When designing a printed circuit board (PCB) for home appliance control systems, selecting the right substrate material is critical to ensure performance, durability, and cost-effectiveness. Whether you're working on a washing machine, microwave, or smart thermostat, the PCB material impacts how well the device operates under various conditions. In this comprehensive guide, we’ll explore popular PCB materials like FR-4, CEM-1, high-temperature substrates, flexible materials, and metal core options, specifically for home appliance applications. We’ll also compare these materials and discuss key factors affecting PCB material selection for home appliances to help you make an informed decision.

Why PCB Material Selection Matters for Home Appliances

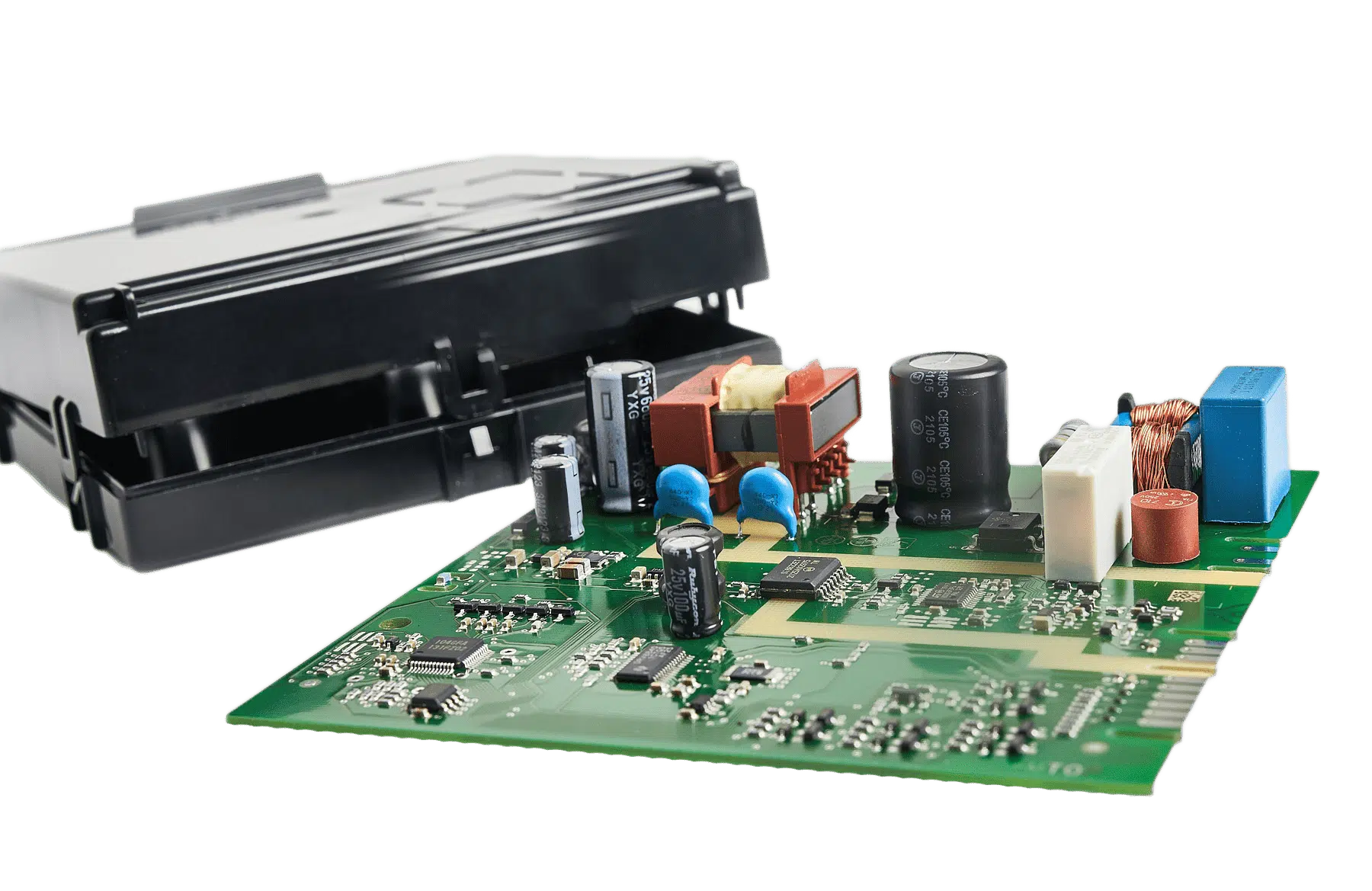

Home appliance control PCBs are the backbone of modern devices, managing everything from temperature regulation in refrigerators to motor control in dishwashers. The substrate material you choose directly affects the board’s electrical performance, thermal management, mechanical strength, and overall reliability. A poor choice can lead to overheating, signal interference, or even premature failure of the appliance. By understanding the properties of different materials like FR-4 materials for home appliance PCBs or metal core PCB materials for home appliances, you can optimize your design for both functionality and longevity.

In the sections below, we’ll dive into the characteristics of each material, their suitability for home appliance applications, and how they compare across critical parameters.

Overview of Common PCB Materials for Home Appliance Control

Let’s break down the most commonly used PCB substrate materials for home appliance control systems. Each material has unique properties that make it suitable for specific applications, environments, and budgets.

1. FR-4 Materials for Home Appliance PCBs

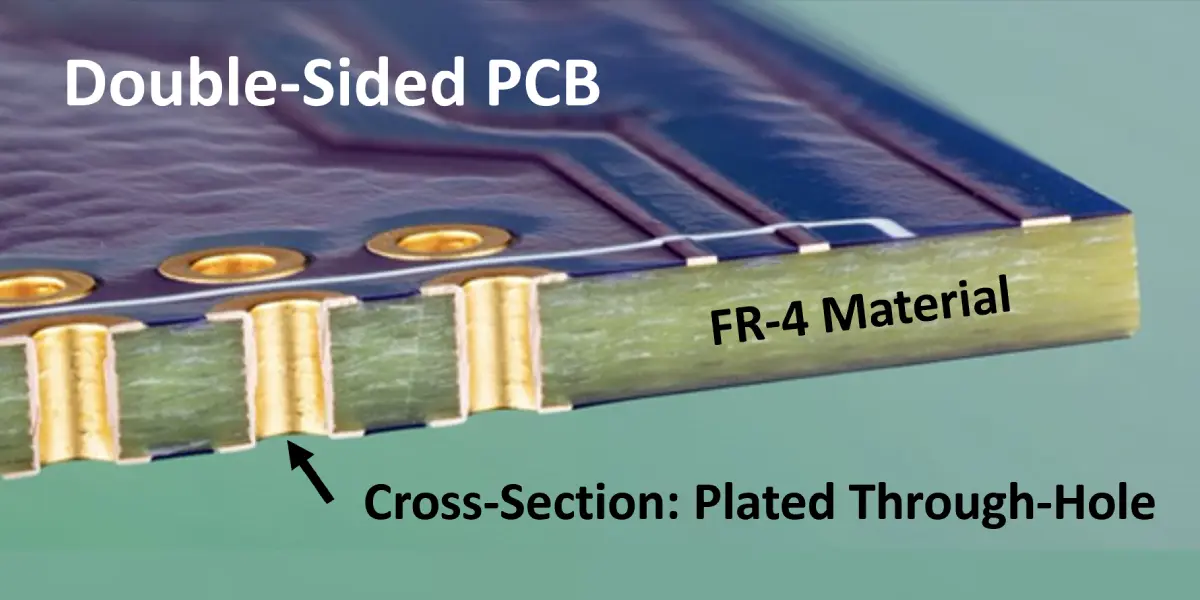

FR-4 is the most widely used PCB substrate material, known for its versatility and affordability. Made from woven fiberglass cloth with an epoxy resin binder, FR-4 offers a good balance of electrical insulation, mechanical strength, and thermal stability. Its dielectric constant (Dk) typically ranges from 4.2 to 4.5 at 1 MHz, making it suitable for low-to-medium frequency applications commonly found in home appliances like coffee makers or air conditioners.

FR-4 can withstand temperatures up to 130°C (Tg, glass transition temperature), which is adequate for most home appliances that don’t experience extreme heat. It also has a low dissipation factor (Df) of about 0.02, ensuring minimal signal loss. However, for appliances with high heat output, such as ovens, FR-4 may not be the best choice unless enhanced with higher Tg versions (up to 170°C).

2. CEM-1 Materials for Home Appliance PCBs

CEM-1 (Composite Epoxy Material-1) is a cost-effective alternative to FR-4, often used in budget-friendly consumer electronics. It consists of a woven glass fabric surface with a paper core, bonded with epoxy resin. While it offers decent electrical properties with a Dk of around 4.5-5.0, its mechanical strength and thermal resistance are lower than FR-4, with a Tg of about 110°C.

CEM-1 is ideal for simple home appliance control PCBs, such as those in basic timers or low-power fans, where cost is a priority over performance. However, it’s not recommended for appliances exposed to high humidity or temperature fluctuations due to its tendency to absorb moisture and delaminate.

3. High-Temperature PCB Materials for Home Appliances

For home appliances that operate in high-heat environments, such as microwaves, toasters, or induction cooktops, high-temperature PCB materials are essential. These substrates, often enhanced versions of FR-4 or specialized materials like polyimide, have a higher Tg (up to 200°C or more) and better thermal conductivity.

Polyimide-based materials, for instance, can handle continuous temperatures above 250°C and offer excellent chemical resistance. Their Dk is typically around 3.5, which supports better signal integrity at higher frequencies. However, these materials are more expensive, so they’re reserved for applications where thermal stability is non-negotiable.

4. Flexible PCB Materials for Home Appliances

Flexible PCB materials, often made from polyimide or polyester films, are gaining popularity in modern home appliances with compact or unconventional designs. These materials allow the PCB to bend or fold, fitting into tight spaces in devices like smart vacuums or wearable home automation controllers.

Flexible substrates have a Dk of about 3.2-3.5 and can operate in temperatures ranging from -40°C to 150°C, depending on the specific material. They also offer excellent fatigue resistance, enduring repeated bending without cracking. However, their cost is higher than rigid materials, and they may not support heavy components or high-power circuits as effectively.

5. Metal Core PCB Materials for Home Appliances

Metal Core PCBs (MCPCBs) are designed for superior thermal management, making them ideal for home appliances with significant heat dissipation needs, such as LED lighting systems or high-power motor controllers in washing machines. These substrates feature a metal base layer, usually aluminum or copper, which acts as a heat sink with thermal conductivity values ranging from 1 to 4 W/mK for aluminum and up to 400 W/mK for copper.

While MCPCBs excel in heat dissipation, their electrical insulation properties are achieved through a thin dielectric layer, which can limit their use in high-frequency applications. They are also heavier and more expensive than standard FR-4 or CEM-1 materials.

Comparing Different PCB Materials for Home Appliance Applications

To help you choose the right material, let’s compare FR-4, CEM-1, high-temperature, flexible, and metal core PCB materials across key performance metrics relevant to home appliance control systems.

- Cost: CEM-1 is the most affordable, followed by FR-4. High-temperature, flexible, and metal core materials are significantly more expensive due to their specialized properties.

- Thermal Resistance: Metal core and high-temperature materials outperform others, withstanding temperatures above 200°C. FR-4 and CEM-1 are limited to 130°C and 110°C, respectively, while flexible materials vary widely (up to 150°C).

- Mechanical Strength: FR-4 offers the best balance of rigidity and durability for rigid PCBs. CEM-1 is less robust, while flexible materials prioritize bendability over strength. Metal core PCBs are strong but heavy.

- Electrical Performance: High-temperature and flexible materials often have lower Dk values (around 3.5), supporting better signal integrity. FR-4 and CEM-1 are adequate for low-frequency applications with Dk around 4.5.

- Application Suitability: FR-4 suits most general-purpose home appliances. CEM-1 works for low-cost, simple devices. High-temperature materials are for heat-intensive appliances, flexible materials for compact designs, and metal core for high-power, heat-dissipating systems.

Factors Affecting PCB Material Selection for Home Appliances

Choosing the right PCB substrate for your home appliance control board requires careful consideration of several factors. Here are the most important aspects to evaluate:

1. Operating Environment

The environment in which the appliance operates plays a huge role in material selection. For instance, a refrigerator PCB may face humidity and cold temperatures, requiring a material with low moisture absorption like FR-4. On the other hand, an oven control board needs high-temperature PCB materials to handle sustained heat above 150°C.

2. Electrical Requirements

Consider the frequency and power demands of the appliance. For low-frequency control signals in a basic fan, FR-4 or CEM-1 is sufficient. However, smart home devices with high-speed communication may benefit from materials with lower dielectric constants, such as flexible polyimide substrates.

3. Thermal Management Needs

Appliances generating significant heat, like induction cooktops or high-power blenders, require materials with excellent thermal conductivity. Metal core PCB materials for home appliances are often the best choice here, as they efficiently dissipate heat and prevent component damage.

4. Mechanical Constraints

If the appliance design requires the PCB to fit into a tight or curved space, flexible PCB materials for home appliances are ideal. For larger, rigid boards supporting heavy components, FR-4 provides the necessary mechanical stability.

5. Cost and Manufacturing Budget

Budget constraints often dictate material choice, especially for mass-produced appliances. CEM-1 materials for home appliance PCBs are a go-to for low-cost products, while premium materials like metal core or high-temperature substrates are reserved for high-end or specialized devices.

6. Regulatory and Safety Standards

Home appliances must comply with safety and environmental standards, such as RoHS (Restriction of Hazardous Substances). Ensure the chosen material meets flame retardancy ratings (e.g., UL94 V-0 for FR-4) and other regulatory requirements to avoid safety risks.

How to Choose the Right PCB Material for Your Project

Selecting the ideal PCB material for your home appliance control board involves balancing performance needs with budget constraints. Start by identifying the specific requirements of your appliance—consider the operating temperature range, electrical demands, and physical design constraints. Then, match these needs to the material properties discussed above.

For example, if you’re designing a control board for a budget-friendly electric kettle, FR-4 or CEM-1 might suffice due to moderate temperature and power needs. However, for a high-end induction stove with significant heat output, investing in metal core or high-temperature materials ensures reliability and safety.

Additionally, collaborate with your PCB manufacturer to validate material choices based on their fabrication capabilities and experience with similar projects. Testing prototypes under real-world conditions can also confirm whether the selected material meets performance expectations.

Conclusion: Making an Informed Decision for Home Appliance PCBs

Understanding PCB materials is the foundation of designing reliable and efficient control boards for home appliances. Whether you opt for the versatility of FR-4 materials for home appliance PCBs, the affordability of CEM-1 materials for home appliance PCBs, or the specialized benefits of high-temperature, flexible, or metal core PCB materials for home appliances, each choice comes with trade-offs in cost, performance, and suitability.

By carefully comparing different PCB materials for home appliance applications and considering factors affecting PCB material selection for home appliances, you can ensure your design meets both technical and economic goals. A well-chosen substrate not only enhances the appliance’s functionality but also extends its lifespan, delivering value to both manufacturers and end-users.

ALLPCB

ALLPCB