When it comes to rework in electronics, choosing the right solder is critical for achieving reliable connections and ensuring the longevity of your components. Whether you're repairing a circuit board or modifying an existing design, the decision between lead-free solder and leaded solder can impact the quality of your work, safety, and compliance with regulations. In this comprehensive guide, we'll dive into the differences between these solder types, focusing on their composition, performance in rework scenarios, and key factors to consider. By the end, you'll have a clear understanding of which solder type best suits your needs for rework projects.

Quick Answer: Lead-Free vs. Leaded Solder for Rework

For most rework tasks, lead-free solder is often the recommended choice due to its compliance with environmental regulations like RoHS (Restriction of Hazardous Substances) and its safer profile for health. However, leaded solder, with its lower melting point and easier handling, can be preferable for specific rework applications where regulations allow and precision is needed. Your decision should balance performance, safety, and legal requirements based on your project.

Now, let’s explore the details of solder types, compositions, and their suitability for rework to help you make an informed choice.

What Are Solder Types and Why Do They Matter for Rework?

Solder is a metal alloy used to create strong electrical and mechanical connections between components on a circuit board. In rework, which involves repairing or modifying existing soldered connections, the type of solder you use can affect the ease of application, durability of the joint, and overall success of the repair. The two primary categories of solder are leaded and lead-free, each with distinct compositions and characteristics.

Rework often requires desoldering (removing old solder) and resoldering components, which demands a solder that matches the original material or performs well under specific conditions. Using the wrong solder type can lead to poor connections, component damage, or even failure of the entire board. Understanding the differences between lead-free and leaded solder is essential for achieving reliable results.

Leaded Solder: Composition and Characteristics

Leaded solder has been a traditional choice in electronics for decades due to its excellent performance and ease of use. Its composition typically includes a mix of tin (Sn) and lead (Pb), with the most common ratio being 63% tin and 37% lead (often referred to as 63/37 solder). This alloy offers specific benefits that make it appealing for rework tasks.

- Low Melting Point: Leaded solder melts at around 183°C (361°F), which is lower than most lead-free alternatives. This lower temperature reduces the risk of damaging heat-sensitive components during rework.

- Good Wetting Properties: It flows smoothly and adheres well to surfaces, creating strong, reliable joints with minimal effort.

- Ease of Rework: Due to its softness and low melting point, leaded solder is easier to desolder and rework compared to lead-free options.

However, leaded solder poses health and environmental risks due to the toxicity of lead. Prolonged exposure to lead fumes during soldering can be harmful, and improper disposal can contaminate the environment. As a result, its use is restricted in many regions under regulations like RoHS, especially for commercial products.

When to Use Leaded Solder for Rework

Leaded solder can be a good choice for rework in specific scenarios:

- Repairing older electronics that originally used leaded solder, as mixing solder types can lead to unreliable joints.

- Projects where regulations permit its use, such as in certain military or aerospace applications exempt from RoHS.

- Situations requiring precise control over heat to avoid damaging delicate components.

Lead-Free Solder: Composition and Characteristics

Lead-free solder emerged as an alternative to meet environmental and health safety standards. Its composition typically includes tin (Sn) combined with other metals like silver (Ag), copper (Cu), or bismuth (Bi). One of the most common lead-free alloys is SAC305, which consists of 96.5% tin, 3% silver, and 0.5% copper.

- Higher Melting Point: Lead-free solder generally melts at higher temperatures, often around 217-220°C (422-428°F) for SAC305. This can pose challenges during rework, as it requires more heat and may risk damaging components.

- Environmental Compliance: It meets RoHS and similar regulations, making it suitable for most modern electronics manufacturing and rework.

- Durability: Lead-free joints are often stronger and more resistant to thermal fatigue, which can be beneficial for long-term reliability.

Despite its advantages, lead-free solder can be more difficult to work with during rework. Its higher melting point and poorer wetting properties compared to leaded solder can result in a steeper learning curve for technicians. Additionally, the risk of "tin whiskers"—tiny, hair-like growths that can cause short circuits—is slightly higher with some lead-free alloys.

When to Use Lead-Free Solder for Rework

Lead-free solder is often the preferred choice for rework in the following cases:

- Repairing or modifying modern electronics that comply with RoHS standards, as most new devices use lead-free solder.

- Projects where environmental and health safety are priorities.

- Applications requiring high reliability under thermal stress, as lead-free solder often performs better in such conditions.

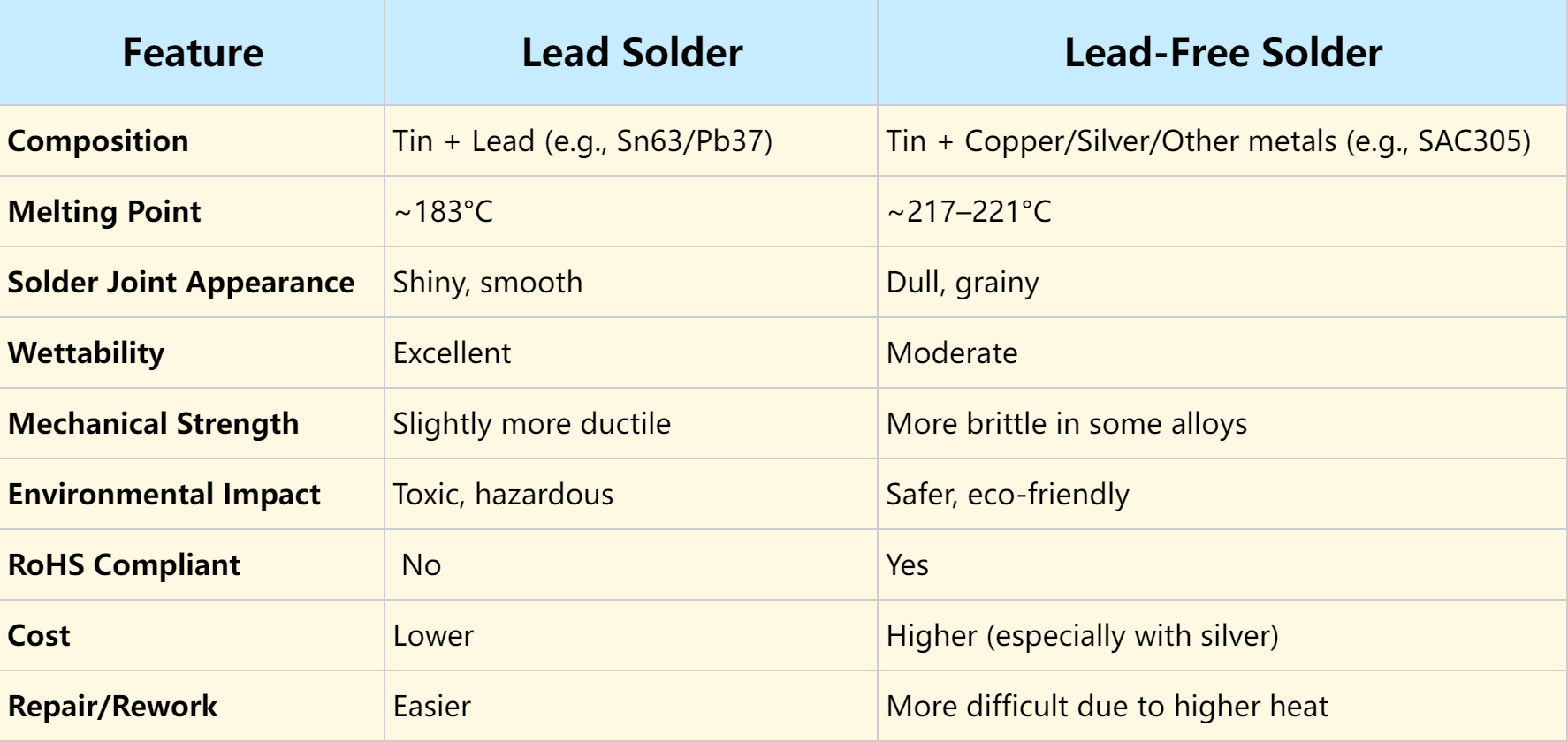

Comparing Lead-Free and Leaded Solder for Rework: Key Factors

To make an informed decision about which solder type to use for rework, consider the following factors. Each plays a crucial role in determining the success of your repair or modification.

1. Melting Temperature

As mentioned earlier, leaded solder melts at a lower temperature (around 183°C) compared to lead-free solder (217-220°C for SAC305). For rework, a lower melting point can be advantageous when working with heat-sensitive components, as it reduces the risk of thermal damage. However, modern soldering equipment, such as temperature-controlled soldering stations, can mitigate this issue with lead-free solder by maintaining precise heat levels.

2. Compatibility with Existing Solder

During rework, it’s critical to match the solder type used in the original assembly. Mixing leaded and lead-free solder can create weak or brittle joints due to differences in composition and melting behavior. If you’re unsure about the original solder, it’s often safer to use lead-free solder for newer boards (post-2006, after RoHS implementation) and leaded solder for older ones.

3. Ease of Use

Leaded solder is generally easier to handle during rework due to its better flow and lower melting point. This can be a significant advantage for beginners or when working on intricate repairs. Lead-free solder, on the other hand, requires more skill and patience, as it doesn’t wet as easily and may need higher heat settings.

4. Health and Environmental Impact

Lead-free solder is the clear winner when it comes to safety. Lead exposure from soldering fumes or improper handling can pose health risks over time, and leaded solder waste can harm the environment. Using lead-free solder aligns with global efforts to reduce hazardous substances in electronics.

5. Regulatory Compliance

If your rework project is for a commercial product or will be sold in regions with strict environmental regulations, lead-free solder is often mandatory. Compliance with standards like RoHS ensures that your work meets legal requirements and avoids potential penalties.

Practical Tips for Rework with Different Solder Types

Regardless of whether you choose lead-free or leaded solder, following best practices during rework can improve your results. Here are some actionable tips tailored to each solder type.

Reworking with Leaded Solder

- Use a soldering iron with a temperature setting around 300°C for desoldering and resoldering to avoid overheating components.

- Ensure proper ventilation and wear protective gear to minimize exposure to lead fumes.

- Use flux to improve wetting and flow, especially on older boards where oxidation may be present.

Reworking with Lead-Free Solder

- Set your soldering iron to a higher temperature, typically around 350°C, to accommodate the higher melting point of lead-free alloys.

- Be cautious with heat application to prevent damage to components or the board’s pads and traces.

- Consider using a preheater for larger boards to evenly distribute heat and reduce thermal stress during rework.

Common Solder Compositions for Rework: A Closer Look

Understanding specific solder compositions can help you select the right material for your rework needs. Below are some popular options for both leaded and lead-free categories, along with their properties.

Leaded Solder Compositions

- 63/37 (Sn63Pb37): This eutectic alloy offers the lowest melting point among leaded solders at 183°C, making it ideal for rework on delicate components.

- 60/40 (Sn60Pb40): Slightly less expensive than 63/37, this alloy melts over a small temperature range (183-190°C) and is suitable for general-purpose rework.

Lead-Free Solder Compositions

- SAC305 (Sn96.5Ag3.0Cu0.5): Widely used in modern electronics, this alloy melts at 217-220°C and provides strong, reliable joints for rework.

- Sn99.3Cu0.7: A cost-effective lead-free option with a melting point of 227°C, often used for less demanding rework tasks.

- SnBi (Tin-Bismuth): With a lower melting point of around 138°C, this alloy is suitable for rework on extremely heat-sensitive components, though it’s less common.

Conclusion: Making the Right Choice for Your Rework Project

Choosing between lead-free and leaded solder for rework depends on several factors, including the type of project, regulatory requirements, and personal skill level. Lead-free solder is often the go-to option for modern electronics due to its compliance with environmental standards and safer profile. However, leaded solder can still be valuable for specific rework tasks where its lower melting point and ease of use provide an advantage, provided its use is permitted.

By understanding the composition and characteristics of different solder types, you can select the best material for your rework needs. Whether you prioritize safety, performance, or compatibility, taking the time to match the solder to your project will ensure strong, reliable connections every time. Equip yourself with the right tools, follow best practices, and keep these considerations in mind to achieve professional-grade results in your rework endeavors.

ALLPCB

ALLPCB