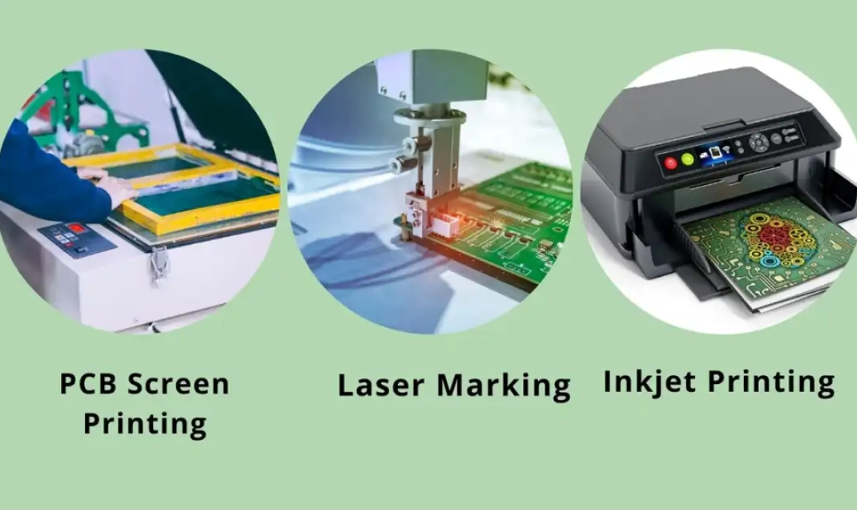

1. Manual Silk Screen Printing

In manual silk screen printing, a stencil (often created using transparent paper) is placed over the PCB, and ink is applied through the stencil using a squeegee. This method is cost-effective for small-scale production but requires a board with a stable and flat surface to ensure even ink application. Thicker boards, such as 1.6mm FR-4, are often preferred for manual printing due to their structural stability.

2. Liquid Photo Imaging (LPI)

Liquid Photo Imaging is a more modern and precise method where a liquid photo-imageable epoxy is coated onto the PCB surface, exposed to UV light through a stencil or film, and then developed and cured. This process is ideal for boards with smooth surface finishes like ENIG, as it allows for high-resolution markings with line widths as fine as 4 mils. When using LPI, ensure the board material can withstand the chemical development and curing stages without degrading.

3. Direct Legend Printing (DLP)

Direct Legend Printing is a highly accurate digital printing method that applies ink directly onto the PCB surface without the need for a stencil. DLP is compatible with a wide range of board types and surface finishes, making it a versatile option for complex designs. However, it may require a smoother surface for optimal results, so boards with finishes like ENIG are often recommended.

Understanding the printing process you’ll be using can help narrow down the board type. For instance, if you’re using LPI or DLP for high-precision markings, prioritize boards with smoother finishes. If manual printing is your method of choice, focus on thicker, more stable board materials to ensure consistency.

Practical Tips for Selecting the Right Board Type

To wrap up, here are some practical tips to help you select the right board type for PCB silk screen printing:

- Match the Board Material to the Application: Choose materials like FR-4 for standard applications or polyimide for flexible PCBs, ensuring compatibility with the silk screen ink and environmental conditions.

- Prioritize Surface Finish for Clarity: Opt for smoother finishes like ENIG for high-resolution silk screen printing, especially if fine details are required.

- Consider Board Thickness: Use thicker boards (e.g., 1.6mm) for stability during manual printing, and thinner boards (e.g., 0.8mm) for lightweight or flexible designs with proper handling.

- Align Printing Process with Board Type: Select a board that suits the printing method, whether it’s manual silk screening with transparent paper stencils or advanced techniques like LPI and DLP.

- Test Compatibility: Before full-scale production, conduct small-scale tests to ensure the board type, ink, and printing process work well together without issues like poor adhesion or unclear markings.

Conclusion

Selecting the right board type during PCB silk screen printing is a decision that requires careful consideration of multiple factors, including board material, surface finish, thickness, and compatibility with the printing process. By understanding how these elements interact with transparent paper, printing materials, and various printing techniques, you can ensure high-quality silk screen markings that enhance the functionality and reliability of your PCB. Whether you’re working on a small prototype or a large-scale production run, taking the time to choose the appropriate board type will pay off in the form of clear, durable, and professional results.

With the insights provided in this guide, you’re well-equipped to make informed decisions that align with your project’s specific needs. Keep these considerations in mind, and you’ll be on your way to achieving exceptional silk screen printing outcomes for your PCBs.

ALLPCB

ALLPCB