When it comes to designing printed circuit boards (PCBs) for defibrillators, selecting the right substrate material is crucial. The substrate directly impacts the device's performance, reliability, and safety in life-saving medical applications. So, what are the best PCB substrate materials for defibrillators? Key options include FR-4 for its cost-effectiveness and durability, high-frequency laminates like Rogers for superior signal integrity, and materials with high thermal conductivity for heat dissipation. Factors such as dielectric constant, flame retardancy, and thermal performance also play a significant role.

In this detailed guide, we’ll explore why substrate selection matters for defibrillator PCBs and break down the essential properties to consider. From high-frequency PCB materials to flame retardant PCB materials, we’ll cover everything you need to know to make an informed choice for your next project.

Why Substrate Materials Are Critical for Defibrillator PCBs

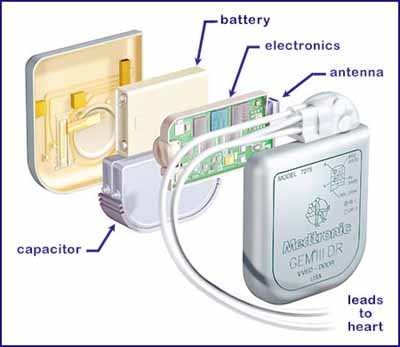

Defibrillators are medical devices designed to deliver controlled electric shocks to restore normal heart rhythms during cardiac emergencies. The PCBs inside these devices must operate under high-stress conditions, handling rapid signal transmission, high voltages, and potential heat buildup. A poorly chosen substrate can lead to signal loss, overheating, or even device failure—outcomes that are unacceptable in life-critical applications.

The substrate material forms the foundation of a PCB, providing mechanical support and electrical insulation between conductive layers. Its properties, such as dielectric constant, thermal conductivity, and flame resistance, directly affect the board’s performance. For defibrillators, the substrate must ensure reliable operation, minimize signal interference, and meet strict safety standards. Let’s dive into the specific material properties that matter most.

Key Properties of PCB Substrate Materials for Defibrillators

Not all substrates are created equal. When selecting materials for defibrillator PCBs, engineers must evaluate several critical properties to ensure optimal performance. Below, we’ll explore these factors in detail, focusing on their relevance to medical applications.

1. Dielectric Constant and Signal Integrity with High-Frequency PCB Materials

The dielectric constant (Dk) of a substrate measures its ability to store electrical energy in an electric field. For defibrillator PCBs, which often operate at high frequencies to process rapid signals, a low and stable dielectric constant is essential. A high Dk can cause signal delays or distortion, which could compromise the device’s response time.

For high-frequency applications, materials like PTFE-based laminates or specialized high-frequency PCB materials are often preferred. These materials typically have a dielectric constant ranging from 2.2 to 3.5, compared to standard FR-4, which has a Dk of around 4.3 to 4.7 at 1 MHz. This lower Dk ensures better signal integrity, reducing the risk of errors in critical operations. For example, in a defibrillator’s control circuit, maintaining signal accuracy during a high-voltage pulse is non-negotiable.

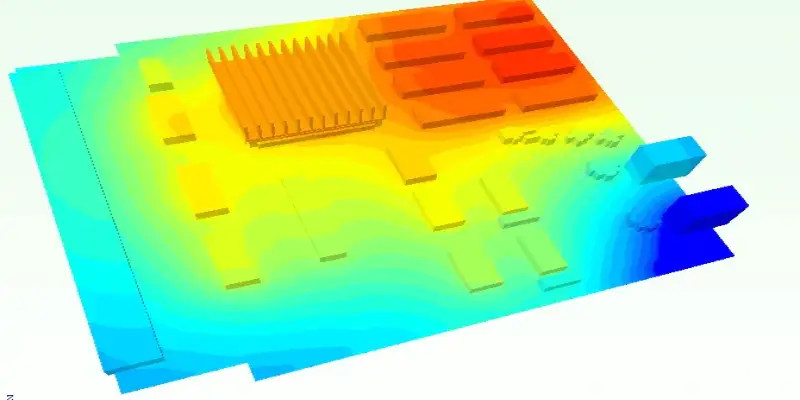

2. Thermal Performance for Heat Dissipation

Defibrillators generate significant heat during operation, especially when delivering high-energy shocks. Poor heat dissipation can damage components or degrade performance over time. That’s why thermal performance PCB materials are a top consideration.

Substrates with high thermal conductivity, such as aluminum-backed materials or ceramics, can effectively transfer heat away from critical components. For instance, aluminum substrates offer thermal conductivity values of 1-2 W/m·K, far surpassing FR-4’s typical 0.3 W/m·K. In a defibrillator, this can prevent overheating of power components during repeated use, extending the device’s lifespan and reliability.

3. Flame Retardancy for Safety

Safety is paramount in medical devices, and flame retardant PCB materials are a must for defibrillator designs. These materials are engineered to resist ignition and slow the spread of fire in case of a short circuit or electrical fault. Most substrates used in medical applications comply with UL 94 V-0 standards, which require the material to self-extinguish within 10 seconds after exposure to a flame.

FR-4, a common flame-retardant substrate made from woven fiberglass and epoxy resin, meets this standard and is widely used in medical PCBs. However, for applications requiring even higher safety margins, halogen-free materials are gaining popularity due to their reduced toxicity in the event of combustion. Ensuring flame retardancy not only protects the device but also aligns with stringent medical safety regulations.

4. Mechanical Strength and Durability

Defibrillators are often portable devices used in emergency settings, meaning their internal PCBs must withstand physical stress, vibrations, and potential impacts. The substrate material needs to provide mechanical stability to prevent cracks or delamination over time.

Standard FR-4 offers good mechanical strength with a tensile strength of around 310 MPa, making it suitable for most applications. For more demanding environments, polyimide substrates provide superior flexibility and durability, withstanding temperatures up to 260°C without deforming. Choosing a mechanically robust material ensures the PCB can endure the rigors of real-world use without compromising performance.

Popular PCB Substrate Materials for Defibrillators

With the key properties in mind, let’s look at some of the most commonly used PCB substrate materials for defibrillators. Each material has unique strengths, making it suitable for specific aspects of defibrillator design.

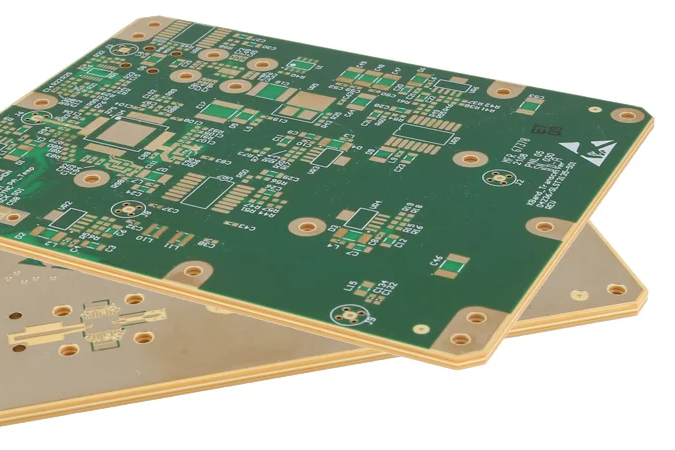

FR-4: The Cost-Effective Standard

FR-4 is the most widely used PCB substrate material across industries, including medical applications. Made from fiberglass cloth and epoxy resin, it offers a balance of cost, performance, and flame retardancy (UL 94 V-0 rated). Its dielectric constant of 4.3-4.7 works well for low- to mid-frequency circuits in defibrillators, though it may not be ideal for high-frequency signal paths due to higher signal loss.

FR-4’s thermal conductivity is relatively low at 0.3 W/m·K, so it’s often paired with heat sinks or thermal vias in high-power sections of a defibrillator PCB. Its affordability and availability make it a go-to choice for non-critical or budget-conscious designs.

High-Frequency Laminates for Signal Precision

For defibrillator circuits requiring rapid signal processing, high-frequency PCB materials like PTFE-based laminates or ceramic-filled composites are ideal. These materials offer low dielectric constants (2.2-3.5) and low dissipation factors (0.001-0.002), minimizing signal loss and ensuring accurate timing during operation.

While these materials are more expensive than FR-4, their performance in high-frequency applications justifies the cost. They are often used in the signal control and monitoring sections of defibrillator PCBs, where precision is critical.

Polyimide for High-Temperature Environments

Polyimide substrates are known for their excellent thermal stability, withstanding temperatures up to 260°C without degrading. This makes them suitable for defibrillator PCBs that may experience extreme heat during operation or sterilization processes. Polyimide also offers flexibility, which is beneficial for compact or foldable designs in portable defibrillators.

While polyimide has a higher dielectric constant (around 3.5-4.0) compared to high-frequency materials, its durability and heat resistance make it a strong candidate for specific applications within medical devices.

Aluminum and Ceramic Substrates for Thermal Management

For power delivery circuits in defibrillators, where heat dissipation is a major concern, aluminum and ceramic substrates shine. Aluminum-backed PCBs provide thermal conductivity of 1-2 W/m·K, effectively managing heat from high-power components. Ceramics, such as alumina, offer even higher thermal conductivity (20-30 W/m·K) and excellent electrical insulation, though they are more brittle and costly.

These thermal performance PCB materials are often used in hybrid designs, where different sections of the PCB require distinct substrates to optimize performance. For instance, an aluminum substrate might be used near the power output stage of a defibrillator, while FR-4 handles less heat-intensive areas.

How to Choose the Right Substrate for Your Defibrillator PCB

Selecting the ideal substrate involves balancing performance requirements, cost, and regulatory compliance. Here are some practical steps to guide your decision:

- Identify Circuit Requirements: Determine if your design prioritizes high-frequency signal integrity, thermal management, or mechanical durability. For high-frequency needs, opt for low-Dk materials; for heat dissipation, choose aluminum or ceramics.

- Consider Safety Standards: Ensure the material meets medical safety requirements, such as UL 94 V-0 flame retardancy and biocompatibility if the PCB may come into indirect contact with patients.

- Evaluate Cost vs. Performance: While high-performance materials like ceramics offer superior properties, they can significantly increase production costs. Use hybrid designs to combine cost-effective and premium substrates where needed.

- Test Under Real Conditions: Simulate the operating environment of the defibrillator to assess how the substrate performs under stress, heat, and electrical loads.

By carefully analyzing these factors, you can select a substrate that ensures reliability without overspending on unnecessary features.

Challenges in Substrate Selection for Medical PCBs

While the options for PCB substrate materials for defibrillators are diverse, engineers face several challenges during selection. Miniaturization is a common trend in medical devices, requiring substrates that support high-density interconnects without sacrificing performance. Additionally, regulatory compliance, such as meeting ISO 13485 standards for medical devices, adds complexity to material choices.

Another challenge is balancing dielectric constant PCB materials with other properties. A low Dk is ideal for signal integrity but may come with trade-offs in mechanical strength or cost. Working with experienced PCB manufacturers can help navigate these challenges by providing access to advanced materials and design expertise. ."

."

Future Trends in PCB Substrates for Medical Devices

As medical technology advances, so do the materials used in PCB substrates. Emerging trends include the development of bio-compatible and eco-friendly substrates that reduce environmental impact without compromising performance. Additionally, advancements in nanotechnology are leading to substrates with enhanced thermal and electrical properties, potentially revolutionizing defibrillator designs.

Flexible and stretchable substrates are also gaining traction, enabling wearable or implantable defibrillator technologies. These innovations highlight the importance of staying updated on material advancements to remain competitive in the medical device industry.

Conclusion: Making an Informed Choice for Defibrillator PCBs

Selecting the right substrate for defibrillator PCBs is a decision that impacts performance, safety, and cost. By focusing on key properties like dielectric constant, thermal conductivity, and flame retardancy, you can ensure your design meets the demands of life-saving applications. Whether you choose FR-4 for its affordability, high-frequency PCB materials for signal precision, or thermal performance PCB materials for heat management, understanding your project’s unique needs is the first step.

At ALLPCB, we’re committed to supporting engineers in creating reliable, high-quality PCBs for medical applications. With a range of substrate options and expert guidance, we can help you bring your defibrillator designs to life with confidence. Remember, material matters—and the right choice can make all the difference in critical moments.

ALLPCB

ALLPCB