In the rapidly evolving field of quantum computing, the demand for high-performance printed circuit boards (PCBs) has never been greater. Quantum computing PCBs require specialized materials to handle extreme conditions like cryogenic temperatures and to ensure low signal loss for precise data transmission. This guide dives deep into the world of advanced materials for quantum computing PCBs, focusing on quantum PCB substrate materials, high-performance PCB materials, cryogenic PCB substrates, low-loss PCB materials, and PTFE PCB quantum applications. Whether you're an engineer or a tech enthusiast, this comprehensive resource will help you understand the critical role of materials in quantum computing hardware.

At its core, the choice of PCB materials for quantum computing revolves around performance under extreme conditions and maintaining signal integrity. In this blog, we'll explore the unique challenges of designing PCBs for quantum systems, the best materials for these applications, and how they contribute to the success of quantum technologies.

Why Material Choice Matters in Quantum Computing PCBs

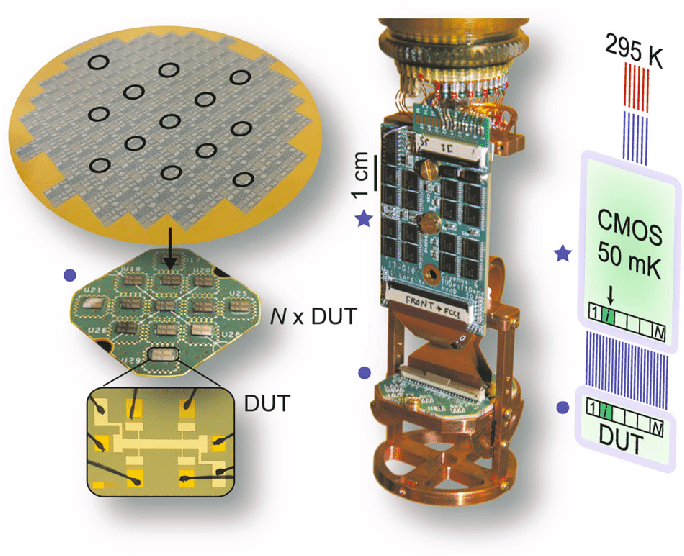

Quantum computing operates on principles vastly different from classical computing. Quantum bits, or qubits, are highly sensitive to environmental factors like temperature, electromagnetic interference, and signal loss. PCBs used in quantum systems often need to function at cryogenic temperatures—sometimes as low as a few millikelvins above absolute zero (-273°C or -459°F)—to minimize thermal noise and maintain qubit coherence.

Traditional PCB materials like FR-4, commonly used in everyday electronics, fall short in these extreme conditions. They lack the thermal stability and low-loss properties needed for quantum applications. This is where advanced materials come into play, offering solutions for thermal management, signal integrity, and durability in harsh environments.

Key Challenges in Quantum PCB Design

Before diving into specific materials, let's look at the unique challenges that quantum PCB design presents. These challenges dictate the need for specialized quantum PCB substrate materials and high-performance PCB materials.

- Cryogenic Temperatures: Quantum systems often operate in dilution refrigerators at temperatures below 1 Kelvin. Materials must withstand thermal contraction and maintain mechanical stability without cracking or warping.

- Low Signal Loss: Qubits require precise control and readout signals. Any signal loss or interference can disrupt quantum states, making low-loss PCB materials essential.

- High-Frequency Performance: Quantum control signals often operate at microwave frequencies (4-8 GHz). Materials must support these frequencies with minimal dielectric loss.

- Electromagnetic Shielding: Qubits are highly sensitive to external noise. PCB materials need to minimize electromagnetic interference (EMI) to protect quantum coherence.

Addressing these challenges requires a deep understanding of material properties and their behavior under extreme conditions. Let’s explore the materials that meet these stringent requirements.

Top Advanced Materials for Quantum Computing PCBs

The following materials are at the forefront of high-performance PCB materials for quantum computing. Each offers unique properties tailored to the demands of quantum systems.

1. Polytetrafluoroethylene (PTFE) for Quantum PCBs

Polytetrafluoroethylene, commonly known as PTFE, is a popular choice for PTFE PCB quantum applications due to its excellent electrical properties. PTFE-based laminates are widely used in high-frequency and low-loss applications.

- Low Dielectric Constant: PTFE has a dielectric constant of around 2.1, which minimizes signal delay and ensures high-speed transmission of microwave signals critical for quantum control.

- Low Loss Tangent: With a loss tangent as low as 0.0002 at 10 GHz, PTFE is one of the best low-loss PCB materials, reducing signal attenuation.

- Thermal Stability: PTFE remains stable at cryogenic temperatures, making it suitable for cryogenic PCB substrates.

PTFE laminates are often reinforced with woven glass or ceramic fillers to enhance mechanical strength while maintaining their electrical advantages. These properties make PTFE a top contender for quantum computing PCBs where precision and minimal interference are paramount.

Suggested Image Placement: Place an image here showing a close-up of a PTFE-based PCB with annotations highlighting its layers. ALT Text: "PTFE-based PCB for quantum computing with low-loss properties."

2. Rogers Corporation Laminates for High-Performance

Specialty laminates designed for high-frequency applications are another excellent option for high-performance PCB materials. These laminates are engineered to provide consistent performance at microwave frequencies and low temperatures.

- Dielectric Performance: These materials offer dielectric constants ranging from 2.2 to 10.2, allowing engineers to select the best match for specific quantum control frequencies.

- Thermal Conductivity: Some variants are designed with enhanced thermal conductivity to manage heat dissipation even at cryogenic levels.

- Low Loss: With loss tangents as low as 0.0009 at 10 GHz, they rank among the best low-loss PCB materials for quantum applications.

These laminates are often used in quantum systems for RF and microwave signal routing, ensuring minimal signal distortion and high reliability.

3. Polyimide for Cryogenic Stability

Polyimide is a high-performance polymer often used in cryogenic PCB substrates due to its exceptional thermal and mechanical stability. It can withstand extreme temperature swings without degrading.

- Temperature Range: Polyimide remains flexible and durable from -269°C to over 400°C, making it ideal for quantum systems operating in dilution refrigerators.

- Mechanical Strength: It resists cracking and warping, even under thermal stress caused by rapid cooling.

- Electrical Insulation: Polyimide provides excellent insulation, reducing the risk of short circuits in densely packed quantum circuits.

While polyimide may not match PTFE in terms of low-loss performance, it is often used in hybrid designs where thermal stability is a priority over high-frequency performance.

4. Ceramic Substrates for Thermal and Electrical Performance

Ceramic substrates, such as alumina and aluminum nitride, are gaining traction in quantum PCB design due to their unique combination of thermal and electrical properties.

- High Thermal Conductivity: Aluminum nitride, for instance, has a thermal conductivity of up to 170 W/m·K, far surpassing traditional materials like FR-4 (0.3 W/m·K). This helps manage heat even in cryogenic setups.

- Dielectric Strength: Ceramics offer high dielectric strength, preventing electrical breakdown in high-voltage quantum control circuits.

- Stability at Low Temperatures: Ceramics maintain structural integrity at millikelvin temperatures, making them suitable for cryogenic PCB substrates.

Ceramic substrates are often used in applications where thermal management and electrical isolation are critical, though their higher cost can be a limiting factor for large-scale production.

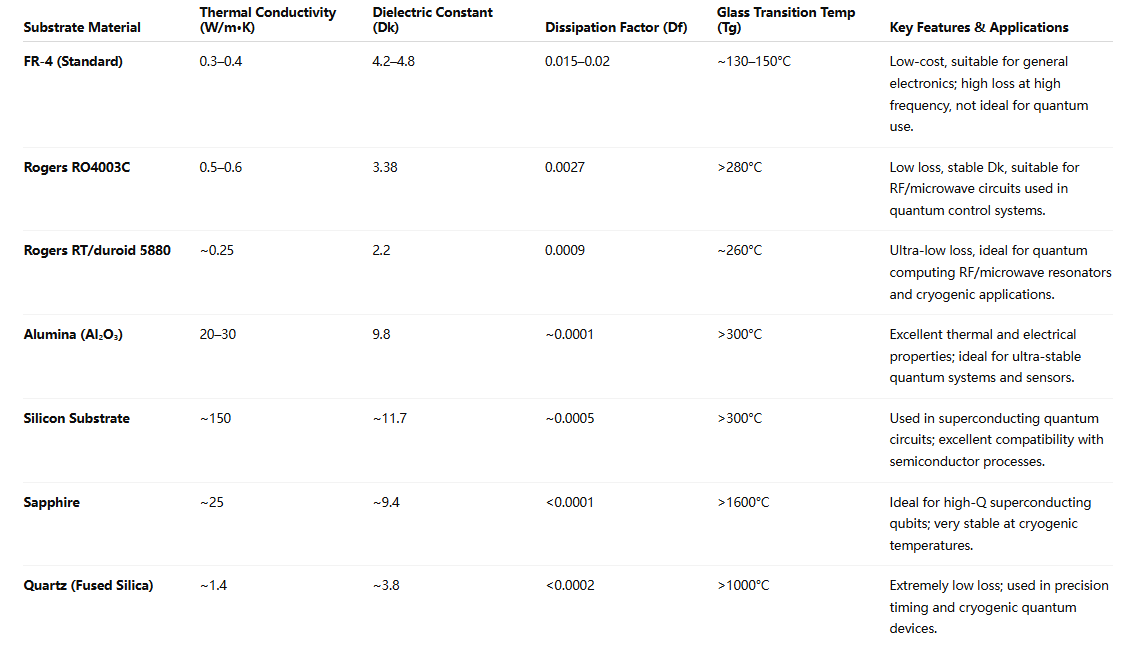

Comparing Material Properties for Quantum PCBs

To help engineers choose the right quantum PCB substrate materials, let’s compare the key properties of the materials discussed above. The table below provides a quick reference for dielectric constant, loss tangent, and thermal stability—crucial factors in quantum computing PCB design.

| Material | Dielectric Constant (at 10 GHz) | Loss Tangent (at 10 GHz) | Thermal Stability |

|---|---|---|---|

| PTFE | 2.1 | 0.0002 | Stable at cryogenic temperatures |

| Specialty Laminates | 2.2 - 10.2 | 0.0009 | Good at low temperatures |

| Polyimide | 3.5 | 0.008 | Excellent (-269°C to 400°C) |

| Ceramics (Aluminum Nitride) | 8.5 | 0.001 | Excellent at millikelvin levels |

This comparison highlights why materials like PTFE are preferred for low-loss PCB materials in high-frequency quantum applications, while polyimide and ceramics excel in cryogenic PCB substrates for thermal stability.

Practical Applications of Advanced Materials in Quantum Computing

Advanced materials are not just theoretical solutions; they are actively shaping the future of quantum computing. Here are some real-world applications where these high-performance PCB materials make a difference:

- Qubit Control and Readout: PTFE-based PCBs are used to route microwave signals for controlling and reading qubit states with minimal loss. Their low dielectric constant ensures signal speeds remain high, critical for maintaining quantum coherence times.

- Cryogenic Environments: Polyimide and ceramic substrates are integral in dilution refrigerators, providing the mechanical and thermal stability needed to house quantum chips at temperatures below 1 Kelvin.

- Hybrid Quantum Systems: Combining different materials, such as PTFE for signal layers and ceramics for thermal management, allows for hybrid PCB designs that balance multiple performance criteria.

How to Select the Right Material for Your Quantum PCB

Choosing the right material for a quantum computing PCB depends on the specific requirements of your project. Here are some factors to consider when selecting quantum PCB substrate materials:

- Operating Frequency: For high-frequency microwave signals, prioritize low-loss PCB materials like PTFE with a low loss tangent.

- Temperature Range: If your system operates at millikelvin temperatures, opt for cryogenic PCB substrates like polyimide or ceramics that can handle extreme cold without degrading.

- Budget Constraints: While ceramics offer superior thermal performance, they are more expensive than PTFE or polyimide. Balance performance with cost for large-scale production.

- Signal Integrity Needs: Ensure the material’s dielectric properties match the impedance requirements of your quantum control circuits (typically 50 ohms for RF lines).

By carefully evaluating these factors, you can select a material that optimizes performance for your specific quantum computing application.

Future Trends in Quantum PCB Materials

The field of quantum computing is advancing rapidly, and so is the development of PCB materials. Researchers are exploring new composites and nanotechnology to create substrates with even lower loss tangents and higher thermal conductivity. Innovations like graphene-based materials and metamaterials hold promise for reducing signal loss to near-zero levels, potentially revolutionizing PTFE PCB quantum designs.

Additionally, sustainable and recyclable materials are gaining attention as the industry seeks to reduce the environmental impact of PCB manufacturing. These advancements could lead to more cost-effective and eco-friendly solutions for quantum computing hardware in the coming years.

Conclusion: Building the Future of Quantum Computing with Advanced Materials

The success of quantum computing hinges on the ability to design PCBs that can operate under extreme conditions while maintaining unparalleled precision. Materials like PTFE, specialty laminates, polyimide, and ceramics are paving the way for high-performance PCB materials tailored to the unique demands of quantum systems. Whether you’re focused on low-loss PCB materials for signal integrity or cryogenic PCB substrates for thermal stability, understanding these advanced materials is key to unlocking the full potential of quantum technologies.

At ALLPCB, we are committed to supporting engineers and innovators in navigating the complexities of quantum PCB design. By leveraging the right quantum PCB substrate materials, you can build reliable, efficient, and cutting-edge solutions for the future of computing.

ALLPCB

ALLPCB