In the fast-evolving world of autonomous vehicles, the demand for reliable, durable, and high-performing printed circuit boards (PCBs) is higher than ever. These vehicles operate in extreme conditions, facing high temperatures, vibrations, and the need for flawless signal integrity. So, what are the best materials for PCBs in such demanding applications? Advanced PCB materials like high-Tg PCB materials, ceramic PCBs for automotive use, and high-frequency laminates are critical to meeting these challenges. In this blog, we’ll dive deep into the world of automotive PCB material selection, focusing on thermal performance PCB materials and their role in high-temperature autonomous vehicle applications.

Why Advanced PCB Materials Matter for Autonomous Vehicles

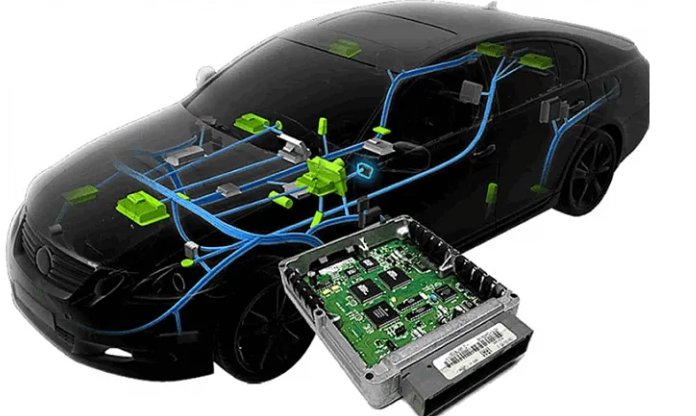

Autonomous vehicles rely on complex electronic systems for navigation, sensor processing, and real-time decision-making. These systems generate significant heat, especially in high-temperature environments like deserts or during extended operation. Without the right PCB materials, heat can degrade performance, cause failures, or even lead to safety risks. Choosing materials with excellent thermal performance and reliability ensures that the electronics can withstand harsh conditions while maintaining signal integrity for high-frequency communications.

In the sections below, we’ll explore the key materials that meet these needs, their properties, and how they contribute to the success of autonomous vehicle technology.

High-Tg PCB Materials: The Foundation for Heat Resistance

High-Tg PCB materials are a popular choice for applications where heat resistance is critical. Tg, or glass transition temperature, refers to the point at which a PCB material transitions from a rigid to a more flexible state. For autonomous vehicles, where operating temperatures can exceed 100°C, high-Tg materials (with Tg values of 170°C or higher) prevent deformation and maintain structural integrity.

These materials are typically made from advanced FR-4 laminates with enhanced resin systems. They offer improved thermal stability, making them ideal for power electronics and engine control units in automotive settings. For instance, a high-Tg material with a Tg of 180°C can handle continuous exposure to temperatures up to 150°C without losing its mechanical or electrical properties. This is crucial for autonomous vehicles operating in hot climates or under heavy computational loads.

Additionally, high-Tg PCB materials provide better resistance to thermal cycling, which occurs when a vehicle experiences repeated heating and cooling. This durability reduces the risk of delamination or cracking, ensuring long-term reliability.

Ceramic PCBs for Automotive: Unmatched Thermal Performance

When it comes to extreme heat dissipation, ceramic PCBs for automotive applications stand out. Unlike traditional FR-4 boards, ceramic PCBs use substrates like alumina (Al2O3), aluminum nitride (AlN), or beryllium oxide (BeO). These materials have exceptional thermal conductivity, often ranging from 20 to 170 W/m·K, compared to just 0.3 W/m·K for standard FR-4. This means ceramic PCBs can quickly transfer heat away from critical components, preventing overheating in high-temperature autonomous vehicle applications.

Ceramic PCBs are particularly useful in power modules and LED systems within autonomous vehicles. For example, in a LiDAR system, where high-power components generate significant heat, a ceramic substrate ensures consistent performance even at temperatures above 200°C. Moreover, these materials offer excellent mechanical strength and resistance to vibration, which are common in automotive environments.

While ceramic PCBs are more expensive than traditional options, their superior thermal performance and durability make them a worthwhile investment for critical systems in self-driving cars.

High-Frequency Laminates: Ensuring Signal Integrity

Autonomous vehicles rely on high-frequency signals for communication between sensors, cameras, and control units. Radar systems, for instance, often operate at frequencies between 24 GHz and 77 GHz. At such high frequencies, signal loss and interference become major concerns. This is where high-frequency laminates come into play.

High-frequency laminates are designed with low dielectric constants (Dk) and low dissipation factors (Df). A typical high-frequency material might have a Dk of 2.2 and a Df of 0.0009, ensuring minimal signal loss even at frequencies above 10 GHz. These properties are essential for maintaining the integrity of data transmission in autonomous vehicle systems.

Materials like PTFE (polytetrafluoroethylene) and specialized hydrocarbon-based laminates are commonly used for high-frequency applications. They also offer good thermal stability, making them suitable for the high-temperature conditions found in automotive electronics. By using high-frequency laminates, designers can achieve reliable performance for critical systems like collision avoidance and adaptive cruise control.

Automotive PCB Material Selection: Key Factors to Consider

Selecting the right material for automotive PCBs is a complex process that requires balancing multiple factors. Here are the key considerations for automotive PCB material selection, especially in high-temperature autonomous vehicle applications:

- Thermal Performance: Materials must withstand operating temperatures without degrading. For instance, power electronics near the engine might require materials that can handle up to 150°C continuously. High-Tg laminates and ceramic substrates are often the best choices here.

- Signal Integrity: For high-frequency systems, materials with low dielectric loss are essential to prevent signal degradation. A material with a dissipation factor below 0.001 is typically recommended for frequencies above 5 GHz.

- Mechanical Durability: Automotive environments involve constant vibration and shock. Materials need high tensile strength and resistance to cracking. Ceramic PCBs, for example, excel in this area due to their rigid structure.

- Cost Efficiency: While advanced materials like ceramics offer superior performance, they come at a higher cost. Designers must weigh performance needs against budget constraints, often opting for a mix of materials for different parts of the vehicle.

- Environmental Resistance: PCBs in vehicles are exposed to humidity, dust, and chemicals. Materials with good moisture resistance and low water absorption (less than 0.2%) help ensure long-term reliability.

By carefully evaluating these factors, engineers can select the most suitable materials for each component of an autonomous vehicle, optimizing performance and safety.

Thermal Performance PCB Materials: A Deeper Look

Thermal performance PCB materials are the backbone of reliable electronics in high-temperature autonomous vehicle applications. Poor thermal management can lead to component failure, reduced lifespan, and even catastrophic system breakdowns. Let’s explore how different materials address thermal challenges.

First, high-Tg materials provide a solid foundation for moderate heat resistance. They are often used in control units and infotainment systems where temperatures range from 80°C to 120°C. These materials prevent warping and maintain electrical insulation under thermal stress.

For more extreme conditions, ceramic substrates take thermal performance to the next level. With thermal conductivity values up to 170 W/m·K, they excel in dissipating heat from high-power components like motor controllers. This capability is vital in electric autonomous vehicles, where battery management systems generate significant heat during charging and operation.

Metal-core PCBs, often made with aluminum or copper bases, are another option for thermal management. They offer thermal conductivity in the range of 1-3 W/m·K, which is lower than ceramics but still effective for many automotive applications. These are commonly used in lighting systems and power converters.

Ultimately, the choice of thermal performance PCB materials depends on the specific temperature range and heat dissipation needs of the application. Combining different materials within a single vehicle design can provide a tailored solution for optimal performance.

Challenges and Future Trends in PCB Materials for Autonomous Vehicles

While advanced PCB materials have made significant strides, challenges remain. One major issue is the cost of high-performance materials like ceramics and specialized high-frequency laminates. As autonomous vehicle production scales up, finding cost-effective alternatives without compromising quality will be crucial.

Another challenge is miniaturization. As vehicle electronics become more compact, PCBs must handle higher power densities, leading to even greater heat generation. Materials with improved thermal conductivity and thinner profiles will be essential to address this trend.

Looking ahead, research into new materials like graphene-based substrates and advanced composites shows promise. These materials could offer unprecedented thermal and electrical performance, paving the way for the next generation of autonomous vehicle electronics. Additionally, the push for sustainability is driving interest in recyclable and eco-friendly PCB materials, which could reduce the environmental impact of manufacturing.

Conclusion: Building the Future with Advanced PCB Materials

The success of autonomous vehicles hinges on the reliability and performance of their electronic systems. Advanced PCB materials like high-Tg PCB materials, ceramic PCBs for automotive use, and high-frequency laminates play a vital role in meeting the demands of high-temperature environments and complex signal requirements. By focusing on automotive PCB material selection and prioritizing thermal performance PCB materials, engineers can design systems that withstand the rigors of self-driving technology.

Whether it’s ensuring heat resistance with high-Tg laminates, achieving superior heat dissipation with ceramic substrates, or maintaining signal integrity with high-frequency laminates, the right materials make all the difference. As technology continues to evolve, staying informed about the latest advancements in PCB materials will be key to building safer, more efficient autonomous vehicles.

With the right approach to material selection, the future of autonomous driving looks brighter than ever. Let’s keep pushing the boundaries of innovation to create vehicles that are not only smarter but also more resilient in the face of extreme conditions.

ALLPCB

ALLPCB