1. Definition and Overview

PLC Definition

A PLC is a digital electronic system designed for industrial environments. It uses programmable memory to store instructions that execute logic operations, sequence control, timing, counting, and arithmetic operations, and it controls various types of mechanical equipment or production processes through digital or analog inputs and outputs. A PLC typically comprises a CPU, instruction and data memory, input/output interfaces, a power supply, and analog/digital conversion modules.

Embedded System Definition

An embedded system is a device composed of hardware and software that can operate independently. It is application-centered and based on modern computing technologies, allowing flexible tailoring of hardware and software modules according to user requirements such as functionality, reliability, cost, size, power consumption, and environment. Embedded system hardware includes signal processors, memory, and communication modules, while the software side includes the runtime environment and operating system.

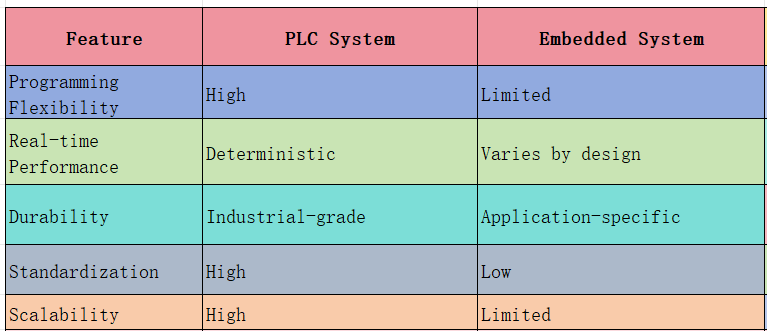

2. Differences Between PLC and Embedded Systems

Application Domains

PLC: Mainly used in industrial automation control domains such as power, oil and gas, chemical, and machinery manufacturing. PLCs are designed to withstand complex industrial environments and emphasize stability and reliability.

Embedded systems: Widely used across devices such as aerospace, automotive, consumer electronics, and smart home products. Embedded systems are application-specific and highly customizable.

System Architecture

PLC: Built on a modular architecture where different modules can be added to implement specific functions. Both hardware and software are standardized, making selection and configuration convenient.

Embedded systems: Usually have fixed hardware and software configurations tailored to a specific application. Hardware and software are tightly integrated to form a complete system.

Programming Languages

PLC: Commonly programmed with ladder diagram language, a graphical programming method that is easy to learn and use. PLCs also support textual languages such as Instruction List and Structured Text.

Embedded systems: Typically developed in C, C++, and other high-level languages. These languages provide flexibility and advanced capabilities for complex requirements.

Real-Time Performance

PLC: Offers strong real-time performance, able to rapidly respond to external inputs and produce control outputs. This is critical for ensuring stability and safety in industrial processes.

Embedded systems: Also have real-time requirements, but the actual performance depends on system design and application needs. Some embedded applications require millisecond or microsecond level response times.

Reliability

PLC: Uses industrial-grade components and modular design, providing reliable and stable operation. PLCs undergo rigorous environmental and performance testing to ensure operation in harsh industrial conditions.

Embedded systems: Reliability varies with design and implementation. They require customization and optimization for specific applications to meet stability and reliability requirements.

Development Difficulty

PLC: Development is relatively easier because of graphical programming and less need to understand low-level hardware and software details. PLCs also have extensive development resources and documentation.

Embedded systems: Development is generally more complex, involving low-level drivers and operating system work tied to specific hardware. Considerations such as power consumption, size, and cost add to the complexity.

Cost

PLC: Typically higher unit cost due to more functions, interfaces, and industrial-grade components. Considering stability, reliability, and development efficiency, PLCs often present favorable overall value in industrial applications.

Embedded systems: Cost varies with requirements and design. Simple embedded solutions may be low cost, while complex embedded systems can be expensive.

3. Conclusion

PLCs and embedded systems have distinct characteristics and advantages suited to different scenarios. PLCs are suited to industrial automation with an emphasis on stability, reliability, and simpler development methods. Embedded systems offer high specialization, flexibility, and a wide range of functions and interfaces. The choice between a PLC and an embedded system should be based on application requirements, budget, and technical constraints.

ALLPCB

ALLPCB