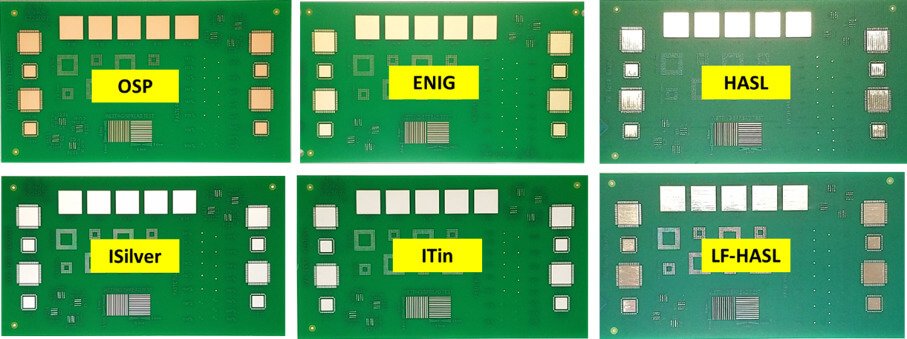

If you're searching for alternatives to immersion silver as a PCB surface finish, you're likely looking for options that balance cost, performance, and reliability for your specific project needs. In this comprehensive guide, we’ll explore popular alternatives like ENIG, OSP, and HASL, comparing their pros and cons against immersion silver. Whether you're deciding between ENIG vs immersion silver, OSP vs immersion silver, or HASL vs immersion silver, this PCB surface finish comparison will help you make an informed choice. Let’s dive into the details to understand which finish suits your application best.

Why Consider Alternatives to Immersion Silver?

Immersion silver is a widely used PCB surface finish due to its excellent conductivity, good solderability, and relatively low cost compared to some other finishes. However, it has drawbacks, such as a tendency to tarnish over time and potential issues with shelf life due to oxidation. These limitations often push engineers and manufacturers to explore alternatives that might offer better durability, cost-effectiveness, or environmental compliance.

In this blog, we’ll break down the key characteristics of immersion silver and compare it with three common alternatives: Electroless Nickel Immersion Gold (ENIG), Organic Solderability Preservative (OSP), and Hot Air Solder Leveling (HASL). By understanding the strengths and weaknesses of each, you can select the best surface finish for your PCB design.

What is Immersion Silver and Why Look for Alternatives?

Immersion silver is a lead-free surface finish applied through a chemical process that deposits a thin layer of silver onto the copper pads of a PCB. It provides a flat surface ideal for fine-pitch components and offers excellent electrical conductivity. However, immersion silver is prone to tarnishing when exposed to air or sulfur-containing environments, which can compromise solderability if the PCB is stored for extended periods (typically over 6-12 months).

Additionally, immersion silver may not be the best choice for applications requiring high durability or resistance to harsh conditions. Its cost, while moderate, can also be a factor when compared to cheaper options. These challenges make it essential to consider alternatives that might better meet specific project requirements, such as long-term reliability or lower production costs.

Key Pros of Immersion Silver

- Excellent solderability for surface-mount components.

- Flat surface, ideal for fine-pitch and BGA (Ball Grid Array) components.

- Good electrical conductivity for high-frequency applications.

- Lead-free and RoHS compliant.

Key Cons of Immersion Silver

- Prone to tarnishing and oxidation, reducing shelf life.

- Requires careful handling and storage to prevent degradation.

- Moderate cost, higher than some budget-friendly alternatives.

Alternative 1: ENIG (Electroless Nickel Immersion Gold) vs Immersion Silver

ENIG is one of the most popular alternatives to immersion silver, consisting of a layer of nickel beneath a thin layer of gold. The nickel acts as a barrier to protect the copper, while the gold provides excellent solderability and resistance to oxidation. Let’s compare ENIG vs immersion silver to see how it stacks up.

Pros of ENIG

- Durability: The gold layer prevents oxidation, offering a longer shelf life (often exceeding 12 months) compared to immersion silver’s typical 6-12 months.

- Flat Surface: Like immersion silver, ENIG provides a planar surface suitable for fine-pitch components and high-density designs.

- Reliability: Excellent for applications requiring multiple soldering cycles, as the gold layer withstands thermal stress better.

- Signal Integrity: The nickel layer helps maintain signal integrity in high-frequency applications, often outperforming immersion silver in impedance control (typical impedance variation of less than 5% compared to 7-10% for immersion silver in some studies).

Cons of ENIG

- Cost: ENIG is significantly more expensive than immersion silver, often 20-30% higher due to the use of gold and the complex plating process.

- Black Pad Issue: A potential defect known as “black pad” can occur due to improper nickel plating, leading to poor solder joints. This risk, though rare with modern processes, is not a concern with immersion silver.

When to Choose ENIG Over Immersion Silver

ENIG is ideal for high-reliability applications, such as medical devices or aerospace electronics, where long-term performance and resistance to environmental factors are critical. If cost is a concern or your PCB will be assembled shortly after production, immersion silver might still be a better choice.

Alternative 2: OSP (Organic Solderability Preservative) vs Immersion Silver

OSP is a water-based, organic coating applied to copper pads to protect them from oxidation. It’s an environmentally friendly, lead-free option often chosen for its low cost. Let’s dive into OSP vs immersion silver to understand its advantages and limitations.

Pros of OSP

- Cost-Effective: OSP is one of the cheapest surface finishes available, often 30-50% less expensive than immersion silver, making it attractive for budget-conscious projects.

- Environmentally Friendly: Being water-based and free of heavy metals, OSP aligns with strict environmental regulations.

- Good Solderability: It provides excellent solder wetting during assembly, comparable to immersion silver when the PCB is fresh.

- Flat Surface: Similar to immersion silver, OSP offers a planar surface for fine-pitch components.

Cons of OSP

- Limited Shelf Life: OSP degrades faster than immersion silver, with a typical shelf life of 3-6 months compared to 6-12 months for immersion silver, as the organic coating wears off over time.

- Handling Sensitivity: The finish is fragile and can be damaged by improper handling or exposure to contaminants, unlike the more robust immersion silver.

- Not Suitable for Multiple Reflows: OSP may not withstand multiple soldering cycles, as the coating can break down under repeated heat exposure, whereas immersion silver holds up better.

When to Choose OSP Over Immersion Silver

OSP is best for low-cost, high-volume production where PCBs will be assembled quickly after manufacturing. If your project involves long storage times or complex assembly processes, immersion silver or other finishes might be more suitable.

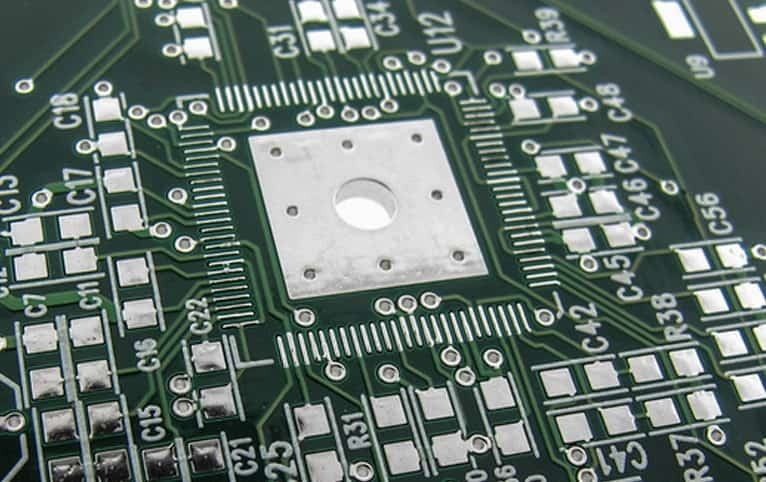

Alternative 3: HASL (Hot Air Solder Leveling) vs Immersion Silver

HASL is one of the oldest and most widely used PCB surface finishes, involving dipping the board in molten solder and using hot air to level the coating. It comes in both leaded and lead-free versions. Let’s compare HASL vs immersion silver to see where it fits as an alternative.

Pros of HASL

- Low Cost: HASL is typically 40-60% cheaper than immersion silver, making it a go-to option for cost-sensitive projects.

- Good Solderability: The solder coating ensures excellent wetting during assembly, often matching or exceeding immersion silver in initial performance.

- Durability: HASL offers a robust finish that resists handling damage and has a shelf life of over 12 months, often outlasting immersion silver in storage.

Cons of HASL

- Uneven Surface: Unlike the flat surface of immersion silver, HASL can result in uneven solder thickness, making it less suitable for fine-pitch or BGA components (variations can be as high as 50-100 microns compared to less than 1 micron for immersion silver).

- Thermal Shock: The high temperatures used in the HASL process (around 260°C for lead-free solder) can stress the PCB, potentially causing warpage or delamination, a risk not present with immersion silver’s room-temperature process.

- Environmental Concerns: While lead-free HASL is available, traditional leaded HASL is not RoHS compliant, unlike immersion silver.

When to Choose HASL Over Immersion Silver

HASL is a great choice for simple, cost-effective designs with larger components and through-hole technology. For modern, high-density designs requiring precise placement, immersion silver’s flatness makes it a better option.

PCB Surface Finish Comparison: Key Factors to Consider

Choosing the right surface finish depends on several factors unique to your project. Below is a detailed PCB surface finish comparison across critical parameters to help you weigh immersion silver against ENIG, OSP, and HASL.

| Finish | Cost (Relative) | Shelf Life | Surface Flatness | Solderability | Environmental Compliance |

|---|---|---|---|---|---|

| Immersion Silver | Medium | 6-12 months | Excellent | Good | RoHS Compliant |

| ENIG | High | 12+ months | Excellent | Excellent | RoHS Compliant |

| OSP | Low | 3-6 months | Excellent | Good (short-term) | RoHS Compliant |

| HASL (Lead-Free) | Low | 12+ months | Poor | Excellent | RoHS Compliant |

Cost vs Performance Trade-Offs

If budget is your primary concern, OSP and HASL are the most economical choices, though they come with trade-offs in shelf life and surface quality, respectively. ENIG offers top-tier performance but at a higher cost, while immersion silver strikes a middle ground in both cost and capability.

Application-Specific Needs

For high-frequency designs, ENIG and immersion silver provide better signal integrity due to consistent impedance control. For quick-turn, low-cost projects, OSP can work well if assembly happens soon after production. HASL remains a solid pick for traditional, less complex boards.

How to Choose the Right Surface Finish for Your PCB

Selecting between immersion silver and its alternatives comes down to understanding your project’s priorities. Here are some actionable tips to guide your decision:

- Evaluate Storage and Assembly Timeline: If your PCBs will be stored for months before assembly, prioritize finishes with longer shelf lives like ENIG or HASL over OSP or immersion silver.

- Consider Component Density: For high-density designs with fine-pitch components, opt for flat finishes like immersion silver, ENIG, or OSP rather than HASL.

- Balance Budget and Performance: If cost is critical, start with OSP or HASL, but be aware of their limitations. For premium performance, ENIG might justify the higher investment.

- Assess Environmental Conditions: For harsh environments or high humidity, ENIG’s resistance to oxidation outperforms immersion silver’s vulnerability to tarnishing.

Conclusion: Finding the Best Alternative to Immersion Silver

Immersion silver is a versatile PCB surface finish, but it’s not always the perfect fit for every application. By exploring alternatives like ENIG, OSP, and HASL, you can find a solution tailored to your project’s needs. ENIG offers superior durability and reliability at a higher cost, OSP provides a budget-friendly and eco-conscious option for short-term use, and HASL remains a low-cost, durable choice for simpler designs.

Understanding the pros and cons of each finish—whether it’s ENIG vs immersion silver, OSP vs immersion silver, or HASL vs immersion silver—empowers you to make a decision that optimizes both performance and cost. Use this PCB surface finish comparison as a starting point to align your choice with your design requirements, environmental conditions, and budget constraints.

At ALLPCB, we’re committed to helping you navigate these choices with expert guidance and high-quality manufacturing solutions. Whether you’re leaning toward immersion silver or one of its alternatives, we’re here to support your next PCB project with precision and care.

ALLPCB

ALLPCB