Are you struggling with PCB silkscreen color problems like fading, bleeding, or inconsistency? These issues can impact the readability and professionalism of your printed circuit boards (PCBs), making assembly and troubleshooting harder. In this practical guide, we’ll walk you through the common causes of silkscreen color issues and provide actionable solutions for troubleshooting and repair. Whether you’re dealing with silkscreen color fading, bleeding, or inconsistency, we’ve got you covered with tips to ensure clear and durable markings on your boards.

At ALLPCB, we understand the importance of high-quality silkscreen printing for your projects. Let’s dive into this comprehensive guide to help you resolve PCB silkscreen color problems and achieve professional results every time.

What Are PCB Silkscreen Color Issues?

PCB silkscreen refers to the layer of text and symbols printed on a circuit board to label components, indicate test points, and provide assembly instructions. Typically made from non-conductive epoxy ink, silkscreen markings are essential for functionality and ease of use. However, when silkscreen color problems occur—such as fading, bleeding, or inconsistency—it can lead to misidentification of parts or assembly errors.

Common PCB silkscreen color issues include:

- Silkscreen Color Fading: Markings lose their vibrancy over time due to environmental factors or poor ink quality.

- Silkscreen Color Bleeding: Ink spreads beyond its intended boundaries, creating blurry or unreadable text.

- Silkscreen Color Inconsistency: Uneven color application across the board, making some markings darker or lighter than others.

These problems can arise from various factors, including manufacturing processes, material choices, and environmental exposure. In the sections below, we’ll explore the root causes and offer practical troubleshooting tips to address these issues.

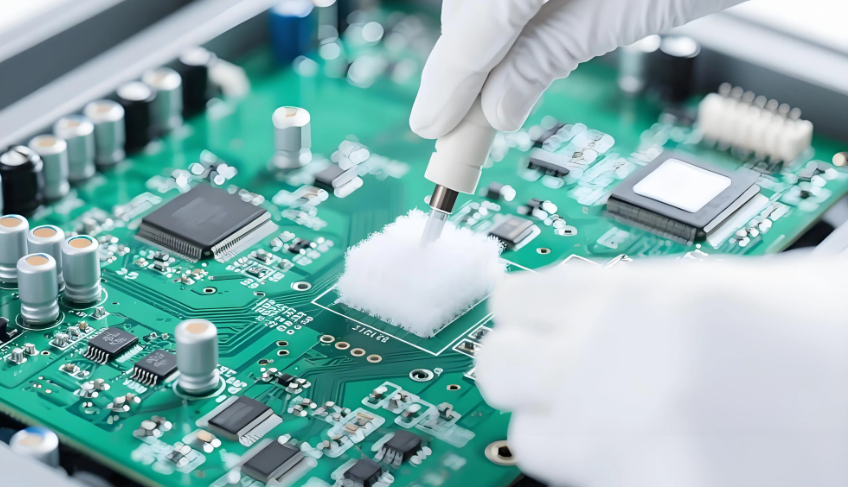

Suggested Image Placement:

Why Do PCB Silkscreen Color Problems Happen?

Understanding the causes of silkscreen color issues is the first step in troubleshooting them. Let’s break down the most common reasons for silkscreen color fading, bleeding, and inconsistency.

1. Poor Ink Quality or Compatibility

The ink used for silkscreen printing must be specifically formulated for PCB applications. If the ink is of low quality or incompatible with the board’s surface material, it may not adhere properly. This can result in silkscreen color fading over time or bleeding during the curing process. For instance, using an ink not designed for high-temperature soldering processes can cause it to break down or smear.

2. Incorrect Curing Process

After printing, silkscreen ink needs to be cured at specific temperatures (often between 120°C and 150°C for 30-60 minutes, depending on the ink type) to ensure durability. If the curing temperature is too low or the duration is insufficient, the ink may not set properly, leading to fading or peeling. Conversely, overheating can cause the ink to crack or bleed.

3. Environmental Exposure

PCBs are often exposed to harsh conditions like humidity, UV light, or chemicals during operation or storage. Over time, these factors can degrade the silkscreen layer, causing color fading. For example, prolonged exposure to UV light can break down the pigments in the ink, reducing its opacity by up to 30% within a few months under direct sunlight.

4. Surface Preparation Issues

Before silkscreen printing, the PCB surface must be clean and free of contaminants like dust, oil, or residues. If the surface isn’t properly prepared, the ink may not bond well, leading to silkscreen color inconsistency or peeling. This is especially common when manufacturing processes skip critical cleaning steps.

5. Printing Technique Errors

The method used to apply silkscreen ink—whether manual screen printing, liquid photo imaging, or direct legend printing—can also affect the outcome. For instance, uneven pressure during manual printing can cause silkscreen color bleeding, while misaligned stencils can result in inconsistent markings.

Troubleshooting PCB Silkscreen Color Issues

Now that we’ve identified the causes of PCB silkscreen color problems, let’s explore practical troubleshooting steps to resolve issues like silkscreen color fading, bleeding, and inconsistency. These tips are designed to help engineers and manufacturers pinpoint problems and implement effective solutions.

Step 1: Inspect the Ink Quality and Type

Start by reviewing the ink used for silkscreen printing. Ensure it’s a high-quality, non-conductive epoxy ink designed for PCB applications. Check the manufacturer’s specifications to confirm compatibility with your board material (e.g., FR-4, aluminum, or flexible substrates) and soldering processes. If the ink isn’t suitable, switch to a recommended product with better adhesion and durability properties.

Step 2: Verify the Curing Process

Examine the curing parameters used during manufacturing. Cross-check the temperature and duration against the ink manufacturer’s guidelines. For example, if the ink requires curing at 140°C for 45 minutes but was only cured at 100°C for 20 minutes, this could explain silkscreen color fading or peeling. Adjust the curing process to meet the recommended conditions, and consider using a calibrated oven for consistent results.

Step 3: Test for Environmental Damage

If silkscreen color fading is the primary issue, evaluate the environmental conditions the PCB has been exposed to. Conduct tests to measure humidity levels (ideal range: 40-60% RH) and UV exposure in the storage or operating area. If harsh conditions are unavoidable, consider using protective coatings or conformal layers over the silkscreen to shield it from degradation. Some coatings can extend the lifespan of silkscreen markings by up to 50% under harsh conditions.

Step 4: Check Surface Preparation

Inspect the PCB surface for signs of contamination before printing. Use a magnifying glass or microscope to look for oil spots, dust particles, or uneven textures. If contamination is present, implement stricter cleaning protocols, such as using isopropyl alcohol wipes or ultrasonic cleaning baths, to prepare the surface. A clean surface ensures better ink adhesion and reduces the risk of silkscreen color inconsistency.

Step 5: Evaluate Printing Techniques

Review the printing method used for silkscreen application. If manual screen printing is causing silkscreen color bleeding due to uneven pressure, consider switching to automated methods like liquid photo imaging for higher precision. Additionally, ensure that stencils or masks are properly aligned and free of defects to avoid inconsistent markings. Testing different printing techniques on a small batch of boards can help identify the most reliable approach.

How to Repair PCB Silkscreen Color Issues

If troubleshooting reveals that silkscreen color issues are already present on finished boards, repair may be necessary. While not all damage can be fully reversed, the following methods can help restore readability and functionality.

1. Touch-Up with Silkscreen Ink

For minor silkscreen color fading or inconsistency, use a fine-tip brush or marker with compatible silkscreen ink to touch up faded areas. Ensure the ink matches the original color (commonly white or black) and is rated for PCB use. Apply it carefully to avoid smudging, and cure the touched-up areas at a low temperature (around 80-100°C for 10-15 minutes) using a heat gun or small oven.

2. Apply Protective Coating

If environmental damage is causing ongoing silkscreen color fading, apply a thin layer of protective coating over the silkscreen. Clear conformal coatings, such as acrylic or silicone-based options, can shield the markings from UV light, moisture, and chemicals. Ensure the coating is evenly applied to avoid obscuring the text, and test it on a sample board to confirm compatibility with the ink.

3. Reprint the Silkscreen Layer

For severe silkscreen color bleeding or inconsistency, consider reprinting the silkscreen layer. This involves removing the damaged layer using a solvent (like acetone, applied with caution to avoid damaging the board) and reprinting the markings with a stencil or digital printing method. This process is more labor-intensive and may require professional equipment, so it’s best reserved for high-value boards or prototypes.

Preventing Future PCB Silkscreen Color Problems

Prevention is always better than repair. By taking proactive steps during design and manufacturing, you can minimize the risk of silkscreen color fading, bleeding, and inconsistency. Here are some best practices to follow:

- Choose High-Quality Materials: Opt for premium silkscreen inks and PCB substrates that are compatible with your application. Verify that the ink can withstand soldering temperatures (up to 260°C for lead-free processes) and environmental stressors.

- Optimize Curing Conditions: Stick to the recommended curing parameters for your silkscreen ink, and use precise equipment to maintain consistent temperatures and durations.

- Design for Clarity: When creating silkscreen artwork, use legible fonts (minimum size of 6 mil line width) and avoid overcrowding text near component pads to prevent bleeding during printing.

- Store PCBs Properly: Keep finished boards in a controlled environment with low humidity (below 60% RH) and minimal UV exposure to prevent premature silkscreen color fading.

- Conduct Quality Checks: Implement regular inspections during manufacturing to catch silkscreen color issues early. Use automated optical inspection (AOI) systems to detect inconsistencies with up to 99% accuracy.

Conclusion: Mastering PCB Silkscreen Color Troubleshooting

Dealing with PCB silkscreen color problems like fading, bleeding, or inconsistency can be frustrating, but with the right troubleshooting approach, you can identify and resolve these issues effectively. By inspecting ink quality, verifying curing processes, and protecting boards from environmental damage, you can ensure clear and durable silkscreen markings on every project. For cases where repair is needed, techniques like touch-up painting or reprinting can restore functionality and readability.

At ALLPCB, we’re committed to helping you achieve flawless PCB designs and manufacturing outcomes. By following the practical tips in this guide, you’ll be well-equipped to tackle silkscreen color issues and prevent them from happening in the future. Whether you’re a seasoned engineer or new to PCB design, these strategies will help you maintain professional, high-quality boards every time.

Remember, consistent attention to detail during design, manufacturing, and storage is key to avoiding silkscreen color problems. With these tools in hand, you’re ready to troubleshoot and repair with confidence.

ALLPCB

ALLPCB