Introduction

Whenever logic circuits switch states in CMOS VLSI designs, energy is consumed because transistor capacitances are charged to defined logic levels. Even though the objective is to minimize power, small per-transition energy can accumulate into substantial dynamic power when many logic elements toggle during operation. During device design, the chip's energy dissipation as heat must be estimated to determine necessary cooling measures, potential heatsink requirements, whether an exposed thermal pad is needed, or whether special packaging is required to ensure reliability.

Key points

- Individual gate power can usually be calculated manually or with simulation tools.

- Direct power calculation becomes difficult when many logic blocks toggle during operation.

- Reliable power estimates can be used in thermal simulation to evaluate reliability and select appropriate packaging.

Estimating switching activity and power

Modern integrated circuits are structurally complex, and estimating power in VLSI designs is challenging. These products contain multiple logic blocks, some of which operate independently so that only a subset may be active at any given time. Two different bitstreams carrying the same input power do not necessarily produce the same toggling activity. Different input bitstreams produce different signal changes across the design, resulting in different power consumption.

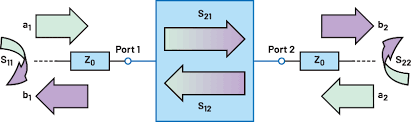

Because power depends strongly on input data and circuit structure, probability-based methods driven by logic simulation are typically used to determine signal switching activity. Logic elements also dissipate energy during switching.

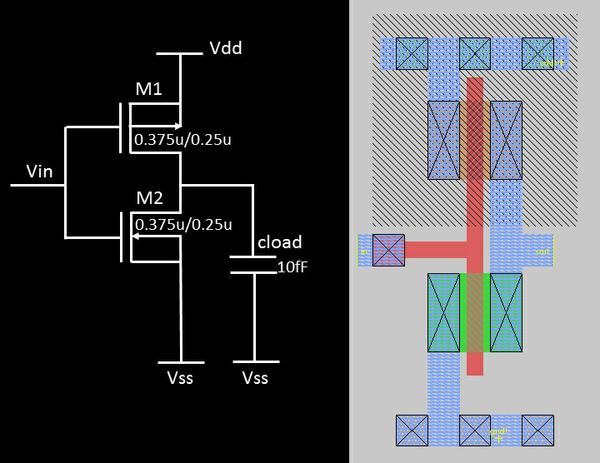

C represents the total capacitance charged and discharged by the switching logic. The voltage term is the supply voltage Vdd. Leakage current is often neglected in this expression, although it is important in thermal simulation. Note that this formula describes dynamic power; the actual energy dissipated as heat also depends on conduction resistances in the transistors and can be simulated with accurate transistor SPICE models.

One comprehensive method to estimate average signal activity is Monte Carlo simulation followed by statistical analysis. After determining the average number of toggling elements per clock cycle, that value can be multiplied by the expected per-element power to obtain the total dynamic power. Because logic elements have finite on-resistance, a fraction of the switching energy is dissipated as heat.

With modern microprocessors containing billions of transistors, the cumulative heat from switching is significant and requires careful simulation-based assessment.

Using power estimates

Once an estimate of dynamic switching power is available, it can be used in circuit or device thermal simulations to examine how packaging and PCB characteristics affect heat transfer from the device to the surrounding board, air, and any heatsink. These package-level simulations support preliminary reliability assessments and can prompt design changes before prototyping.

Because these evaluations are typically performed during VLSI design, packaging details may be approximate. Nevertheless, they allow design teams to evaluate different package options and predict steady-state temperatures under various conditions. Such reliability simulations often use field solvers and may involve multiphysics problems including airflow, or simpler thermal simulations based on the heat equation.

After assessing power based on expected signal activity, package simulations can be run to create worst-case scenarios, estimate heat dissipation and temperature rise, and evaluate product reliability. Because packaging choices such as a thermal pad on the package bottom can substantially affect operating temperature, designers should perform these simulations before prototypes are built. Integrating these analyses into the design and reliability workflow helps identify packaging needs early.

An important consideration in VLSI design is leakage current at elevated temperatures. If a design is not managed properly, high-frequency toggling in core logic may raise device temperature until leakage current accounts for a large portion of the dissipated energy. This temperature rise can lead to thermal runaway and eventual device failure. Simulations should therefore consider leakage behavior to assess reliability and determine allowable maximum junction temperatures.

Tools and resources

System-level analysis tools can simplify the process of estimating power from signal switching and evaluating thermal reliability. For example, Cadence Celsius EC Solver is a tool that analyzes fluid flow and heat transfer in electronic systems using unstructured meshing techniques to solve for convection, conduction, and radiation. It can model airflow, temperature, and heat transfer in electronic assemblies and evaluate natural convection, forced convection, solar heating, and liquid cooling scenarios.

ALLPCB

ALLPCB