In the world of electronics manufacturing, achieving accurate PCBs is essential for ensuring reliability and performance. One of the key processes that directly impacts PCB quality is thermal profiling. But what exactly is thermal profiling, and how does it contribute to precision in PCB assembly? Simply put, thermal profiling involves monitoring and controlling the temperature changes a PCB undergoes during soldering to ensure components are bonded correctly without damage. This process is vital for maintaining reliability, managing temperature stresses, and optimizing wiring connections in PCB assembly.

In this comprehensive guide, we'll dive deep into the importance of thermal profiling, how it ensures PCB accuracy, and why it matters for temperature management and overall reliability. Whether you're an engineer, a hobbyist, or a manufacturer, understanding thermal profiling can help you produce high-quality boards that stand the test of time. Let's explore this critical aspect of PCB assembly step by step.

What Is Thermal Profiling in PCB Assembly?

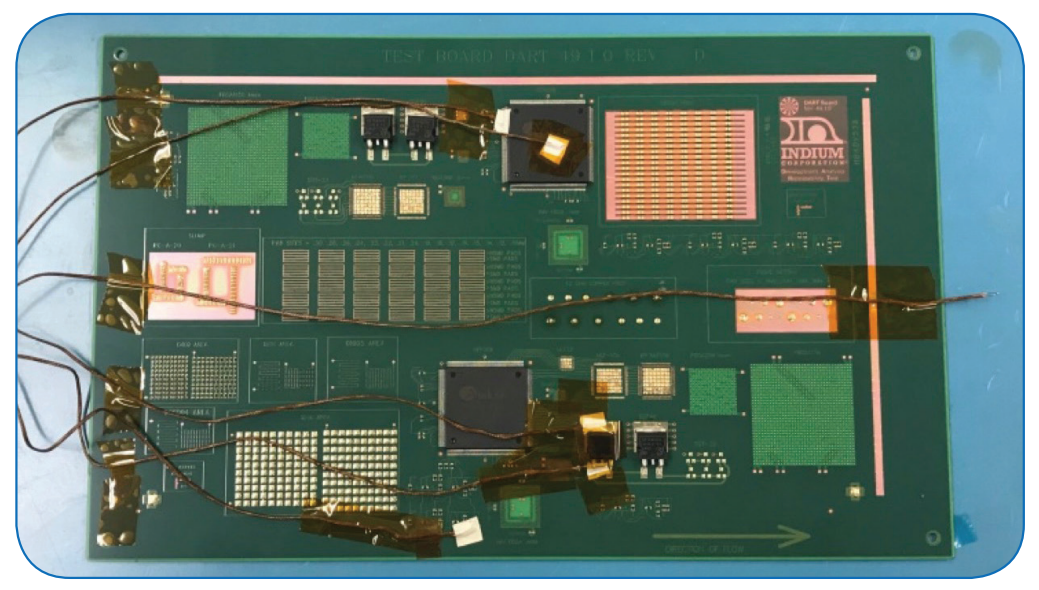

Thermal profiling is the process of measuring and recording the temperature changes a printed circuit board (PCB) experiences during the soldering process, particularly in reflow soldering. This is typically done using sensors like thermocouples attached to the board. These sensors track how the PCB heats up, cools down, and maintains temperature at various stages, ensuring that the soldering conditions are ideal for component attachment.

In PCB assembly, thermal profiling helps manufacturers create a temperature "map" or profile that matches the specific requirements of the board and its components. For instance, different components may have varying heat tolerances—some can withstand temperatures up to 260°C, while others may fail above 220°C. By tailoring the thermal profile, manufacturers can avoid issues like overheating, underheating, or thermal shock, all of which can compromise PCB accuracy and reliability.

Why Thermal Profiling Matters for Accurate PCBs

Accuracy in PCB manufacturing isn't just about precise placement of components or clean wiring—it's also about ensuring that every solder joint is formed correctly. Thermal profiling plays a pivotal role in achieving this precision. Here's why it matters:

- Prevents Component Damage: Overheating can damage sensitive components like microcontrollers or capacitors, leading to failures. A well-designed thermal profile keeps temperatures within safe limits, often between 200°C and 260°C for lead-free soldering, depending on the solder paste used.

- Ensures Strong Solder Joints: If the temperature is too low, solder may not melt properly, resulting in weak or incomplete joints. Thermal profiling ensures the solder reaches its activation temperature—typically around 217°C for lead-free alloys—for a strong bond.

- Reduces Defects: Issues like tombstoning (components lifting during soldering) or cold solder joints often occur due to uneven heating. A consistent thermal profile minimizes these defects by maintaining uniform temperature distribution across the board.

By focusing on thermal profiling, manufacturers can significantly improve the accuracy of their PCBs, ensuring that every board meets design specifications and performs reliably in real-world applications.

The Role of Temperature in PCB Reliability

Temperature management is at the heart of PCB reliability. During assembly, a PCB is exposed to rapid temperature changes, especially in the reflow oven where it undergoes heating and cooling cycles. If these temperature shifts are not controlled, they can introduce stresses that affect both the board and its components.

For example, a sudden temperature spike above 260°C can cause thermal expansion in the PCB substrate, leading to warping or delamination. Similarly, cooling too quickly can create internal stresses in solder joints, increasing the risk of cracks over time. Studies in the industry suggest that maintaining a controlled ramp-up rate of 1-3°C per second during heating can reduce thermal shock and improve long-term reliability by up to 30%.

Thermal profiling allows manufacturers to monitor and adjust these temperature changes in real time. By adhering to a carefully designed profile, they can ensure that the PCB and its wiring remain structurally sound, even under demanding conditions.

How Thermal Profiling Enhances PCB Assembly

PCB assembly is a complex process involving multiple stages, from component placement to soldering and inspection. Thermal profiling directly impacts the soldering stage, which is often the most critical for ensuring accuracy. Here's how it enhances the assembly process:

Optimizing Reflow Soldering

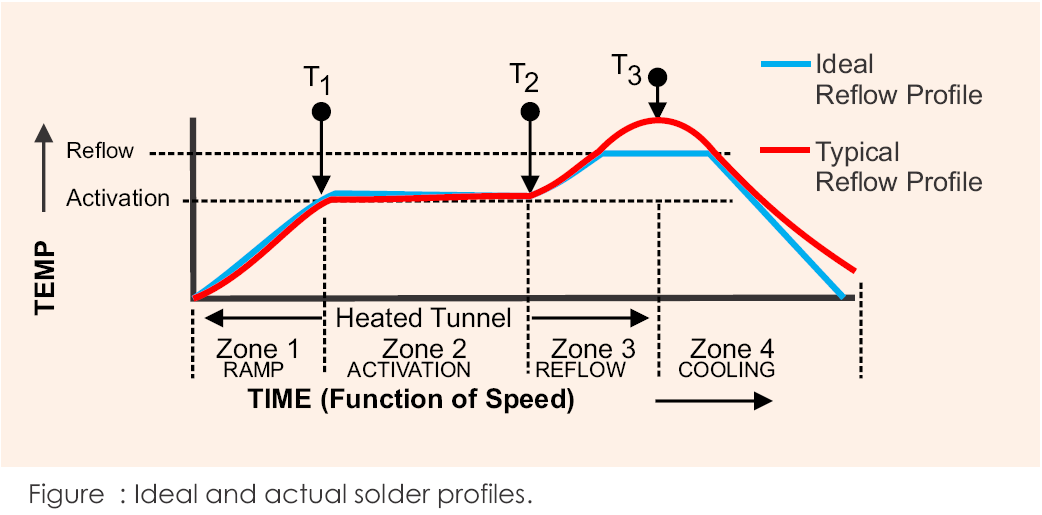

Reflow soldering, commonly used in surface-mount technology (SMT), relies on precise temperature control. A thermal profile for reflow soldering typically includes four stages:

- Preheat: The board is gradually heated to evaporate moisture and activate flux, usually between 150°C and 180°C.

- Soak: Temperature is stabilized to ensure even heat distribution, typically held at 180°C for 60-90 seconds.

- Reflow: The temperature peaks (around 235-245°C for lead-free solder) to melt the solder paste and form joints.

- Cooling: The board cools down at a controlled rate of 2-4°C per second to solidify the solder without causing thermal stress.

By following this structured profile, thermal profiling ensures that each stage is executed with precision, leading to consistent results across batches.

Supporting Complex Wiring Designs

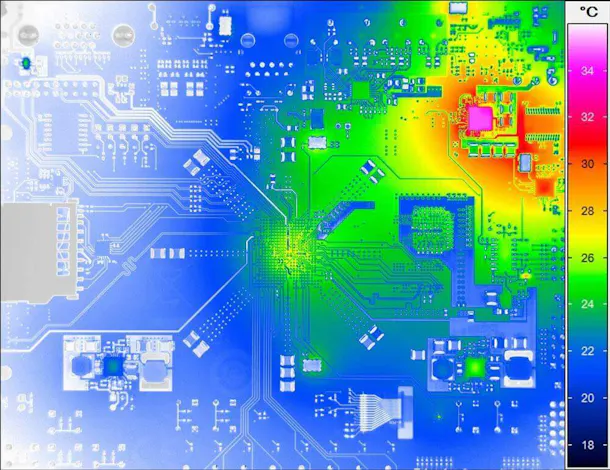

Modern PCBs often feature intricate wiring patterns with fine traces and high-density interconnects. Uneven heating during soldering can cause traces to lift or break, especially in multilayer boards where thermal conductivity varies. Thermal profiling helps by ensuring uniform heat distribution, protecting delicate wiring and maintaining signal integrity. For instance, maintaining a temperature variance of less than 5°C across the board can prevent hotspots that might damage traces as thin as 0.1 mm.

Best Practices for Effective Thermal Profiling

To achieve the best results with thermal profiling, manufacturers must follow certain best practices. These tips can help ensure PCB accuracy and reliability while addressing temperature challenges during assembly.

- Use Multiple Thermocouples: Place thermocouples at different points on the PCB, such as near large components, small components, and the board's center. This provides a complete picture of temperature distribution and helps identify potential hotspots.

- Customize Profiles for Each Design: No two PCBs are identical. Factors like board thickness, component density, and material (e.g., FR-4 or metal-core) affect heat transfer. Tailor the thermal profile to match the specific requirements of each design.

- Monitor Ramp Rates: Avoid rapid temperature changes. A ramp-up rate of 1-3°C per second during heating and a cooling rate of 2-4°C per second are generally recommended to minimize thermal stress.

- Validate Profiles Regularly: Test and validate the thermal profile with a sample board before full production. Use profiling software to analyze data and make adjustments if needed.

- Account for Lead-Free Soldering: Lead-free solder requires higher temperatures (up to 245°C) compared to traditional lead-based solder (around 220°C). Adjust the thermal profile accordingly to prevent component damage.

By adhering to these practices, manufacturers can fine-tune their thermal profiling process, ensuring that every PCB meets the highest standards of accuracy and reliability.

Challenges in Thermal Profiling and How to Overcome Them

While thermal profiling is essential for accurate PCBs, it comes with its own set of challenges. Understanding these obstacles and how to address them can make a significant difference in PCB assembly outcomes.

Uneven Heat Distribution

Large components, such as power ICs, often act as heat sinks, absorbing more heat than smaller components. This can lead to uneven heating across the board. To overcome this, place thermocouples near both large and small components to monitor temperature differences. Additionally, consider using a reflow oven with multiple heating zones for better control.

Component Sensitivity

Some components, like LEDs or electrolytic capacitors, are highly sensitive to heat and may degrade if exposed to temperatures above 230°C for too long. Check the datasheets for each component's thermal limits and adjust the profile to keep peak temperatures and durations within safe ranges.

Software and Equipment Limitations

Not all profiling tools provide real-time data or detailed analysis. Invest in advanced profiling software that can simulate thermal behavior and suggest adjustments. Pair this with a high-quality reflow oven capable of precise temperature control within ±1°C.

The Future of Thermal Profiling for PCB Accuracy

As electronics continue to evolve, so does the need for more precise thermal profiling techniques. Emerging trends like smaller components, higher-density wiring, and advanced materials (e.g., flexible substrates) are pushing the boundaries of temperature management in PCB assembly.

One exciting development is the use of virtual thermal profiling software. These tools can simulate a PCB's thermal behavior before production, allowing engineers to identify potential issues and optimize the profile without physical testing. Additionally, automation and machine learning are being integrated into reflow ovens to dynamically adjust temperatures based on real-time data, further enhancing reliability.

By staying ahead of these innovations, manufacturers can ensure that their thermal profiling processes remain effective, even as PCB designs become more complex. This not only improves accuracy but also reduces production costs and time-to-market.

Conclusion: Ensuring PCB Reliability with Thermal Profiling

Thermal profiling is a cornerstone of accurate PCB assembly, playing a critical role in managing temperature, protecting wiring, and ensuring reliability. By carefully monitoring and controlling the heating and cooling cycles during soldering, manufacturers can prevent defects, avoid component damage, and produce boards that perform consistently under various conditions.

From optimizing reflow soldering to addressing challenges like uneven heat distribution, thermal profiling offers a proven path to achieving PCB accuracy. By following best practices and embracing new technologies, you can elevate the quality of your boards and meet the demands of modern electronics applications.

At ALLPCB, we understand the importance of precision in every stage of PCB manufacturing. Our advanced thermal profiling techniques and state-of-the-art equipment are designed to deliver reliable, high-quality boards tailored to your needs. Trust us to help you achieve the accuracy and performance your projects deserve.

ALLPCB

ALLPCB