In the fast-paced world of electronics manufacturing, protecting printed circuit boards (PCBs) is crucial for ensuring durability and performance. One of the most innovative solutions today is the use of UV-curable eco-friendly PCB coatings. These coatings offer a perfect balance of speed, performance, and sustainability, making them a top choice for modern PCB protection. In this blog, we’ll dive deep into the UV curable conformal coating process, explore the benefits of eco-friendly UV coating for PCBs, and discuss the optimal UV curing parameters for PCB coatings to help you make informed decisions for your projects.

What Are UV-Curable Eco-Friendly PCB Coatings?

UV-curable coatings are specialized protective layers applied to PCBs that harden or "cure" when exposed to ultraviolet (UV) light. Unlike traditional coatings that rely on heat or air drying, UV-curable coatings offer rapid curing times—often within seconds. This speed enhances production efficiency without compromising on protection against moisture, dust, chemicals, and mechanical stress.

What sets eco-friendly UV coatings apart is their reduced environmental impact. These formulations are designed to minimize volatile organic compounds (VOCs), which are harmful emissions released during the curing process of conventional coatings. By opting for eco-friendly options, manufacturers can meet stricter environmental regulations while maintaining high-quality protection for electronic components.

Why Choose UV-Curable Coatings for PCBs?

The electronics industry demands solutions that keep up with tight production schedules and high-performance standards. UV-curable coatings deliver on both fronts. They provide:

- Fast Curing: Curing in seconds under UV light, compared to hours or days for traditional methods.

- Superior Protection: Resistance to environmental factors like humidity (up to 95% relative humidity) and temperature extremes (-40°C to 150°C).

- Sustainability: Lower energy consumption and reduced VOC emissions with eco-friendly formulations.

Understanding the UV Curable Conformal Coating Process

The UV curable conformal coating process is a streamlined method that ensures consistent and reliable protection for PCBs. Here’s a step-by-step breakdown of how it works:

- Preparation: The PCB surface is cleaned to remove dust, oils, and contaminants. A clean surface ensures proper adhesion of the coating.

- Application: The UV-curable coating, typically a liquid resin composed of monomers and photoinitiators, is applied to the PCB using methods like spraying, brushing, or dipping. Automated spraying systems can achieve uniform thickness, often between 25 to 75 micrometers, depending on the application.

- Curing: The coated PCB is exposed to UV light, usually in the wavelength range of 320-400 nanometers (nm). The light triggers a chemical reaction, polymerizing the coating and hardening it within 5 to 30 seconds.

- Inspection: Post-curing, the PCB is inspected for coverage and defects. Some UV coatings include fluorescent additives that glow under black light, making it easier to detect missed areas.

This process is not only fast but also highly controllable, allowing manufacturers to achieve consistent results even in high-volume production environments.

Benefits of Eco-Friendly UV Coating for PCBs

As environmental regulations tighten and companies prioritize sustainability, eco-friendly UV coating for PCBs has emerged as a game-changer. These coatings are formulated to reduce harmful emissions and energy use while maintaining the performance needed for reliable electronics. Let’s explore the key advantages:

Reduced Environmental Impact

Traditional solvent-based coatings release significant amounts of VOCs during curing, contributing to air pollution and health risks. Eco-friendly UV coatings, on the other hand, are often solvent-free or waterborne, cutting VOC emissions by up to 90%. Additionally, the UV curing process consumes less energy compared to heat-based curing, further lowering the carbon footprint.

Compliance with Regulations

Many industries must comply with strict environmental standards, such as the Restriction of Hazardous Substances (RoHS) directive and REACH regulations in Europe. Eco-friendly UV coatings are designed to meet these requirements, helping manufacturers avoid penalties and maintain market access.

Maintaining Performance Standards

Despite their green credentials, these coatings don’t compromise on protection. They offer excellent dielectric properties, with insulation resistance often exceeding 10^12 ohms, ensuring that sensitive electronic components remain safe from electrical shorts and interference.

Optimizing UV Curing Parameters for PCB Coatings

To achieve the best results with UV-curable coatings, it’s essential to fine-tune the UV curing parameters for PCB coatings. These parameters directly impact the coating’s performance, adhesion, and durability. Below are the critical factors to consider:

UV Light Intensity and Wavelength

The intensity of UV light, measured in milliwatts per square centimeter (mW/cm2), determines how quickly and thoroughly the coating cures. Most UV-curable coatings for PCBs require an intensity between 100 and 300 mW/cm2. The wavelength of the UV light is equally important, with 365 nm being a common standard for triggering the photoinitiators in the coating.

Exposure Time

Exposure time varies depending on the coating formulation and thickness. Typically, a curing time of 10 to 30 seconds is sufficient for a 50-micrometer-thick layer. Overexposure can lead to brittleness, while underexposure may result in incomplete curing and reduced protection.

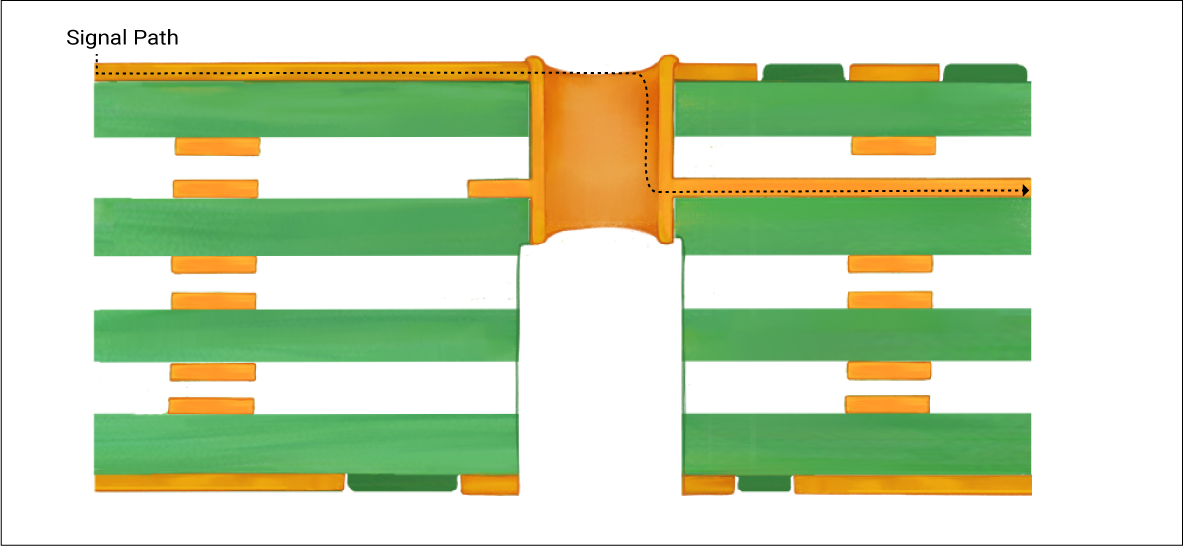

Coating Thickness

The thickness of the applied coating affects curing efficiency. Thicker layers (above 75 micrometers) may require higher UV intensity or longer exposure to ensure full curing through the entire depth. Manufacturers often use automated systems to maintain consistent thickness and avoid issues like shadowing, where components block UV light from reaching certain areas.

Environmental Conditions

Temperature and humidity in the curing environment can influence the process. For optimal results, maintain a temperature range of 20-25°C and relative humidity below 60%. High humidity can interfere with adhesion, while extreme temperatures may affect the coating’s viscosity during application.

By carefully controlling these parameters, manufacturers can ensure that the coating achieves maximum hardness, adhesion, and resistance to environmental stressors.

Challenges and Solutions in UV-Curable PCB Coatings

While UV-curable coatings offer numerous benefits, there are challenges to consider during implementation. Understanding these obstacles and their solutions can help ensure successful adoption in your production process.

Shadowing Effect

In complex PCB designs with tall components, UV light may not reach all areas, leaving some parts of the coating uncured. To address this, many eco-friendly UV coatings include a secondary curing mechanism, such as moisture or heat, to harden shadowed areas over time.

Equipment Costs

UV curing systems require an initial investment in specialized lamps and conveyors. However, the long-term savings from faster production cycles and reduced energy use often offset these costs. For smaller operations, portable UV curing units are a cost-effective alternative.

Material Compatibility

Not all PCB materials or components are compatible with UV coatings. For instance, some sensitive components may degrade under UV exposure. Testing the coating on a sample board before full-scale application can prevent potential issues.

How UV-Curable Coatings Enhance Production Efficiency

One of the standout features of UV-curable coatings is their ability to streamline manufacturing processes. Traditional coatings often require long drying times, slowing down production and increasing the risk of contamination during the waiting period. In contrast, UV coatings cure almost instantly, allowing PCBs to move to the next stage of assembly within minutes.

This speed translates to higher throughput. For example, a production line using UV-curable coatings can process up to 500 boards per hour, compared to just 100 with heat-cured coatings. This efficiency is especially valuable in industries like automotive and consumer electronics, where time-to-market is critical.

Future Trends in UV-Curable Eco-Friendly Coatings

The demand for sustainable and efficient manufacturing solutions is driving innovation in UV-curable coatings. Recent advancements point to exciting possibilities for the future:

- Bio-Based Formulations: Researchers are developing UV coatings derived from renewable resources, further reducing environmental impact.

- Enhanced Durability: New formulations aim to improve resistance to harsher conditions, such as prolonged exposure to temperatures above 150°C.

- Smart Coatings: Emerging technologies may enable coatings with self-healing properties or indicators that signal when protection is compromised.

These trends highlight the potential for UV-curable coatings to remain at the forefront of PCB protection, balancing performance with environmental responsibility.

Conclusion: A Sustainable Future with UV-Curable PCB Coatings

UV-curable eco-friendly PCB coatings represent a significant step forward in electronics manufacturing. By combining the speed of the UV curable conformal coating process, the environmental benefits of eco-friendly UV coating for PCBs, and the precision of optimized UV curing parameters for PCB coatings, these solutions offer a compelling choice for protecting electronic components.

Whether you’re looking to boost production efficiency, meet environmental standards, or ensure the longevity of your PCBs, UV-curable coatings deliver on all fronts. As technology continues to evolve, adopting these innovative materials can position your operations for success in a competitive and sustainability-focused market.

ALLPCB

ALLPCB