Overview

With rapid advances in Internet of Things, artificial intelligence (AI), and sensor technologies, traditional safety helmets have evolved from simple head protection into intelligent devices: the AI smart safety helmet. By integrating head protection with real-time monitoring and alerts, these helmets enable a shift from passive protection to active prevention and intelligent control. They are used across construction, mining, power, and chemical industries to enhance industrial safety.

Five-layer Intelligent Protection System

The AI smart safety helmet integrates multiple sensors, AI algorithms, and communication modules to implement a five-layer intelligent protection system that improves safety and operational efficiency.

AI Core

The helmet includes an AI voice module supporting voice interaction and voice control, enabling hands-free operation and safer workflows. Optional AI workflow features can optimize task handling and improve work efficiency.

AI Visual Alert

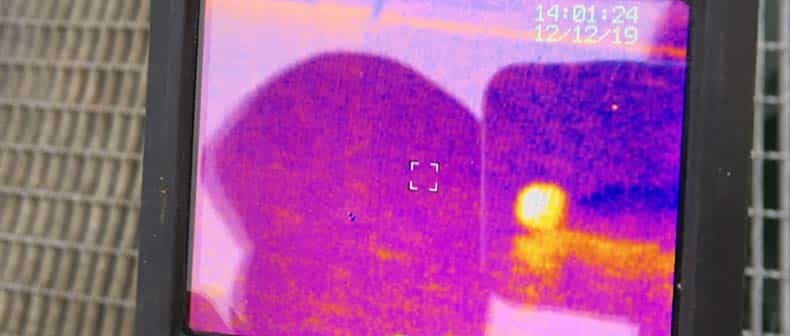

Using AI vision algorithms, the helmet can detect potential risks in the work area in real time, including falling objects, unsafe actions (for example, not wearing a helmet or smoking in prohibited areas), and entry into hazardous zones, and issue timely alerts.

AI Vital Signs Monitoring

Vital-sign sensors monitor the wearer’s heart rate, blood oxygen, and body temperature in real time. If anomalies occur, the system triggers an alert to buy time for emergency response.

AI Environmental Sensing

Integrated sensors detect environmental hazards such as toxic gases and high-voltage electrical fields, issuing audible and visual warnings to the wearer and notifying site managers.

AI Collaborative Defense

Sensors for fall detection, helmet removal, and temperature change build a dynamic safety field that continuously monitors the wearer’s status and ensures the helmet is being worn correctly.

Intelligent Management: Improving Efficiency and Coordination

Beyond basic protection, AI smart safety helmets provide intelligent management features that enhance coordination in hazardous work environments.

Real-time video transmission: Built-in high-resolution cameras (13 MP or 32 MP) can automatically upload footage when an alert is triggered or be manually transmitted by workers, allowing remote review of on-site conditions to verify compliance.

Two-way voice communication: Supports bidirectional voice between the platform and the helmet. Managers can remotely guide workers through issues, reducing the need for on-site intervention.

Photo and video capture: Workers can capture images or video to document equipment faults or hazards, generating incident reports uploaded to the platform for follow-up and remediation tracking.

Accurate positioning and track replay: The helmet supports multiple positioning technologies (GPS, BeiDou, RTK, UWB, Bluetooth, etc.) to report worker locations in real time. It can also record and replay movement tracks for up to 24 hours for accident investigation or process verification.

Geofence warnings: The platform can define restricted or warning zones. The helmet issues audible and visual alarms as a worker approaches a hazardous area and triggers platform notifications for manager intervention.

Proximity-to-live-line warning: By detecting the electric field strength of high-voltage lines, the helmet warns when a worker approaches a dangerous distance to prevent electric shock incidents.

Future Direction

As 5G and AI algorithms continue to advance, functionality will keep improving. Future developments will focus on more precise risk prediction, such as using historical data to estimate accident probabilities in specific areas for proactive prevention. Design will trend toward lighter weight to reduce wearer fatigue and extend device battery life.

The AI smart safety helmet represents a shift in industrial safety from passive protection to active warning and intelligent control. With ongoing innovation, these devices are expected to play an increasingly important role in safety management across more scenarios.

ALLPCB

ALLPCB