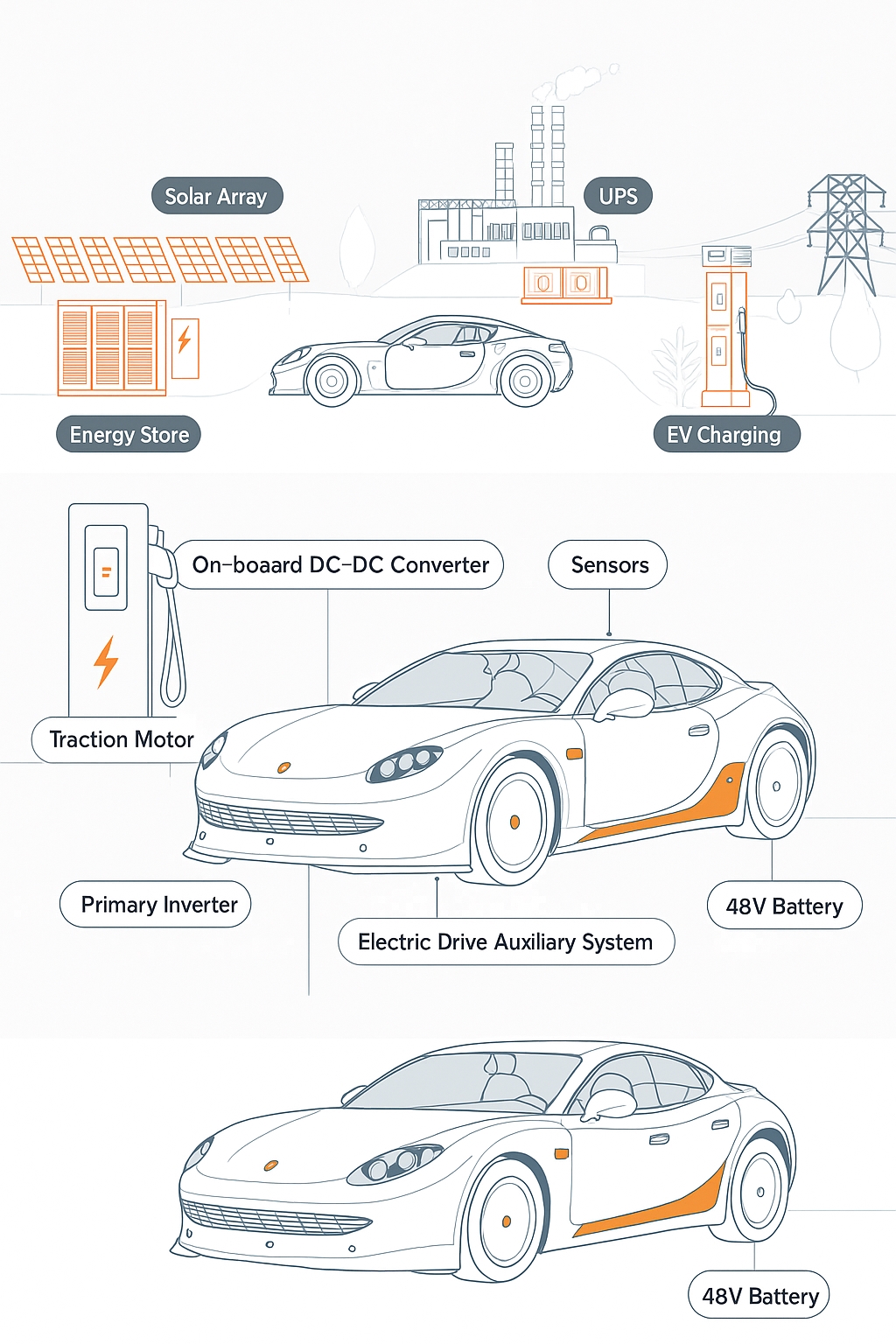

Rising efficiency requirements in automotive and renewable energy

Rising efficiency demands are affecting electronics application design across automotive and renewable energy sectors. For electric vehicles (EVs), higher efficiency translates to longer driving range; in renewable energy, higher conversion efficiency means more solar or wind energy is converted into electrical power.

Higher voltages reduce current and losses

Both sectors rely heavily on switched power electronics, which drives demand for higher-voltage devices. According to Ohm's law and power relationships, power loss in a circuit scales with the square of current. Correspondingly, if voltage is doubled for a given power level, current is halved and losses fall to one quarter. To reduce transmission losses, utilities commonly use very high voltages; for example, transmission voltages in the UK often reach 275 kV or 400 kV.

Utilities use heavy-duty transformers and related equipment to manage high transmission voltages, but automotive and renewable energy applications are more complex because they involve many electronic subsystems.

Role of converters, inverters, and power MOSFETs

Converters and inverters based on switched power electronics are central to renewable energy plants and electric vehicles. Both MOSFETs and IGBTs can be used in these systems, but MOSFETs dominate many power electronics applications because they typically require lower gate drive power, switch faster, and are more efficient at lower voltages.

Power MOSFETs must perform three main functions: blocking, switching, and conduction. During switching, a MOSFET must be able to interrupt the large voltage between drain and source; during blocking it must withstand the system rated voltage; and during conduction and switching it must meet the requirements for circuit losses and switching frequency. Conduction and switching losses both affect overall efficiency. Higher switching frequencies enable smaller and lighter systems, which is important for EV and industrial applications.

Silicon limits and the move to SiC

The trend toward higher voltages is pushing conventional silicon MOSFETs to their limits. Achieving both low RDS(on) and low gate charge for fast switching becomes increasingly difficult and costly at higher voltages. Designers have therefore turned to silicon carbide (SiC) to improve efficiency. SiC is a wide-bandgap material with advantages over silicon, including higher thermal conductivity, lower thermal expansion coefficient, and higher maximum current density. SiC also has a higher critical breakdown field strength, so thinner devices can meet rated voltage requirements and device size can be significantly reduced.

SiC MOSFETs are now available with breakdown voltage ratings approaching 10 kV, while silicon MOSFETs are typically limited to around 1.5 kV. SiC devices exhibit lower switching losses and can operate at higher frequencies, enabling better efficiency for high-current, high-power applications that run at elevated temperatures.

Manufacturing and device examples

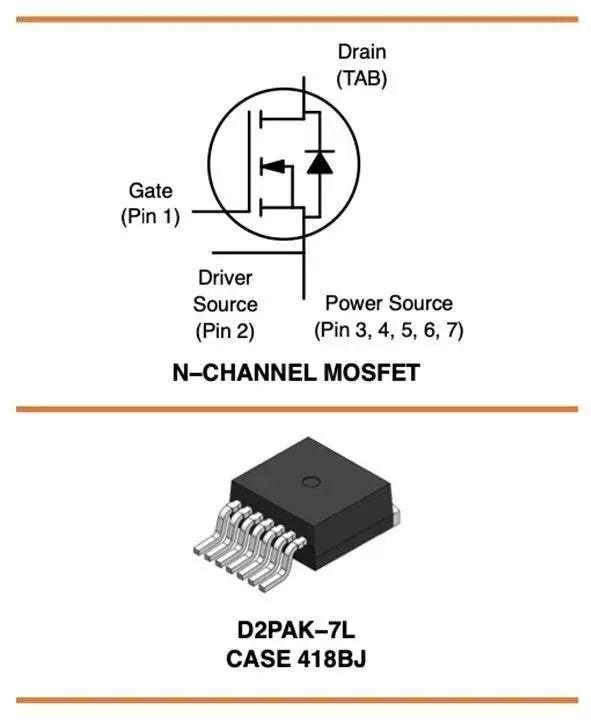

One device in this class is the NTBG028N170M1, a high-voltage SiC MOSFET optimized for fast switching at high voltages. It is an N-channel planar device with a VDSS of 1700 V and a VGS range of -15/+25 V.

The NTBG028N170M1 supports continuous drain current (ID) up to 71 A and pulse drain current up to 195 A. Its typical RDS(on) is 28 mΩ, which helps reduce conduction losses. The total gate charge QG(tot) is 222 nC, which helps limit switching losses at high frequencies. The device is offered in a D2PAK–7L surface-mount package to reduce parasitic effects during operation.

Implications for power electronic design

As system voltages continue to rise, conventional silicon MOSFETs are reaching practical limits for future high-voltage requirements. SiC devices offer a path to higher efficiency and smaller component sizes for demanding high-voltage, high-temperature power applications.

ALLPCB

ALLPCB