Summary

This project developed a highly flexible, high-precision, safety-focused bionic robotic hand capable of grasping, lifting, placing, cleaning, organizing, and caregiving tasks for humanoid robotic platforms. The design emphasizes modularity, multi-modal sensing, and software-driven control to support adaptive operation in dynamic environments.

1. Key Innovations

- High integration

Using a ROS modular architecture, the design achieves compact integration of drivers, sensors, and the control unit, improving energy efficiency and portability. ROS hardware abstraction and middleware simplify efficient communication and synchronization between components.

- Multi-modal perception

The manipulator integrates tactile, visual, and force sensors. ROS-based data fusion enhances environmental awareness and improves operational safety and efficiency.

- High extensibility

A modular design with standardized key components facilitates rapid replacement and upgrades. Standardized interfaces ensure broad compatibility with third-party accessories and existing systems.

- AI-based learning

Machine learning and AI techniques are used to develop control algorithms that enable precise motion control and automatic adjustment based on environmental feedback, improving autonomy and adaptability in complex, dynamic tasks.

2. Design Justification and Architecture

The following sections summarize the main technical approaches and rationale behind the mechanical, electrical, and software subsystems.

- Mechanical structure design

- Overall structure:

The manipulator employs a cable-driven actuation approach using lightweight cables instead of heavy direct-drive motors, which increases range of motion and response speed. CAD and kinematic analysis were used to optimize cable routing. A dynamic tensioning system maintains stable joint behavior under load.

- Joint design:

Joint kinematics mimic human finger flexion and extension. Cable-and-bearing assemblies provide dexterity for complex gestures. Cable adjustability enables a wide range of motion profiles.

- Materials and manufacturing:

Components are fabricated from PLA where appropriate to reduce weight and cost and to enable 3D printing. Precision tuning, heat treatment, and surface coating processes were applied to meet durability and wear resistance requirements.

- Overall structure:

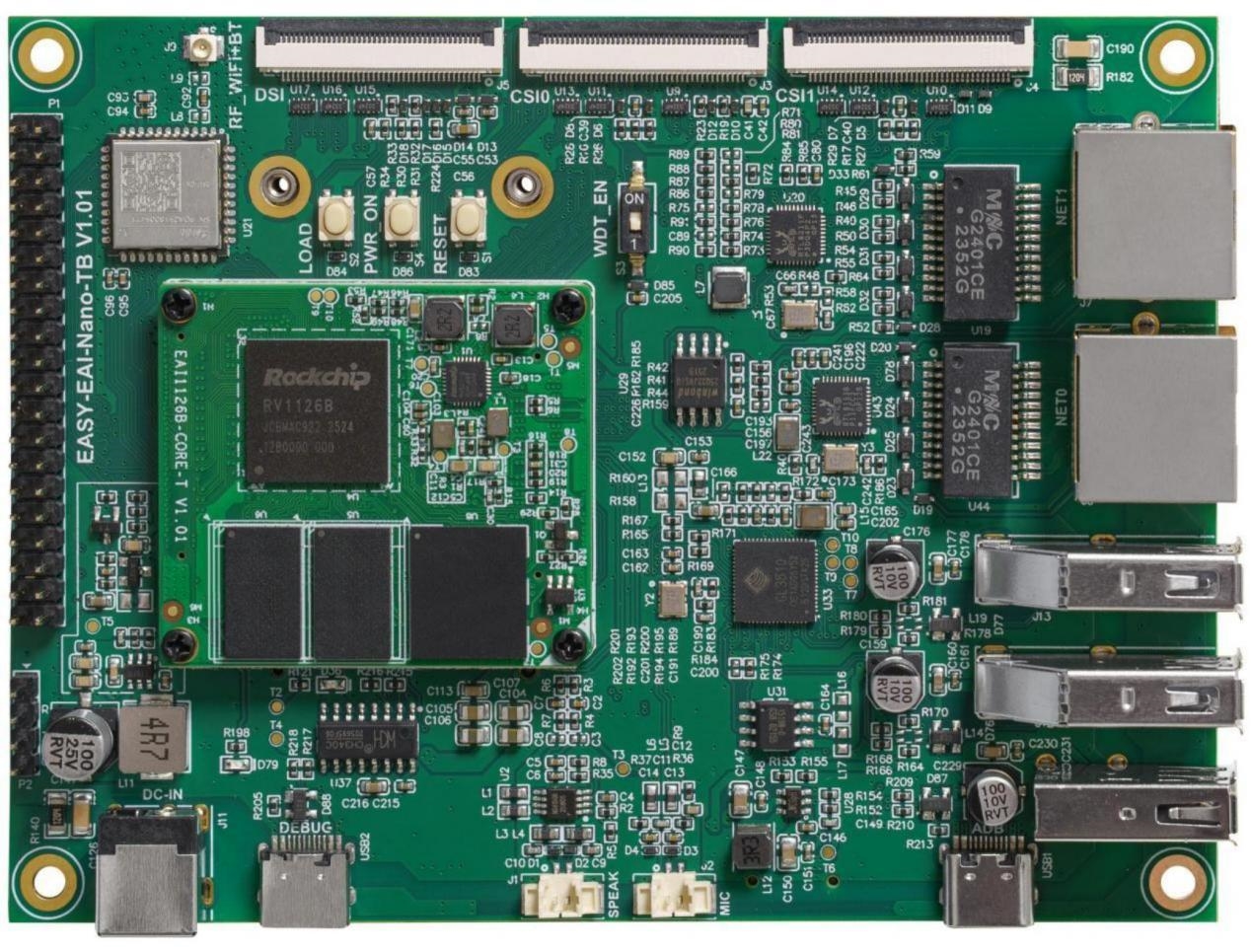

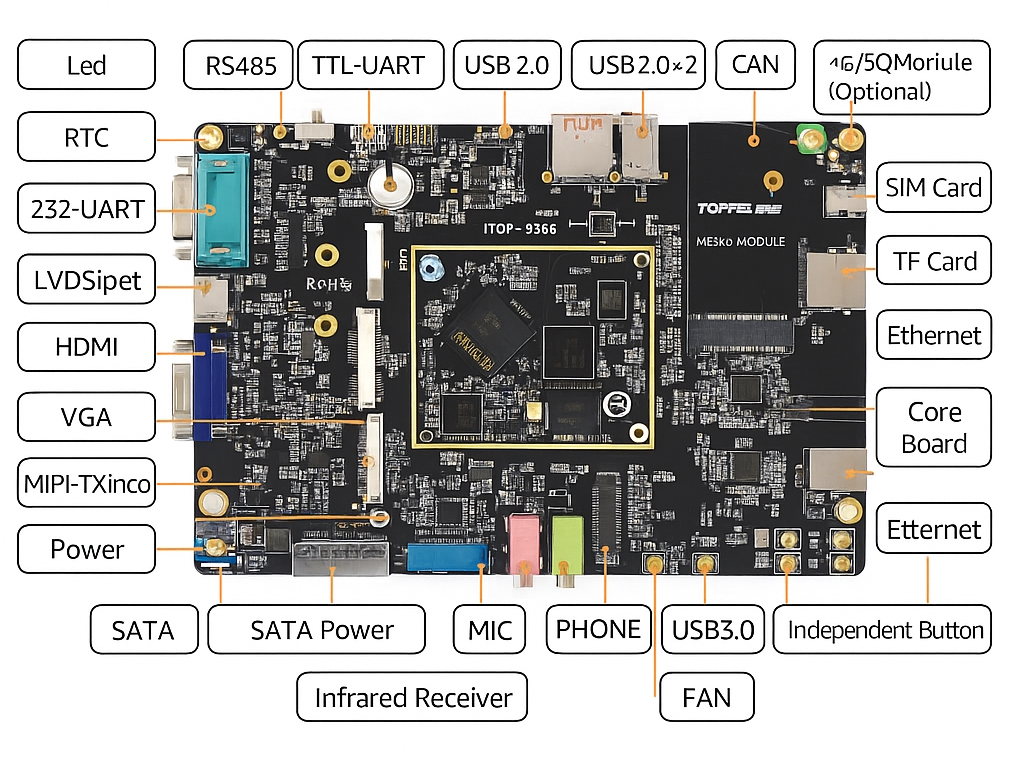

- Electrical architecture

- Power management:

The power management system provides stable supply to all subsystems and includes overload protection and safety interlocks.

- Sensor circuits:

Sensors such as BMP280 and MPU6050 are used for pressure, temperature, and attitude estimation, providing real-time environmental and inertial data.

- Control circuitry:

Control electronics include flash memory, CAN bus connectivity, and decoder circuits to tightly interconnect control elements and ensure timely, reliable command delivery.

- Auxiliary circuits:

ADC multiplexing and current sensing monitor power and operational status. Serial port isolation and an ESP12 communication module provide robust serial communication and network connectivity.

- Power management:

- Software design

- Low-level drivers:

On the STM32 F4 platform, clock, GPIO, DMA, ADC/DAC, and peripheral interfaces are configured to support precise sensor sampling and motor control.

- Linux environment and ROS:

Ubuntu 20.04 hosts ROS Melodic and Rviz to provide middleware, visualization, and integration for perception and planning modules.

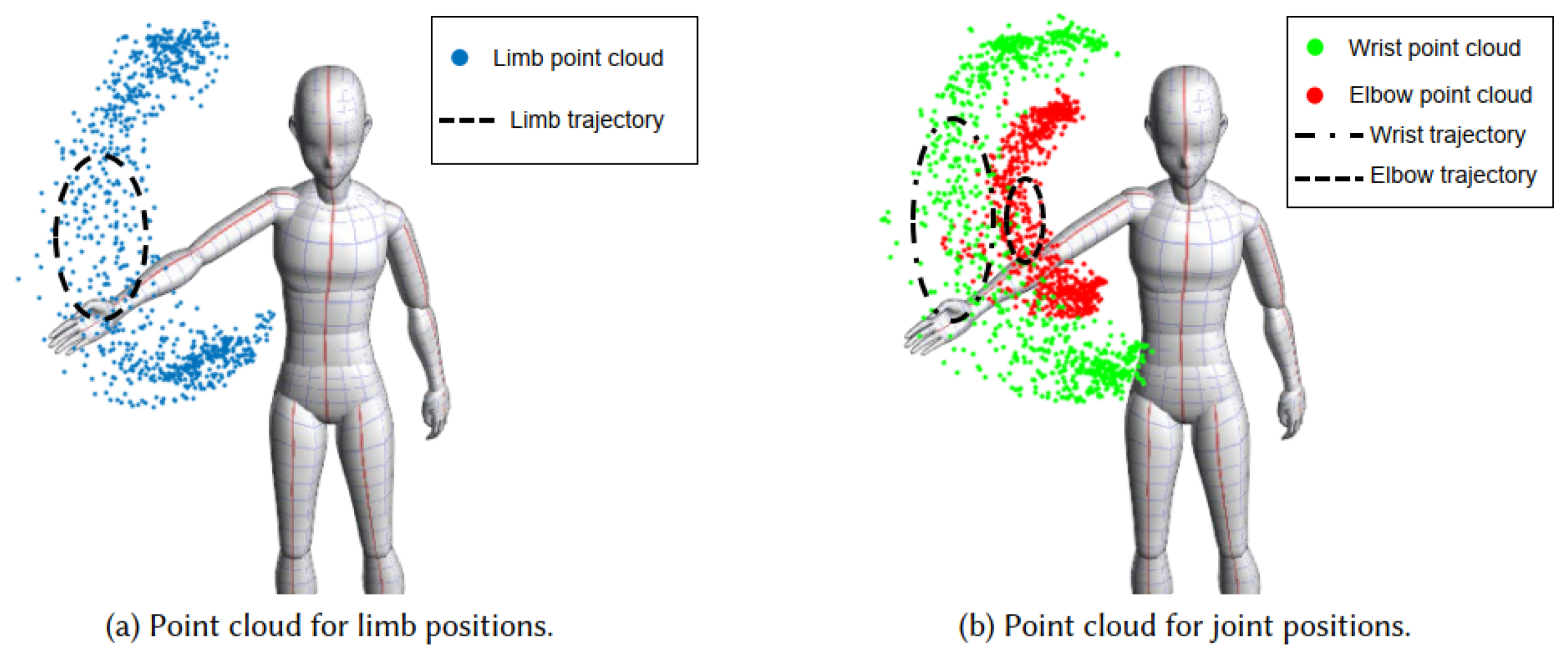

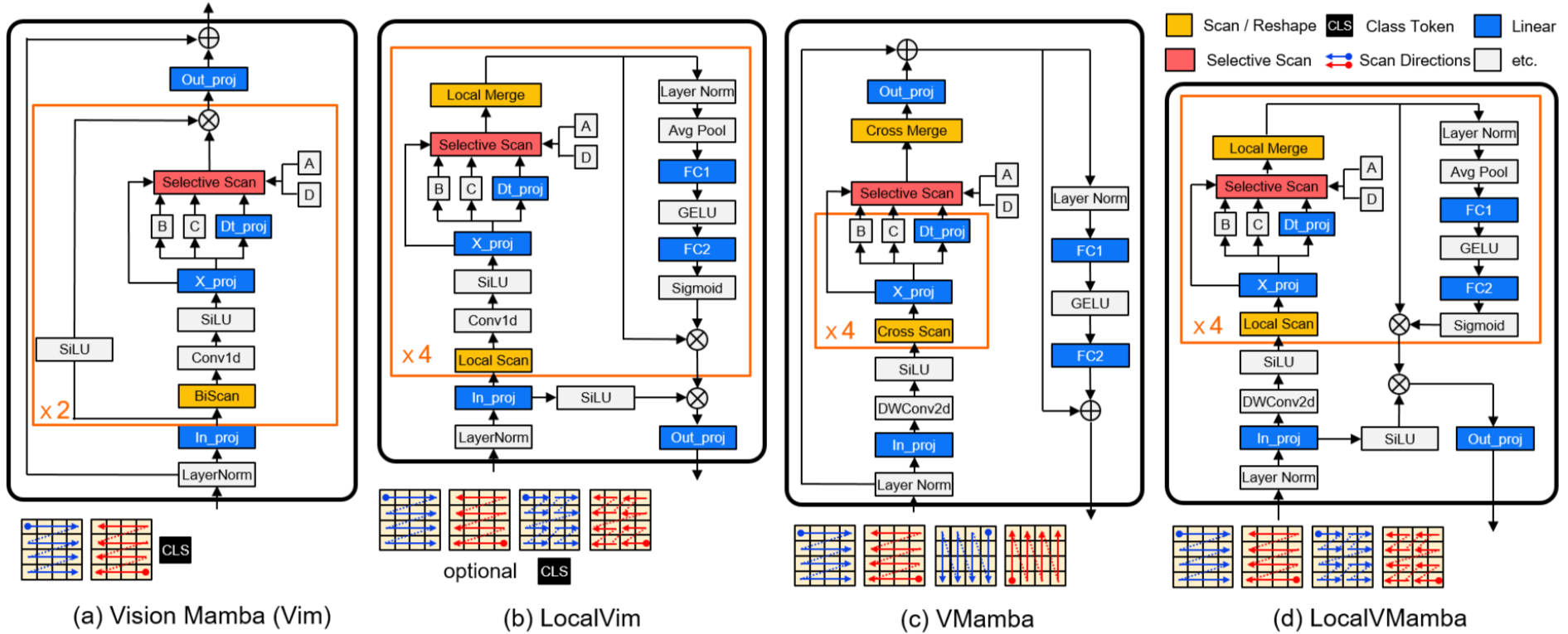

- Vision recognition:

Deep learning models are applied for object and gesture recognition to enable perception-driven manipulation and continuous improvement through training.

- Low-level drivers:

- Overall assessment

- Adaptability:

The cable-driven architecture supports multi-DOF motions and flexible interaction in cluttered or structured environments.

- Safety:

Mechanical and electrical safety measures, including emergency stop and overload protection, are implemented to mitigate operational risk.

- Modularity and cost effectiveness:

Modular componentization simplifies upgrades and maintenance while optimizing cost versus performance.

- Adaptability:

3. Hardware

Detailed hardware component selection, schematics, and PCB layouts are covered in the hardware documentation and BOM.

4. Software Design and Workflow

- Software layers and overall structure

- Low-level driver design

- MCU main program design

- Vision recognition system design

5. Testing

- System integration testing

- Functional verification and performance evaluation

ALLPCB

ALLPCB