In the world of retail displays, effective thermal management in printed circuit boards (PCBs) is critical to ensure the longevity and performance of LED systems. If you're searching for solutions related to retail display PCB thermal design, LED PCB heat dissipation, or PCB cooling techniques for retail displays, you're in the right place. This blog post will guide you through the importance of thermal management, the challenges of heat in retail display PCBs, and practical strategies to keep your LEDs running cool and efficiently.

Retail displays often rely on LEDs for vibrant, eye-catching visuals. However, LEDs generate heat, and without proper cooling, this heat can degrade performance, reduce lifespan, and even cause system failures. In this comprehensive guide, we'll explore actionable techniques to manage heat in retail display PCBs, ensuring your displays remain bright and reliable for years to come.

Why Thermal Management Matters in Retail Display PCBs

Thermal management is the process of controlling the heat generated by electronic components to maintain optimal operating conditions. In retail display PCBs, where LEDs are densely packed to create stunning visual effects, heat buildup is a common issue. Excessive heat can lead to color shifts in LEDs, reduced brightness, and even complete failure of the display system. For businesses, this translates to higher maintenance costs and potential downtime—something no retailer wants.

LEDs typically operate best at junction temperatures below 85°C. When temperatures exceed this threshold, their efficiency drops, and their lifespan can be reduced by up to 50% for every 10°C increase. Effective thermal design in retail display PCBs isn’t just a technical requirement; it’s a business necessity to protect your investment and maintain customer engagement through flawless displays.

Understanding Heat Challenges in Retail Display PCBs

Retail display PCBs face unique thermal challenges due to their environment and design constraints. Let’s break down the primary sources of heat and why they’re problematic:

- High LED Density: Retail displays often pack numerous LEDs into a small area to achieve high brightness and resolution. This density generates significant heat in a confined space, making dissipation difficult.

- Enclosed Environments: Many retail displays are housed in enclosures or cabinets with limited airflow, trapping heat and causing temperature spikes.

- Continuous Operation: Displays in stores or malls often run for 12–24 hours daily, leaving little time for components to cool down naturally.

- Ambient Conditions: Retail environments can vary widely in temperature and humidity, adding stress to PCB components if not designed with thermal resilience in mind.

Without addressing these challenges through proper retail display PCB thermal design, the risk of overheating becomes a constant concern. Overheating not only affects LEDs but also impacts other components like drivers and power supplies, leading to system-wide failures.

Key Principles of LED PCB Heat Dissipation

Before diving into specific cooling techniques, it’s important to understand the basic principles of heat dissipation in LED PCBs. Heat moves from hotter to cooler areas through three main mechanisms: conduction, convection, and radiation. In retail display PCBs, the goal is to efficiently transfer heat away from LEDs and other heat-generating components to prevent damage.

Conduction involves heat moving through solid materials, such as from an LED to a PCB substrate. Convection occurs when heat is carried away by air or liquid flow around the PCB. Radiation, though less significant in most PCB designs, refers to heat emitted as infrared energy. Effective LED PCB heat dissipation relies on optimizing these mechanisms through material selection, layout design, and cooling solutions.

For instance, the thermal conductivity of a PCB substrate plays a major role. Standard FR-4 material has a thermal conductivity of about 0.3 W/m·K, which is insufficient for high-power LED applications. In contrast, metal-core PCBs (MCPCBs), often made with aluminum, offer thermal conductivity values of 1–2 W/m·K or higher, making them a popular choice for retail display designs.

Effective PCB Cooling Techniques for Retail Displays

Now that we’ve covered the basics, let’s explore practical PCB cooling techniques for retail displays. These strategies are designed to tackle heat at multiple levels, from material choices to active cooling systems.

1. Use of Metal-Core PCBs (MCPCBs) for Enhanced Conductivity

Metal-core PCBs are a go-to solution for LED-based retail displays due to their superior thermal conductivity. By using a metal base layer, typically aluminum or copper, MCPCBs efficiently conduct heat away from LEDs to a larger surface area where it can dissipate. This reduces the junction temperature of LEDs, often keeping it below the critical 85°C mark even under heavy loads.

In practical terms, an MCPCB with a 1.6mm aluminum base can handle heat dissipation for LED arrays with power densities up to 5 W/in2, making it ideal for high-brightness retail displays. When designing with MCPCBs, ensure proper mounting to a heat sink or enclosure for maximum effect.

2. Optimizing PCB Layout for Heat Distribution

The layout of a PCB can significantly impact its thermal performance. Place heat-generating components, like LEDs and power regulators, in areas with good access to cooling mechanisms. Avoid clustering high-power components together, as this creates hot spots. Instead, distribute them evenly across the board to balance heat distribution.

Additionally, incorporate thermal vias—small holes filled with conductive material—around LED mounting points. These vias transfer heat from the top layer of the PCB to the bottom or inner layers, where it can be dissipated more effectively. A typical design might include 10–15 thermal vias per high-power LED, each with a diameter of 0.3mm, to ensure adequate heat transfer.

3. Integrating Heat Sinks for Passive Cooling

Heat sinks are a simple yet effective passive cooling solution for retail display PCBs. These metal structures, often made of aluminum due to its high thermal conductivity (around 200 W/m·K), absorb heat from the PCB and release it into the surrounding air through convection. Heat sinks are particularly useful in enclosed displays where airflow is limited.

For retail applications, consider low-profile heat sinks to fit within space constraints. Ensure a tight thermal interface between the PCB and heat sink using thermal interface materials (TIMs) like thermal paste or pads, which can improve heat transfer efficiency by up to 30%.

4. Implementing Active Cooling with Fans or Liquid Systems

In high-power retail displays where passive cooling isn’t enough, active cooling systems like fans or liquid cooling can step in. Small, low-noise fans can be integrated into display enclosures to force air circulation, reducing ambient temperatures around the PCB by 10–20°C. When selecting fans, prioritize those with a high airflow-to-noise ratio, as retail environments require quiet operation.

Liquid cooling, though less common due to cost and complexity, offers superior heat dissipation for extremely high-density LED displays. These systems use a coolant fluid to absorb and transfer heat away from the PCB, maintaining temperatures even under continuous operation. While liquid cooling can be overkill for most retail displays, it’s worth considering for outdoor or large-scale installations exposed to harsh conditions.

5. Selecting Thermal Interface Materials (TIMs) for Better Heat Transfer

Thermal interface materials bridge the gap between heat-generating components and cooling solutions like heat sinks. TIMs, such as thermal grease or silicone pads, fill microscopic air gaps that hinder heat transfer, improving thermal conductivity by up to 5 W/m·K in some cases. For retail display PCBs, choose TIMs with high durability to withstand long-term use without degrading.

Apply TIMs in a thin, even layer—typically 0.1mm thick—to avoid excess material that can act as an insulator rather than a conductor. This small detail can make a big difference in maintaining low junction temperatures for LEDs.

Design Considerations for Retail Display PCB Thermal Management

Beyond specific cooling techniques, a holistic approach to retail display PCB thermal design involves several key considerations during the design phase. These steps help prevent thermal issues before they arise:

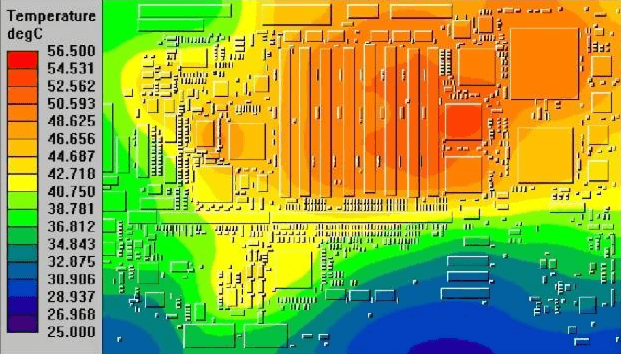

- Simulation and Testing: Use thermal simulation software to model heat flow in your PCB design before manufacturing. Tools can predict hot spots and guide layout adjustments, saving time and cost. Aim for a design where no component exceeds 80% of its maximum operating temperature during simulations.

- Component Selection: Choose LEDs and drivers with high thermal tolerance and efficiency. For example, opt for LEDs with a thermal resistance of less than 5°C/W to minimize heat generation.

- Enclosure Design: Design display enclosures with ventilation slots or mesh panels to promote natural airflow. Even small openings can reduce internal temperatures by 5–10°C.

- Power Management: Reduce heat by optimizing power delivery to LEDs. Use pulse-width modulation (PWM) dimming to lower power consumption during low-brightness periods, cutting heat output by up to 20%.

Benefits of Effective Thermal Management in Retail Displays

Investing in proper thermal management for retail display PCBs offers several long-term benefits. First, it extends the lifespan of LEDs, often doubling their operational life from 25,000 to 50,000 hours or more when temperatures are kept in check. This reduces replacement costs and downtime for maintenance.

Second, consistent thermal performance ensures uniform brightness and color accuracy across the display, enhancing the customer experience. A display that dims or shifts color due to heat can detract from your brand image. Finally, energy efficiency improves as cooler components draw less power to maintain performance, potentially lowering electricity costs by 10–15% over time.

Common Mistakes to Avoid in Thermal Design

Even with the best intentions, thermal design errors can compromise retail display performance. Here are some pitfalls to steer clear of:

- Ignoring Ambient Conditions: Failing to account for the store environment, such as high humidity or temperature swings, can render cooling solutions ineffective.

- Overloading PCBs: Packing too many LEDs or components into a small area without adequate cooling creates unavoidable hot spots.

- Skipping Thermal Testing: Not testing the PCB under real-world conditions before deployment can lead to unexpected failures. Always validate designs with thermal stress tests.

- Using Low-Quality Materials: Opting for cheaper substrates or TIMs may save costs upfront but will lead to poor heat dissipation and early component failure.

Conclusion: Building Cooler, More Reliable Retail Displays

Thermal management is a cornerstone of designing effective retail display PCBs. By prioritizing LED PCB heat dissipation and implementing proven PCB cooling techniques for retail displays, you can ensure your displays remain vibrant, reliable, and cost-effective over time. From selecting high-conductivity materials like MCPCBs to integrating heat sinks and optimizing layouts, every step in retail display PCB thermal design plays a role in keeping LEDs cool.

At ALLPCB, we’re committed to supporting your retail display projects with high-quality PCB solutions tailored for thermal performance. Whether you’re designing a small in-store sign or a large outdoor billboard, these strategies will help you tackle heat challenges head-on, delivering stunning visuals that stand the test of time.

ALLPCB

ALLPCB