In the world of electronics, flexible PCB boards are becoming increasingly vital for innovative designs in compact and dynamic applications. One key factor that significantly influences the performance and reliability of a flexible board application is the prepreg thickness. But what exactly is prepreg thickness, and how does it impact flexible PCB boards? Simply put, prepreg thickness refers to the layer of resin-impregnated material used in PCB manufacturing that affects flexibility, durability, and electrical performance. In this blog, we’ll dive deep into how prepreg thickness plays a crucial role in flexible PCB applications, helping engineers and designers make informed decisions for their projects.

What is Prepreg and Why Does Thickness Matter in Flexible PCB Boards?

Prepreg, short for "pre-impregnated," is a composite material made of a reinforcing fabric, like fiberglass, soaked with a resin system. In PCB manufacturing, prepreg acts as an insulating layer between copper layers, bonding them together during the lamination process. For flexible PCB boards, prepreg thickness directly influences how bendable the board is, how well it handles stress, and how it performs electrically.

In flexible board applications, where the PCB must conform to tight spaces or endure repeated bending, the thickness of the prepreg can make or break the design. A thicker prepreg layer may add rigidity, reducing flexibility, while a thinner layer enhances bendability but might compromise durability or electrical insulation. Striking the right balance is essential for ensuring the board meets the demands of its intended application, whether it’s in wearable devices, medical equipment, or automotive systems.

The Role of Prepreg Thickness in Flexible Board Applications

Flexible PCB boards are designed to bend and twist without breaking, making them ideal for applications where space and movement are critical. However, the prepreg thickness impacts several key aspects of their performance. Let’s break down these factors to understand how they affect flexible board applications.

1. Flexibility and Bend Radius

The primary advantage of a flexible PCB board is its ability to bend. Prepreg thickness plays a direct role in determining the minimum bend radius—the tightest curve the board can handle without damage. A thinner prepreg layer allows for a smaller bend radius, making the board more adaptable to compact or intricate designs. For instance, in wearable technology, where boards may need to wrap around a wrist or fit into a tiny device, a prepreg thickness of around 0.002 to 0.004 inches (50 to 100 micrometers) is often preferred for maximum flexibility.

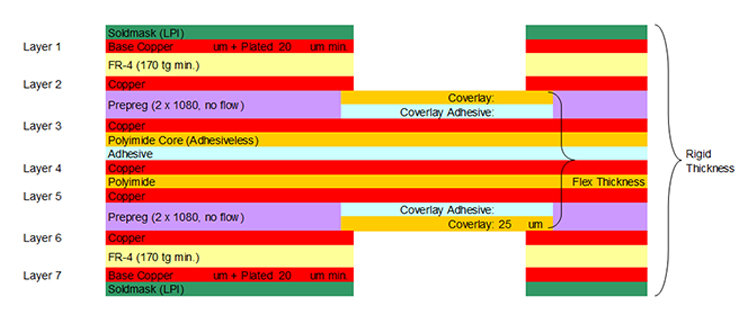

On the other hand, a thicker prepreg layer, say 0.006 inches (150 micrometers) or more, increases stiffness. While this can be useful for hybrid rigid-flex designs, it limits the board’s ability to bend tightly, potentially leading to mechanical stress or cracking over time in dynamic applications.

2. Mechanical Durability and Stress Resistance

In flexible board applications, the PCB often undergoes repeated bending or flexing, especially in devices like foldable smartphones or robotic arms. Prepreg thickness affects how well the board withstands this mechanical stress. A moderately thick prepreg layer can provide better structural integrity, distributing stress more evenly across the board and preventing cracks in the copper traces or delamination of layers.

However, if the prepreg is too thick, it can create stress concentration points during bending, leading to fatigue failure. Conversely, an overly thin prepreg might not offer enough support, causing the board to wear out quickly. Engineers often aim for a balanced thickness—commonly between 0.003 to 0.005 inches (75 to 125 micrometers)—depending on the expected flex cycles, which can range from a few hundred to over a million in high-end applications.

3. Electrical Performance and Signal Integrity

Prepreg thickness also impacts the electrical characteristics of a flexible PCB board, particularly in high-frequency applications. The thickness of the insulating layer influences the dielectric constant and impedance of the board, which are critical for maintaining signal integrity. For example, in RF (radio frequency) applications, a consistent prepreg thickness ensures controlled impedance, often targeted at 50 ohms for standard designs, to minimize signal loss and reflection.

A thinner prepreg reduces the distance between copper layers, which can increase capacitance and affect signal speed, especially at frequencies above 1 GHz. On the other hand, a thicker prepreg increases separation, potentially reducing crosstalk but also increasing the overall board thickness, which might not be ideal for ultra-thin flexible board applications. Designers must carefully calculate the required prepreg thickness based on the dielectric properties and the operating frequency of the device.

4. Thermal Management in Flexible PCB Boards

Flexible PCB boards often operate in environments where heat dissipation is a challenge due to their compact size and lack of space for traditional cooling solutions. Prepreg thickness affects how heat is transferred through the board. A thinner prepreg layer may struggle to insulate against heat, leading to hotspots that can degrade components over time. A slightly thicker prepreg can improve thermal resistance, protecting sensitive areas of the board, especially in applications like automotive electronics where operating temperatures can exceed 85°C (185°F).

However, too much thickness can trap heat, so it’s a delicate balance. Materials with specific thermal conductivity properties are often paired with the right prepreg thickness to optimize performance in high-heat flexible board applications.

Choosing the Right Prepreg Thickness for Flexible Board Applications

Selecting the appropriate prepreg thickness for a flexible PCB board depends on the specific requirements of the application. Here are some practical considerations to guide the decision-making process for engineers and designers.

Application-Specific Needs

Different flexible board applications have unique demands. For instance, in medical devices like pacemakers, the board must be extremely thin and flexible to fit within a small, curved space, often requiring prepreg thicknesses below 0.003 inches (75 micrometers). In contrast, aerospace applications might prioritize durability over flexibility, opting for a slightly thicker prepreg to withstand vibration and thermal cycling.

Material Compatibility

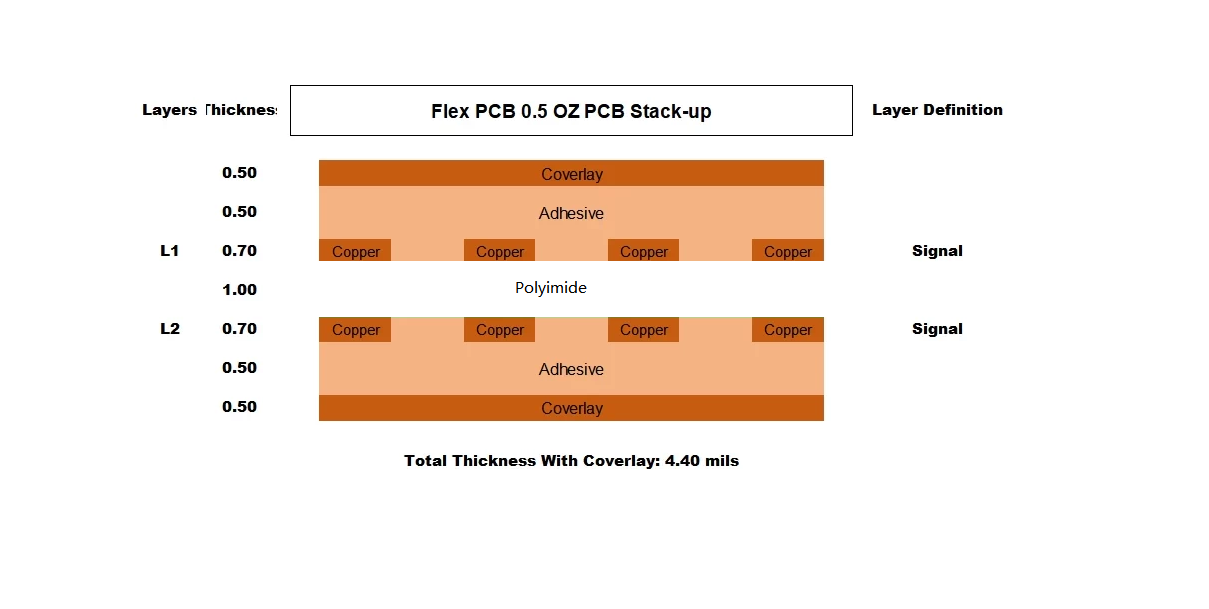

The type of prepreg material also influences the ideal thickness. Polyimide, a common material for flexible PCB boards due to its excellent thermal and mechanical stability, can be used in thinner layers without sacrificing strength. Other materials might require a thicker prepreg to achieve the same level of performance, so it’s important to align material choice with thickness specifications.

Manufacturing Constraints

The manufacturing process itself imposes limits on prepreg thickness. Very thin layers can be challenging to handle during lamination, increasing the risk of defects like voids or uneven bonding. Working with a trusted manufacturing partner ensures that the chosen prepreg thickness is feasible for production while meeting design goals.

Cost Considerations

Thinner prepreg layers often require more precise manufacturing techniques, which can drive up costs. On the other hand, thicker layers might reduce flexibility or increase material usage, also impacting the budget. Balancing performance with cost is a critical aspect of designing flexible PCB boards for any application.

Common Challenges with Prepreg Thickness in Flexible PCB Boards

While prepreg thickness offers opportunities to optimize flexible board applications, it also presents challenges that designers must address to avoid performance issues.

Delamination Risks

If the prepreg thickness is not uniform or compatible with the other layers, there’s a risk of delamination, where layers separate under stress or heat. This is particularly problematic in flexible PCB boards that undergo constant bending. Ensuring consistent thickness and proper bonding during manufacturing helps mitigate this issue.

Impedance Variability

In high-speed applications, even small variations in prepreg thickness can lead to impedance mismatches, causing signal distortion. For instance, a deviation of just 0.0005 inches (12.5 micrometers) can alter impedance by several ohms, affecting performance. Tight control over thickness tolerances is essential for maintaining reliability.

Balancing Flexibility and Strength

As mentioned earlier, achieving the right balance between flexibility and mechanical strength is a constant challenge. Over-optimizing for flexibility with an ultra-thin prepreg can compromise durability, while focusing on strength with a thicker layer can limit the board’s ability to bend. Iterative testing and simulation are often necessary to find the sweet spot.

Best Practices for Optimizing Prepreg Thickness in Flexible Board Applications

To maximize the benefits of prepreg thickness in flexible PCB boards, consider these best practices during the design and manufacturing stages.

First, use simulation tools to model how different prepreg thicknesses affect flexibility, impedance, and thermal performance before finalizing the design. These tools can predict stress points and signal behavior, reducing the need for costly prototypes.

Second, collaborate closely with material suppliers and manufacturers to select a prepreg thickness that aligns with both design goals and production capabilities. Their expertise can help identify potential issues early in the process.

Finally, prioritize testing under real-world conditions. For example, if the flexible board application involves 10,000 flex cycles, simulate this in a controlled environment to ensure the chosen prepreg thickness holds up over time.

Conclusion: The Critical Role of Prepreg Thickness in Flexible PCB Boards

Prepreg thickness is a fundamental factor in the design and performance of flexible PCB boards. From determining the bend radius and mechanical durability to influencing electrical performance and thermal management, the right thickness can significantly enhance the success of a flexible board application. By carefully considering the specific needs of the application, material properties, and manufacturing constraints, engineers can optimize prepreg thickness to create reliable, high-performing flexible PCBs for a wide range of industries.

Whether you’re designing for wearable tech, medical devices, or automotive systems, understanding the impact of prepreg thickness empowers you to make informed choices that balance flexibility, strength, and cost. With the right approach, flexible PCB boards can meet the demands of even the most challenging applications, paving the way for innovative and efficient electronic solutions.

ALLPCB

ALLPCB