When designing access control systems, every component of a printed circuit board (PCB) plays a critical role in ensuring reliability and performance. One often overlooked but vital factor is the PCB surface finish. The type of finish you choose—whether it's ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling)—directly affects corrosion resistance, solderability of components, and the overall durability of the system. In this comprehensive guide, we’ll explore how PCB surface finish impacts access control system performance, compare ENIG vs HASL in this context, and provide actionable insights for selecting the right circuit board finish.

Why PCB Surface Finish Matters for Access Control Systems

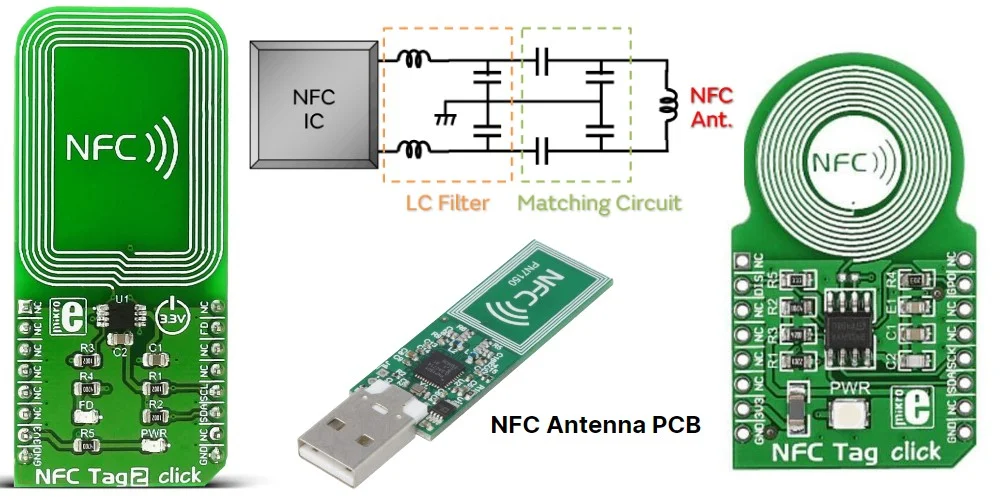

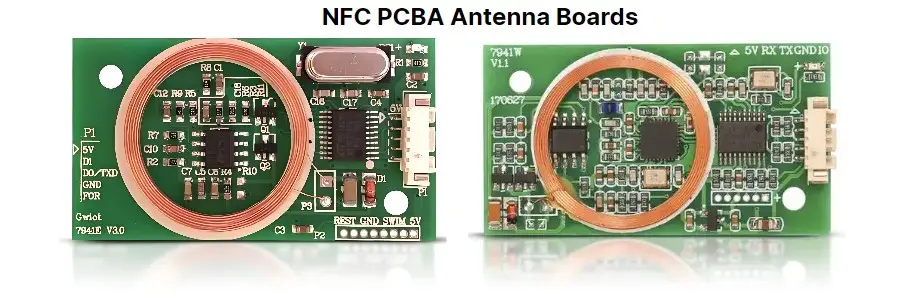

Access control systems, such as keycard readers, biometric scanners, and electronic locks, rely on PCBs to process signals, manage data, and ensure secure communication. These systems often operate in diverse environments—indoors, outdoors, or even in harsh conditions with high humidity or temperature fluctuations. The PCB surface finish serves as a protective layer for the copper traces on the board, preventing oxidation, ensuring reliable soldering of components, and maintaining signal integrity over time.

A poorly chosen finish can lead to issues like corrosion, weak solder joints, or signal degradation, which could compromise the performance of an access control system. For instance, corrosion on a PCB can increase resistance in critical circuits, potentially causing delays in response times or even system failures. With this in mind, let's dive into the key aspects of how surface finishes influence performance and longevity.

Key Factors of PCB Surface Finish in Access Control Systems

1. Corrosion Resistance for Long-Term Reliability

PCB corrosion resistance is a top priority for access control systems, especially those installed in outdoor or humid environments. Corrosion occurs when exposed copper on a PCB reacts with moisture, oxygen, or pollutants, forming oxides that degrade electrical conductivity. A high-quality surface finish acts as a barrier, protecting the copper and ensuring the system remains functional over years of use.

For example, in coastal areas where salt air accelerates corrosion, a finish with superior protective properties can prevent failures in access control devices. Without adequate PCB corrosion resistance, systems may experience intermittent faults or complete breakdowns, leading to security vulnerabilities.

2. Solderability of Components for Strong Connections

The solderability of components on a PCB is another critical factor influenced by the surface finish. Access control systems often include microcontrollers, sensors, and communication modules that must be securely soldered to the board. A finish that promotes good solderability ensures strong, reliable connections, reducing the risk of cold solder joints or component detachment during operation or thermal cycling.

Poor solderability can lead to higher defect rates during manufacturing and reduced performance in the field. For instance, uneven solder distribution might cause intermittent connections in a biometric scanner, leading to inaccurate readings or system downtime.

3. Signal Integrity and Electrical Performance

Access control systems rely on precise signal transmission for tasks like reading RFID cards or processing fingerprint data. The surface finish can impact signal integrity by affecting the impedance of traces and the quality of electrical connections. A finish that introduces irregularities or degradation over time can lead to signal loss or noise, which might delay response times or cause errors in authentication.

For high-frequency applications, such as wireless access control systems operating at 2.4 GHz, a smooth and consistent surface finish is essential to minimize signal attenuation. Choosing the right circuit board finish ensures that electrical performance remains stable, even under demanding conditions.

ENIG vs HASL: Comparing Surface Finishes for Access Control Systems

When it comes to selecting a circuit board finish for access control systems, two popular options stand out: ENIG and HASL. Both have unique advantages and trade-offs, especially in terms of PCB corrosion resistance, solderability of components, and overall performance. Let's break down the ENIG vs HASL access control comparison to help you make an informed decision.

What is ENIG (Electroless Nickel Immersion Gold)?

ENIG is a two-layer finish consisting of a nickel base layer topped with a thin layer of gold. The nickel provides a robust barrier against corrosion, while the gold ensures excellent solderability and surface flatness. This finish is widely used in applications requiring high reliability and precision.

Advantages of ENIG for Access Control Systems

- Superior Corrosion Resistance: The nickel layer in ENIG offers excellent protection against oxidation, making it ideal for access control systems in humid or outdoor environments. Studies suggest that ENIG-finished PCBs can withstand over 1000 hours of salt spray testing without significant degradation.

- Excellent Solderability: The gold layer ensures consistent and reliable soldering, even for fine-pitch components commonly found in modern access control devices.

- Flat Surface for Precision: ENIG provides a uniform, flat surface, which is critical for maintaining signal integrity in high-frequency circuits. This can reduce impedance mismatches by up to 5-10% compared to uneven finishes.

- Long Shelf Life: ENIG-finished boards can be stored for extended periods (up to 12 months) without tarnishing, ensuring reliability during manufacturing delays.

Disadvantages of ENIG

- Higher Cost: ENIG is more expensive than other finishes, which may impact budget-conscious projects. The cost can be 20-30% higher than alternatives like HASL.

- Potential for Black Pad: If not applied correctly, ENIG can develop "black pad" issues, where the nickel layer corrodes, leading to poor solder joints. However, this is rare with proper manufacturing controls.

What is HASL (Hot Air Solder Leveling)?

HASL involves dipping the PCB in molten solder and then using hot air to remove excess material, leaving a thin layer of solder on the copper. It’s one of the most common and cost-effective finishes available, often used in less demanding applications.

Advantages of HASL for Access Control Systems

- Cost-Effective: HASL is significantly cheaper than ENIG, making it a popular choice for budget-sensitive access control projects. Costs can be 50-60% lower than premium finishes.

- Good Solderability: The solder coating provides a ready-to-use surface for component attachment, ensuring decent reliability for standard applications.

- Widely Available: HASL is a well-established process supported by most PCB manufacturers, reducing lead times for production.

Disadvantages of HASL

- Limited Corrosion Resistance: HASL offers less protection against oxidation compared to ENIG. In humid or harsh environments, corrosion can set in within 6-12 months, leading to potential failures in access control systems.

- Uneven Surface: The hot air leveling process can result in an uneven finish, which may cause issues with fine-pitch components or high-frequency signals. Impedance variations can be as high as 15% in some cases.

- Thermal Stress: The high temperatures used in HASL can introduce thermal stress to the PCB, potentially affecting delicate access control circuits.

Circuit Board Finish Selection Criteria for Access Control Systems

Choosing the right circuit board finish depends on the specific requirements of your access control system. Here are the key criteria to consider when making your decision:

1. Environmental Conditions

If your access control system will be exposed to harsh conditions like high humidity, temperature extremes, or salty air, prioritize a finish with strong PCB corrosion resistance. ENIG is often the better choice in such scenarios due to its robust protective layers. For indoor systems in controlled environments, HASL may suffice and save on costs.

2. Component Complexity

Modern access control systems often use fine-pitch components and surface-mount technology (SMT). A flat and uniform finish like ENIG ensures better solderability of components and reduces the risk of defects. HASL may struggle with tiny components due to its uneven surface.

3. Signal Requirements

For systems with high-frequency signals or strict impedance control, such as wireless access control devices, ENIG’s smooth finish helps maintain signal integrity. HASL’s inconsistencies can introduce noise or signal loss, impacting performance.

4. Budget Constraints

If cost is a major concern and the system will operate in a benign environment, HASL offers a reliable, affordable option. However, for mission-critical access control applications where failure is not an option, investing in ENIG may provide better long-term value despite the higher upfront cost.

5. Manufacturing and Assembly Needs

Consider the manufacturing process and timeline. ENIG has a longer shelf life, making it suitable for projects with potential delays. HASL, while quicker to produce, may require faster assembly to avoid oxidation of the solder layer.

Practical Tips for Optimizing PCB Surface Finish in Access Control Systems

Beyond choosing between ENIG and HASL, here are some additional strategies to maximize the performance of your access control system through effective PCB surface finish practices:

- Work with Reliable Manufacturers: Ensure your PCB supplier follows strict quality control standards to avoid issues like uneven coatings or black pad defects with ENIG.

- Test for Environmental Durability: Conduct environmental stress tests, such as humidity or salt spray testing, to validate the PCB corrosion resistance of your chosen finish.

- Consider Hybrid Finishes: For complex systems, explore hybrid finishes that combine the benefits of multiple coatings, tailored to specific areas of the PCB.

- Optimize Design for Solderability: Design your PCB layout to minimize thermal stress during soldering, enhancing the solderability of components regardless of the finish.

- Plan for Longevity: Factor in the expected lifespan of your access control system and choose a finish that supports long-term reliability without frequent maintenance.

Conclusion: Making the Right Choice for Access Control Performance

The PCB surface finish plays a pivotal role in the performance, reliability, and longevity of access control systems. Whether you opt for ENIG or HASL, understanding the trade-offs in terms of PCB corrosion resistance, solderability of components, and signal integrity is essential. ENIG stands out for its superior protection and precision, making it ideal for demanding environments and high-performance systems. On the other hand, HASL offers a cost-effective solution for simpler, indoor applications where conditions are less challenging.

By carefully evaluating the circuit board finish selection criteria—such as environmental exposure, component needs, and budget—you can ensure your access control system operates flawlessly for years to come. A well-chosen surface finish not only enhances performance but also safeguards security, a critical factor in access control technology.

ALLPCB

ALLPCB