Are you struggling to achieve flawless SMT joints in your PCB assembly process? Reflow soldering is the key to success, but mastering it requires understanding critical aspects like the SMT reflow soldering profile, reflow oven temperature settings, and more. In this comprehensive guide, we’ll uncover the secrets to perfect reflow soldering by diving deep into process optimization, defect causes, and equipment maintenance. Whether you're a seasoned engineer or just starting with surface mount technology (SMT), this blog will equip you with actionable tips to elevate your soldering game.

What Is Reflow Soldering and Why Does It Matter for SMT?

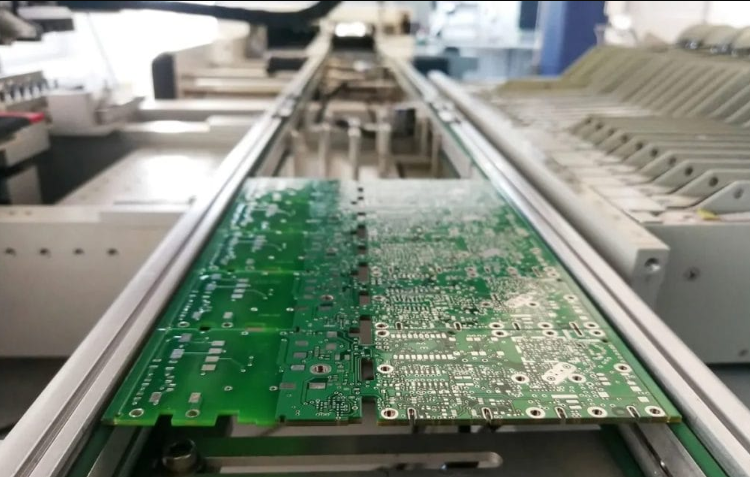

Reflow soldering is the most widely used method for attaching surface mount components to printed circuit boards (PCBs). This process involves applying solder paste to the PCB, placing components, and then heating the assembly in a reflow oven to melt the solder, creating strong and reliable joints. It’s a cornerstone of modern electronics manufacturing, especially as devices become smaller and more complex.

Getting reflow soldering right is crucial. Poor soldering can lead to weak connections, component failure, or even complete product malfunctions. By optimizing your reflow process, you ensure high-quality joints, reduce rework costs, and improve the overall reliability of your electronic products.

In the sections below, we’ll explore every aspect of reflow soldering, from crafting the perfect SMT reflow soldering profile to maintaining your equipment for consistent results.

Understanding the SMT Reflow Soldering Profile: The Heart of the Process

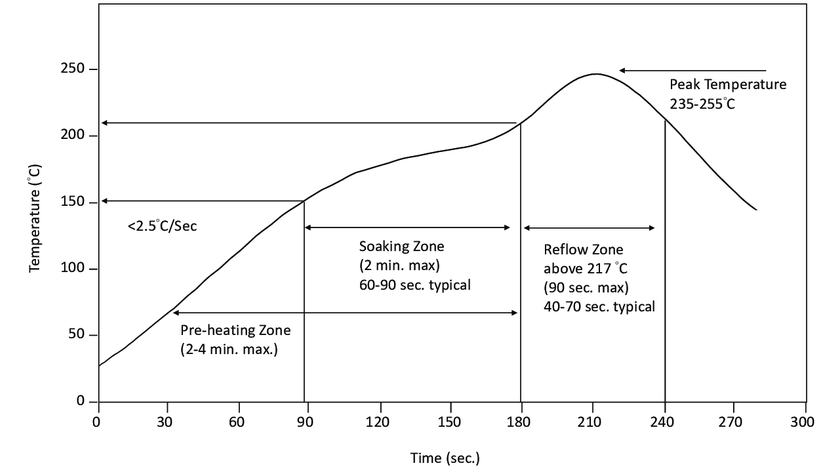

The SMT reflow soldering profile is a temperature-time graph that dictates how your PCB assembly is heated and cooled during the reflow process. A well-designed profile ensures that the solder paste melts correctly, forms strong bonds, and avoids damage to components. Let’s break down the four main stages of a typical reflow profile:

- Preheat Zone: This stage gradually raises the temperature of the PCB assembly, typically to 150-180°C over 60-90 seconds. The goal is to evaporate solvents in the solder paste and activate the flux without causing thermal shock to components.

- Thermal Soak Zone: Here, the temperature stabilizes between 150-200°C for about 60-120 seconds. This allows uniform heating across the board and prepares the solder paste for melting.

- Reflow Zone: The temperature peaks at 220-260°C (depending on the solder alloy) for 20-40 seconds. This is when the solder paste melts and forms joints. The “time above liquidus” (TAL) is critical—too short, and joints may not form; too long, and components can overheat.

- Cooling Zone: The assembly cools down at a controlled rate, usually 2-4°C per second, to solidify the solder joints without creating stress or cracks.

Creating the right SMT reflow soldering profile depends on your solder paste type (lead-free or leaded) and the thermal mass of your PCB and components. Always refer to the solder paste manufacturer’s datasheet for recommended settings and adjust based on your specific assembly.

Reflow Oven Temperature Settings: Precision Is Key

Reflow oven temperature settings directly impact the quality of your solder joints. Setting the correct temperatures for each zone of the oven ensures that the soldering process follows the intended profile. Here are some practical tips for dialing in your settings:

- Match the Solder Paste Requirements: For lead-free solder, peak temperatures often range from 235-250°C, while leaded solder typically requires 215-230°C. Exceeding these limits can damage components or cause intermetallic growth, weakening joints.

- Account for Board Size and Density: Larger or densely populated PCBs absorb more heat, so you may need to increase soak time or temperature slightly to ensure even heating.

- Use a Thermocouple for Accuracy: Attach a thermocouple to your PCB during a test run to measure actual temperatures across different zones. Compare these readings with your oven settings to fine-tune the profile.

- Regular Testing: Perform periodic temperature checks using professional profiling tools to ensure your oven maintains consistent performance over time.

Precision in reflow oven temperature settings can make the difference between a perfect joint and a costly defect. Always start with manufacturer guidelines and adjust based on real-world testing.

Common Reflow Soldering Defects: Causes and Solutions

Even with the best intentions, reflow soldering defects can occur. Identifying the causes of these issues is the first step to preventing them. Below, we’ll cover some frequent reflow soldering defects, their causes, and how to address them:

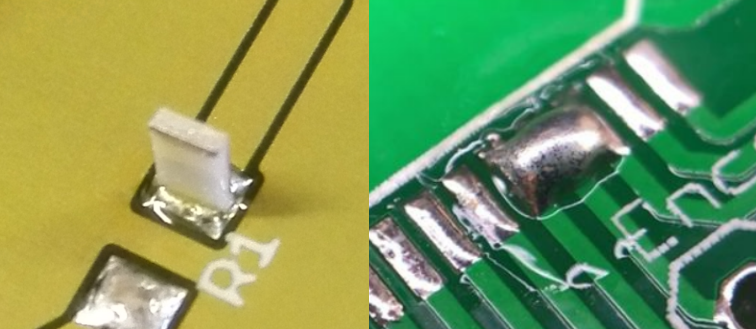

- Tombstoning: This happens when one end of a component lifts off the pad, resembling a tombstone. Causes include uneven heating, incorrect pad design, or excessive solder paste. To fix this, ensure uniform heating by optimizing your reflow profile and check pad layouts for symmetry.

- Cold Solder Joints: These weak, dull-looking joints occur due to insufficient heat or time above liquidus. Increase the peak temperature or extend the reflow zone duration to ensure proper melting.

- Bridging: Solder bridges form unwanted connections between pads, often due to excess solder paste or poor stencil design. Reduce paste volume and inspect stencil alignment to prevent this.

- Voiding: Voids are air pockets within solder joints, caused by outgassing during reflow. Minimize voiding by using a slower preheat ramp rate to allow gases to escape before the solder melts.

- Component Damage: Overheating can crack or delaminate components. Stick to recommended peak temperatures (usually below 260°C for most SMT parts) and avoid prolonged exposure to high heat.

By understanding these reflow soldering defects causes, you can tweak your process to minimize errors and achieve consistent, high-quality results.

Reflow Soldering Process Optimization: Tips for Peak Performance

Optimizing your reflow soldering process is about fine-tuning every detail to achieve efficiency and quality. Here are actionable strategies for reflow soldering process optimization:

- Customize Profiles for Each Assembly: No two PCB designs are identical. Test and adjust reflow profiles for each new board design, considering factors like component types, board thickness, and solder paste composition.

- Control Placement Accuracy: Misaligned components can lead to poor joints. Use high-precision placement machines and inspect component pins for damage before reflow.

- Minimize Oxidation: Oxidation during reflow can weaken joints. Consider using a nitrogen atmosphere in your oven to reduce oxygen exposure, especially for lead-free soldering.

- Monitor Conveyor Speed: The speed at which your PCB moves through the oven affects heating and cooling rates. Adjust conveyor speed to match the recommended profile durations—typically 60-120 cm/min for standard ovens.

- Batch Testing: Run small test batches with new profiles or materials before full production. Use X-ray inspection or visual checks to verify joint quality and make adjustments as needed.

Reflow soldering process optimization is an ongoing effort. Regularly review your results, gather data, and refine your approach to stay ahead of potential issues.

Reflow Soldering Equipment Maintenance: Keeping Your Oven in Top Shape

Your reflow oven is the heart of the soldering process, and proper reflow soldering equipment maintenance ensures consistent performance. Neglecting maintenance can lead to uneven heating, profile deviations, and increased defect rates. Follow these maintenance tips to keep your equipment running smoothly:

- Clean Regularly: Solder paste residues and flux vapors can build up inside the oven, affecting airflow and temperature uniformity. Clean the oven interior, conveyor belts, and exhaust systems weekly or after every major production run.

- Check Heating Elements: Inspect heating elements for wear or damage. Faulty elements can cause temperature inconsistencies, so replace them as needed to maintain accurate reflow oven temperature settings.

- Calibrate Sensors: Temperature sensors can drift over time. Use a calibrated thermocouple or profiling tool to verify sensor accuracy monthly and recalibrate if necessary.

- Inspect Conveyor Systems: Ensure the conveyor belt moves smoothly without jerks or misalignment. Lubricate moving parts and tighten loose components to prevent PCB mishandling during reflow.

- Monitor Exhaust and Ventilation: Clogged exhaust systems can trap heat or fumes, leading to safety hazards and poor soldering results. Clean or replace filters regularly to maintain proper airflow.

Schedule routine maintenance checks based on your production volume. A well-maintained oven not only extends equipment lifespan but also ensures reliable soldering outcomes every time.

Advanced Tips for Perfect SMT Joints

Beyond the basics, a few advanced techniques can further elevate your reflow soldering results:

- Use Solder Paste Inspection (SPI): Implement SPI systems to check solder paste volume and alignment before reflow. This reduces the risk of defects like bridging or insufficient solder.

- Profile for Lead-Free vs. Leaded Solder: Lead-free solder requires higher temperatures (up to 250°C) and narrower process windows. If switching between leaded and lead-free, always adjust profiles and test thoroughly to avoid thermal shock.

- Consider Vacuum Reflow: For high-reliability applications, vacuum reflow ovens can minimize voiding by reducing air pressure during soldering. While more expensive, this method is ideal for critical assemblies.

- Train Your Team: Ensure operators are well-versed in reflow soldering best practices, from profile setup to defect identification. Regular training keeps everyone aligned with the latest techniques.

These advanced strategies can help you achieve near-perfect SMT joints, even in challenging production environments.

Conclusion: Mastering Reflow Soldering for SMT Success

Reflow soldering is both an art and a science. By mastering the SMT reflow soldering profile, fine-tuning reflow oven temperature settings, addressing reflow soldering defects causes, optimizing the process, and maintaining your equipment, you can achieve perfect SMT joints every time. The secrets lie in precision, consistency, and continuous improvement.

Start by reviewing your current reflow process. Test your profiles, inspect your joints, and maintain your oven diligently. With the tips and strategies shared in this guide, you’re well on your way to producing high-quality, reliable PCB assemblies that meet the demands of modern electronics.

At ALLPCB, we’re committed to supporting your journey in electronics manufacturing. Explore our resources and services to take your PCB assembly to the next level.

ALLPCB

ALLPCB