In today’s fast-paced electronics industry, sustainability is no longer just a buzzword—it’s a necessity. Flexible Printed Circuit Boards (Flex PCBs) are at the heart of many modern devices, from wearable tech to medical equipment. But how can we design these critical components to last longer and minimize environmental impact? At ALLPCB, we’re committed to eco-friendly solutions. This blog dives deep into sustainable Flex PCB design, focusing on flexible PCB lifespan extension, durable flex PCB materials, flex PCB recycling methods, minimizing waste in flex PCB design, and eco-friendly flex PCB manufacturing. Let’s explore how to create Flex PCBs that stand the test of time while reducing e-waste.

Why Sustainability Matters in Flex PCB Design

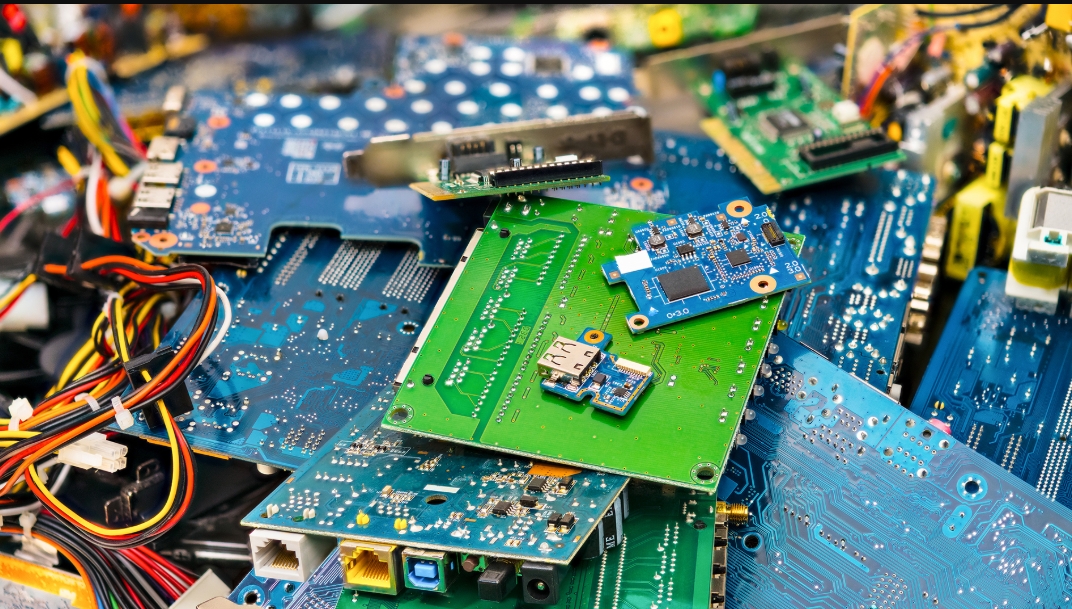

The electronics industry generates millions of tons of e-waste every year. According to a 2020 report by the Global E-waste Statistics Partnership, the world produced 53.6 million metric tons of e-waste, with only 17.4% being recycled. Flex PCBs, due to their complex materials and compact designs, often contribute to this growing problem. Designing for sustainability not only helps reduce waste but also lowers production costs over time and meets increasing regulatory demands for greener practices. By focusing on longevity and recyclability, we can make a significant impact on the environment while delivering high-quality products.

Key Strategies for Flexible PCB Lifespan Extension

Extending the lifespan of Flex PCBs is a cornerstone of sustainable design. A longer-lasting board means fewer replacements, reduced waste, and lower costs for manufacturers and end-users. Here are some proven strategies to achieve flexible PCB lifespan extension.

1. Optimize Design for Stress Resistance

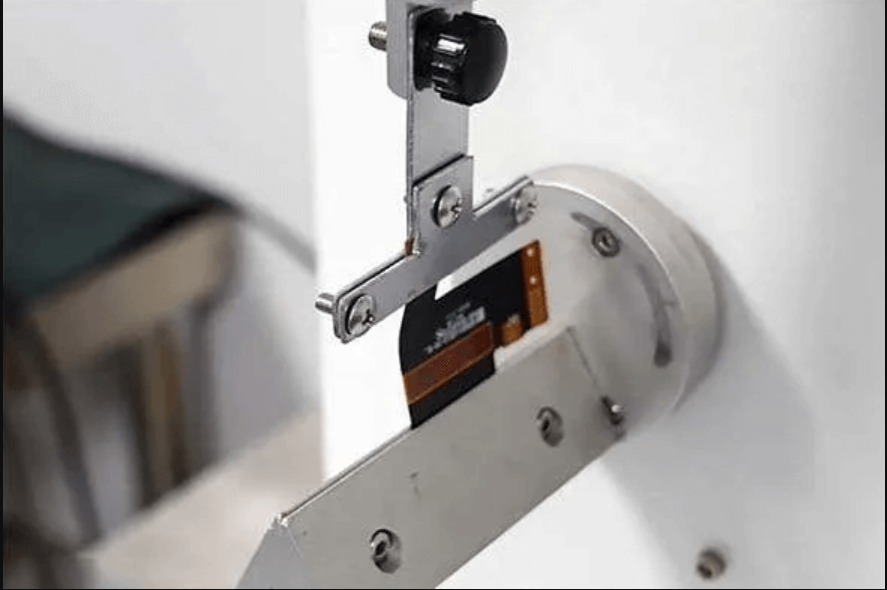

Flex PCBs are often subjected to bending, twisting, and environmental stress. Poor design can lead to cracks or delamination, shortening the board’s life. To counter this, designers should focus on minimizing stress points by using rounded corners instead of sharp angles in trace layouts. Additionally, placing critical components away from high-flex areas can prevent mechanical failure. Simulation tools can predict stress distribution, allowing for designs that withstand up to 100,000 flex cycles without degradation.

2. Use Protective Coatings

Environmental factors like moisture, dust, and chemicals can degrade Flex PCBs over time. Applying conformal coatings, such as silicone or acrylic, can protect against these hazards. These coatings can extend the board’s life by up to 50% in harsh conditions, ensuring reliability in applications like automotive or outdoor electronics.

3. Test for Durability

Rigorous testing, such as thermal cycling and bend testing, helps identify weaknesses early in the design phase. For instance, subjecting a Flex PCB to temperatures ranging from -40°C to 85°C over 1,000 cycles can simulate years of real-world use. This data allows engineers to refine designs for maximum durability.

Choosing Durable Flex PCB Materials

The materials used in Flex PCBs play a huge role in their longevity and environmental impact. Selecting durable flex PCB materials ensures the board can handle repeated use while also considering sustainability. Here’s what to look for.

1. High-Quality Base Materials

Polyimide is the go-to material for Flex PCBs due to its excellent thermal stability and flexibility. It can withstand temperatures up to 400°C and offers a tensile strength of around 165 MPa, making it ideal for demanding applications. Choosing high-grade polyimide over cheaper alternatives can double the lifespan of a Flex PCB.

2. Lead-Free and Non-Toxic Options

Traditional PCB materials often contain hazardous substances like lead or halogenated flame retardants. Switching to lead-free solders and halogen-free laminates not only complies with regulations like RoHS (Restriction of Hazardous Substances) but also reduces environmental harm during disposal. These materials maintain performance, with lead-free solders supporting signal integrity at frequencies up to 10 GHz.

3. Recyclable Substrates

Emerging bio-based substrates, such as those made from cellulose or other organic compounds, are gaining attention for their recyclability. While not yet as common as polyimide, these materials can reduce the carbon footprint of Flex PCB production by up to 30%, based on lifecycle assessments from recent industry studies.

Flex PCB Recycling Methods: Closing the Loop

Recycling is a critical part of reducing e-waste, but Flex PCBs pose unique challenges due to their layered construction and mixed materials. Implementing effective flex PCB recycling methods can recover valuable resources and minimize landfill contributions. Here are some approaches.

1. Mechanical Recycling

This method involves physically separating materials like copper, plastics, and adhesives through shredding and sorting. Up to 90% of copper can be recovered from Flex PCBs using mechanical processes, which can then be reused in new boards. However, care must be taken to avoid contamination during separation.

2. Chemical Recycling

Chemical processes use solvents to dissolve adhesives and separate layers, allowing for cleaner material recovery. This method can achieve a recovery rate of up to 95% for precious metals like gold and silver, often used in Flex PCB connectors. While effective, it requires strict control to prevent harmful chemical releases.

3. Design for Disassembly

Designing Flex PCBs with recycling in mind—such as using modular components or easily separable layers—makes end-of-life processing simpler. For example, avoiding permanent adhesives in favor of reversible bonding can cut disassembly time by 40%, streamlining recycling efforts.

Minimizing Waste in Flex PCB Design

Waste reduction starts at the design stage. By focusing on minimizing waste in flex PCB design, manufacturers can lower costs and environmental impact. Here are actionable tips to achieve this.

1. Optimize Layout for Material Efficiency

Efficient nesting of Flex PCB designs on manufacturing panels can reduce material waste by up to 20%. Using software to maximize panel usage ensures that less raw material, like polyimide film, goes unused. This also cuts production costs, benefiting both the environment and the bottom line.

2. Reduce Over-Engineering

Designing with only the necessary components and layers prevents excess material use. For instance, a single-layer Flex PCB might suffice for low-complexity applications, reducing material needs by 30% compared to a multi-layer design without sacrificing performance.

3. Adopt Additive Manufacturing Techniques

Traditional subtractive processes, like etching, remove large amounts of material, creating waste. Additive techniques, such as inkjet printing of conductive traces, build only what’s needed, cutting waste by as much as 50% in some cases. This method also supports precise impedance control, maintaining signal integrity at levels like 50 ohms for high-speed applications.

Eco-Friendly Flex PCB Manufacturing Practices

Manufacturing processes have a significant impact on sustainability. Adopting eco-friendly flex PCB manufacturing methods can reduce energy use, emissions, and waste. Here’s how to make production greener.

1. Energy-Efficient Production

Using energy-efficient equipment and renewable energy sources can cut manufacturing emissions by up to 25%. For example, modern curing ovens with optimized heat distribution reduce energy consumption during lamination processes without compromising bond strength, which can reach 1.5 N/cm for high-quality Flex PCBs.

2. Water and Chemical Management

PCB manufacturing often involves water-intensive processes and hazardous chemicals. Implementing closed-loop water systems can reduce usage by 40%, while substituting toxic etchants with greener alternatives minimizes environmental harm. These changes also ensure compliance with strict environmental regulations.

3. Circular Economy Principles

Incorporating circular economy ideas, such as reusing scrap materials or designing for second-life applications, can transform manufacturing. For instance, offcuts from Flex PCB production can be repurposed into smaller boards or test prototypes, reducing raw material demand by up to 15%.

Benefits of Sustainable Flex PCB Design

Designing and manufacturing Flex PCBs with sustainability in mind offers multiple advantages. First, it reduces e-waste, helping to address the global challenge of electronic disposal. Second, it lowers production costs through efficient material use and energy savings. Third, it enhances brand reputation, as consumers and regulators increasingly favor environmentally responsible companies. Finally, sustainable Flex PCBs often perform better and last longer, with studies showing a 30% improvement in reliability when using high-quality, durable materials.

Challenges and Future Outlook

While sustainable Flex PCB design offers clear benefits, challenges remain. High initial costs for eco-friendly materials and processes can deter adoption, especially for smaller manufacturers. Additionally, recycling complex Flex PCBs requires advanced infrastructure, which isn’t universally available. However, innovations like biodegradable substrates and laser-induced graphene for flexible circuits are paving the way for greener electronics. Industry collaboration and government support will be key to scaling these solutions in the coming years.

Conclusion: Building a Sustainable Future with Flex PCBs

Sustainability in Flex PCB design and manufacturing is not just an option—it’s a responsibility. By focusing on flexible PCB lifespan extension, selecting durable flex PCB materials, implementing flex PCB recycling methods, minimizing waste in flex PCB design, and embracing eco-friendly flex PCB manufacturing, we can significantly reduce e-waste and create products that last. At ALLPCB, we’re dedicated to supporting engineers and manufacturers in this journey with cutting-edge solutions and expertise. Together, we can design a future where technology and sustainability go hand in hand.

ALLPCB

ALLPCB