In the fast-evolving automotive industry, Engine Control Units (ECUs) are the brain behind vehicle performance, managing everything from fuel efficiency to emissions control. However, producing printed circuit boards (PCBs) for ECUs can be expensive due to the high standards for reliability and durability in harsh environments. So, how can manufacturers achieve cost-effective PCB manufacturing for ECUs without compromising quality? The answer lies in optimizing design, material selection, and production processes.

In this comprehensive guide, we’ll explore proven techniques for reducing costs in ECU PCB production. From low-cost PCB design strategies to innovative manufacturing methods, we’ll provide actionable insights to help automotive engineers and manufacturers save money while maintaining the highest standards. Let’s dive into the world of automotive PCB cost reduction and efficient production.

What Makes ECU PCB Production Expensive?

Before we discuss cost-saving techniques, it’s important to understand why ECU PCB production can be costly. ECUs operate in extreme conditions, including high temperatures, vibrations, and humidity, often found under the hood of a vehicle. These factors demand specialized materials, rigorous testing, and precise manufacturing, all of which drive up costs.

- High-Quality Materials: Automotive PCBs often use substrates with excellent thermal resistance, like ceramic-based or high-grade organic resin materials, to withstand temperatures up to 150°C.

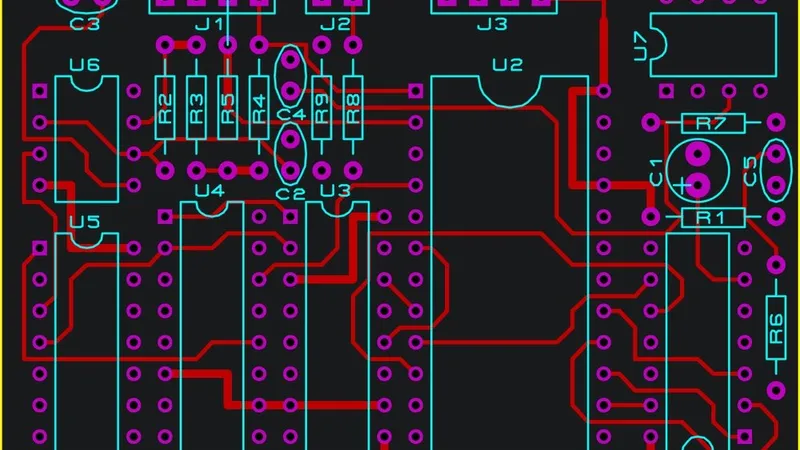

- Complex Designs: ECUs require multi-layer boards to accommodate dense circuits, increasing design and fabrication complexity.

- Strict Standards: Compliance with automotive standards like ISO/TS 16949 and AEC-Q100 adds testing and certification expenses.

- Durability Needs: PCBs must resist mechanical stress and corrosion, often requiring additional protective coatings or conformal layers.

With these challenges in mind, let’s explore cost-effective PCB manufacturing techniques tailored for ECU production.

Key Strategies for Cost-Effective PCB Manufacturing in ECU Production

1. Optimize PCB Design for Cost Efficiency

One of the most impactful ways to reduce automotive PCB cost is through low-cost PCB design practices. A well-thought-out design minimizes material waste, simplifies manufacturing, and reduces errors during production.

- Minimize Layer Count: While ECUs often need multi-layer boards (4 to 8 layers or more), reducing unnecessary layers can save costs. For instance, consolidating signal routing to fewer layers can lower fabrication expenses by 10-15% per board.

- Use Standard Component Sizes: Opt for widely available, standard-sized components instead of custom parts. This reduces procurement costs and avoids delays. For example, using 0805 or 0603 resistors instead of non-standard sizes can cut component costs by up to 20%.

- Simplify Trace Layouts: Avoid overly complex trace patterns. Wider traces (e.g., 6-8 mils for power lines) and larger vias (e.g., 12 mils) are easier to manufacture and reduce defect rates, saving on rework costs.

- Panelization: Design PCBs to fit efficiently on standard panel sizes (e.g., 18x24 inches). Proper panelization can increase yield per panel by 30%, lowering per-unit costs.

By focusing on these design principles, manufacturers can achieve significant savings in ECU PCB production without sacrificing performance.

2. Select Cost-Effective Materials Without Compromising Quality

Material selection plays a critical role in balancing cost and performance in automotive PCB production. While high-end materials ensure reliability, there are ways to choose cost-effective options that still meet automotive standards.

- FR-4 as a Base Material: For non-extreme applications, standard FR-4 laminates with a glass transition temperature (Tg) of 130-140°C can be used instead of more expensive high-Tg materials (170°C or above). This can reduce material costs by 15-25%.

- Hybrid Material Use: Combine ceramic-based substrates for high-heat areas (near engine sensors) with organic resin-based materials for less critical sections. This hybrid approach can cut material expenses by up to 20% compared to full ceramic boards.

- Thinner Copper Layers: Use thinner copper layers (e.g., 1 oz instead of 2 oz) for non-power-intensive circuits. This reduces raw material costs by approximately 10% while still meeting signal integrity needs for most ECU applications.

Balancing material performance with cost is essential for low-cost PCB design, especially in high-volume automotive production.

3. Leverage Advanced Manufacturing Techniques

Modern PCB manufacturing techniques can significantly lower costs by improving efficiency and reducing waste. Here are some methods to consider for ECU PCB production:

- Automated Assembly: Automated pick-and-place machines can reduce labor costs by 30-40% compared to manual assembly. They also improve placement accuracy, minimizing errors in high-density ECU boards.

- Additive Manufacturing: Unlike traditional subtractive methods that etch away excess copper, additive processes deposit conductive material only where needed. This can reduce material waste by up to 25%, lowering overall production costs.

- Batch Production: Producing ECUs in larger batches optimizes machine setup times and reduces per-unit costs. For example, manufacturing 10,000 units in a single run can decrease costs by 15% compared to smaller runs of 1,000 units.

- In-House Testing: Conducting basic functional and environmental testing in-house (e.g., thermal cycling from -40°C to 125°C) instead of outsourcing can save up to 20% on validation costs.

These manufacturing techniques streamline production and ensure cost-effective PCB manufacturing for automotive applications.

4. Focus on Thermal Management to Avoid Costly Failures

Thermal management is critical for ECU PCBs due to the high operating temperatures in automotive environments. Poor heat dissipation can lead to failures, costly repairs, or redesigns. Implementing cost-effective thermal solutions during design and manufacturing can prevent these issues.

- Thermal Vias: Add thermal vias under heat-generating components like power transistors to transfer heat to a ground plane or heat sink. This low-cost solution (adding less than 5% to board cost) can extend component life by reducing operating temperatures by 10-15°C.

- Heat Sinks: Use lightweight aluminum heat sinks instead of more expensive copper ones. Aluminum heat sinks cost 30-40% less and still provide adequate cooling for most ECU applications.

- Strategic Component Placement: Place high-heat components away from sensitive circuits and near board edges for better airflow. This design tweak costs nothing but can reduce thermal stress significantly.

Effective thermal management ensures reliability without inflating automotive PCB costs, making it a key aspect of cost-effective manufacturing.

5. Streamline Supply Chain and Vendor Partnerships

A well-managed supply chain can drastically reduce costs in ECU PCB production. Building strong relationships with suppliers and optimizing procurement processes are essential for low-cost PCB design and manufacturing.

- Bulk Purchasing: Negotiate bulk discounts for raw materials like laminates and components. Buying in larger quantities can reduce costs by 10-20% per unit.

- Local Sourcing: Source materials and components from local suppliers to cut shipping costs and lead times. For instance, local sourcing can save up to 15% on logistics compared to international imports.

- Long-Term Contracts: Establish long-term agreements with trusted vendors to lock in lower prices and ensure a steady supply of materials, avoiding price fluctuations.

A streamlined supply chain directly impacts the bottom line, making it a vital part of cost-effective PCB manufacturing.

Balancing Cost and Quality in ECU PCB Production

While reducing costs is a priority, quality cannot be compromised in automotive applications. ECU failures can lead to safety risks and expensive recalls. Here’s how to maintain high standards while keeping costs low:

- Reliability Testing: Invest in essential reliability tests like thermal shock (cycling between -40°C and 125°C) and vibration testing (up to 20G) to ensure durability. These tests, while adding 5-10% to production costs, prevent costly failures in the field.

- Design for Manufacturability (DFM): Use DFM guidelines to ensure designs are easy to produce with minimal errors. For example, maintaining a minimum drill size of 0.3mm for vias reduces manufacturing defects by 15%.

- Iterative Prototyping: Create multiple low-cost prototypes before full-scale production to identify and fix design flaws early. Rapid prototyping can save up to 30% on redesign costs by catching issues before mass production.

Balancing cost and quality ensures that ECU PCBs are both affordable and reliable, meeting the strict demands of the automotive industry.

Future Trends in Cost-Effective ECU PCB Manufacturing

The automotive industry is rapidly advancing with trends like electric vehicles (EVs) and autonomous driving, which demand even more sophisticated ECUs. Staying ahead of these trends can help manufacturers further reduce costs.

- Miniaturization: Smaller, denser PCBs reduce material usage by up to 20%. Advances in microvia technology (vias smaller than 0.15mm) allow for compact designs without sacrificing functionality.

- Flexible PCBs: Flexible or rigid-flex boards can reduce assembly costs by 15% by eliminating connectors and cables in tight spaces within vehicles.

- AI-Driven Design Tools: Artificial intelligence can optimize PCB layouts for cost and performance, reducing design time by 25% and minimizing errors before production.

Adopting these emerging technologies ensures that manufacturers remain competitive in cost-effective PCB manufacturing for future automotive needs.

Conclusion: Achieving Low-Cost PCB Design for ECUs

Manufacturing Engine Control Unit PCBs doesn’t have to break the bank. By focusing on optimized designs, cost-effective materials, advanced manufacturing techniques, and efficient supply chain management, automotive manufacturers can significantly reduce costs without compromising on quality. Whether it’s minimizing layer counts, using hybrid materials, or leveraging automation, every step towards cost-effective PCB manufacturing brings savings and efficiency to ECU production.

At ALLPCB, we’re committed to helping automotive engineers and manufacturers achieve their goals with innovative and affordable PCB solutions. By implementing the strategies outlined in this guide, you can tackle the challenges of automotive PCB cost while ensuring reliability and performance in every unit. Start optimizing your ECU PCB production today and drive down costs without sacrificing excellence.

ALLPCB

ALLPCB