Smart eyewear, such as augmented reality (AR) glasses and smart sunglasses, relies heavily on advanced technology to deliver functionality in a compact, wearable form. At the heart of this innovation are flexible printed circuit boards (PCBs), which provide the necessary adaptability and durability for such cutting-edge devices. If you're looking to understand flexible PCB materials for smart glasses, flex PCB design rules, or the rigid-flex PCB assembly process, you've come to the right place. This guide dives deep into the world of FPC for wearable devices and explores critical aspects like bending radius for flexible PCBs, ensuring you have the knowledge to create or source the best solutions for smart eyewear.

Whether you're an engineer designing the next big thing in wearable tech or a manufacturer seeking insights into production processes, this comprehensive resource will walk you through every key detail. Let's explore the materials, design principles, and manufacturing techniques that make flexible PCBs indispensable for smart eyewear.

What Are Flexible PCBs and Why Are They Essential for Smart Eyewear?

Flexible PCBs, often referred to as FPCs (flexible printed circuits), are thin, lightweight circuit boards made from pliable materials that can bend and fold without breaking. Unlike traditional rigid PCBs, these circuits can conform to unique shapes, making them ideal for compact and curved designs like those found in smart eyewear. Their ability to save space, reduce weight, and withstand repeated bending cycles is why they are a go-to choice for FPC for wearable devices.

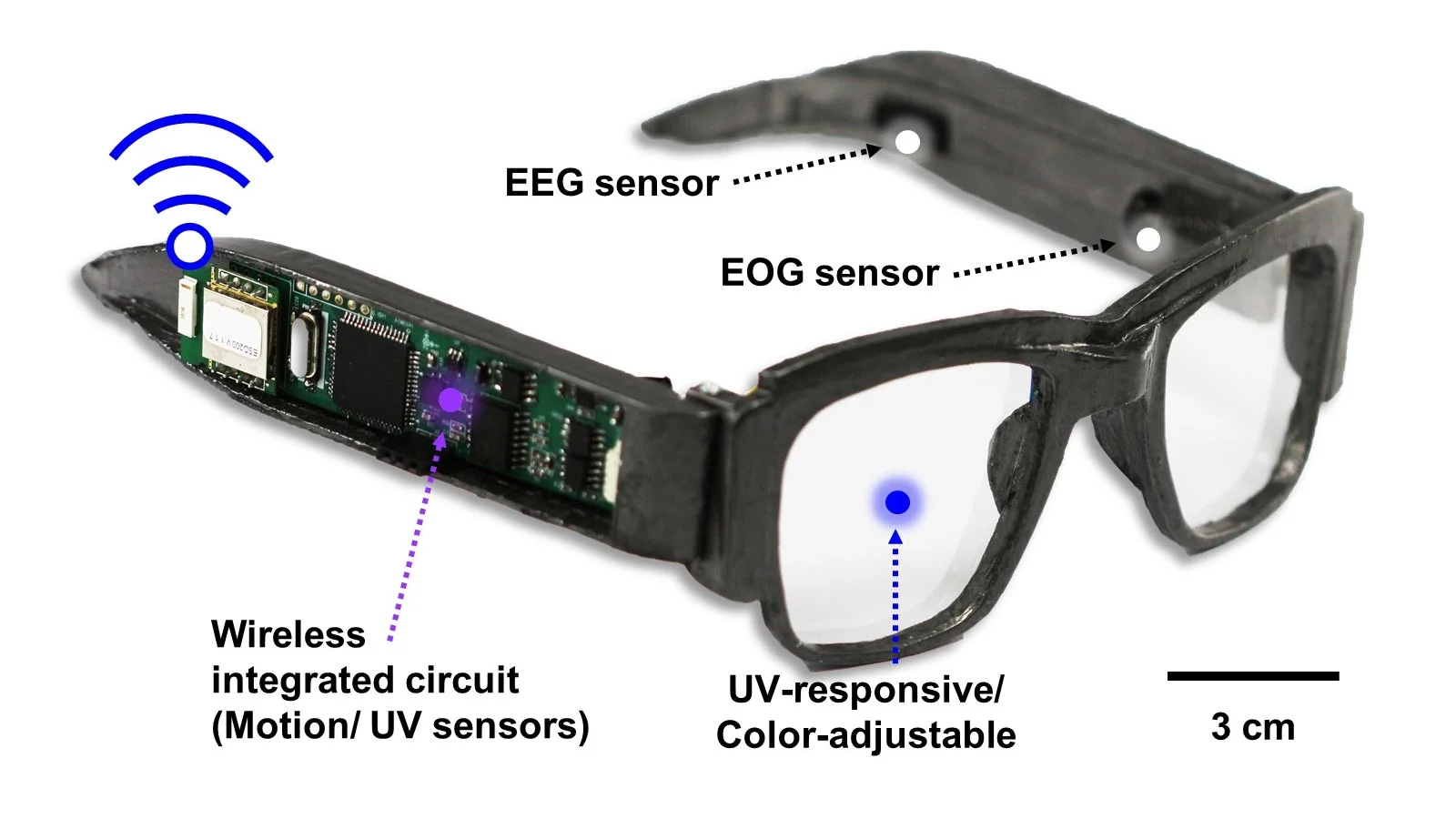

In smart eyewear, where components must fit into slim frames or curved lenses, flexible PCBs provide the connectivity needed for displays, sensors, batteries, and processors. They enable seamless integration of technology into a form factor that prioritizes user comfort and aesthetics. Without the adaptability of flexible circuits, the sleek designs of modern smart glasses would be nearly impossible to achieve.

Flexible PCB Materials for Smart Glasses: Choosing the Right Foundation

The performance and reliability of flexible PCBs in smart eyewear hinge on the materials used. Selecting the right flexible PCB materials for smart glasses involves balancing factors like flexibility, thermal resistance, and electrical performance. Below are the primary materials commonly used in these applications:

- Polyimide (PI): This is the most widely used substrate material for flexible PCBs due to its excellent thermal stability (up to 400°C) and mechanical strength. Polyimide can endure thousands of bending cycles, making it perfect for the dynamic environment of smart eyewear.

- Polyester (PET): A more cost-effective option, PET is less durable than polyimide but still offers good flexibility for static or low-bend applications. It’s often used in less demanding wearable designs.

- Copper Foil: Copper is the standard conductive material in flexible PCBs. Rolled annealed (RA) copper is preferred over electrodeposited (ED) copper because it offers better flexibility and fatigue resistance, crucial for repeated bending in smart glasses.

- Adhesives and Coverlays: Adhesives bond the layers of a flexible PCB, while coverlays (protective films) shield the circuitry. These materials must maintain flexibility and adhesion under stress to prevent delamination during use.

When designing for smart eyewear, engineers often prioritize polyimide-based materials for their durability, especially in high-end AR glasses where reliability is critical. The material choice also impacts signal integrity, with polyimide offering low dielectric loss for high-frequency applications like 5G connectivity in smart devices.

Flex PCB Design Rules: Key Guidelines for Smart Eyewear

Designing a flexible PCB for smart eyewear requires adherence to specific flex PCB design rules to ensure functionality and longevity. Poor design can lead to cracking, signal loss, or failure during bending. Here are the essential guidelines to follow:

1. Optimize for Bending Radius

The bending radius for flexible PCB is a critical parameter. A tighter bend radius increases stress on the circuit, potentially causing cracks in the copper traces. As a general rule, the minimum bend radius should be at least 10 times the thickness of the PCB for dynamic bending (repeated flexing) and 3 times the thickness for static bending (one-time installation). For a 0.1mm thick flexible PCB, this translates to a minimum dynamic bend radius of 1mm.

2. Trace Layout and Spacing

Traces should run perpendicular to the bend line to minimize stress. Avoid placing vias or components in bend areas, as they can create weak points. Maintain adequate spacing between traces—typically 0.1mm or more—to prevent short circuits during flexing.

3. Use Tear-Drop Pads

At the junction of traces and pads, use tear-drop-shaped pads instead of circular ones. This design reduces stress concentration and prevents trace cracking, especially in high-flex areas of smart eyewear frames.

4. Layer Stack-Up Considerations

For multilayer flexible PCBs, balance the stack-up to avoid uneven stress. Place the neutral axis (the plane that experiences no stress during bending) in the center of the board by using symmetrical layer arrangements. This is particularly important for smart glasses, where the PCB might wrap around curved frame components.

By following these flex PCB design rules, engineers can create reliable circuits that withstand the unique challenges of wearable tech. For instance, a well-designed FPC in smart eyewear can handle over 100,000 bend cycles without signal degradation, ensuring long-term performance.

Rigid-Flex PCB Assembly Process: Bridging Flexibility and Stability

Many smart eyewear designs incorporate rigid-flex PCBs, which combine rigid sections for mounting components with flexible sections for connectivity. The rigid-flex PCB assembly process is more complex than that of standard flexible PCBs but offers unmatched versatility for compact devices. Here's a step-by-step overview of the process:

- Material Preparation: The process begins with preparing rigid and flexible materials, typically FR4 for rigid sections and polyimide for flexible areas. These materials are laminated together using specialized adhesives that maintain flexibility in designated zones.

- Circuit Patterning: Copper layers are etched to create the circuit patterns on both rigid and flexible sections. Precision is key to ensure alignment between layers, especially in high-density designs for smart glasses.

- Drilling and Plating: Holes are drilled for vias and through-hole components, then plated with copper to establish electrical connections. Care must be taken to avoid damaging the flexible areas during this step.

- Lamination and Bonding: Multiple layers are laminated under heat and pressure. Flexible sections often require additional coverlays for protection, while rigid sections may include solder masks.

- Component Assembly: Surface-mount components are placed and soldered onto the rigid sections using automated pick-and-place machines. Flexible areas are typically left free of components to maintain bendability.

- Testing and Inspection: The assembled rigid-flex PCB undergoes electrical testing and visual inspection to detect defects like open circuits or misaligned layers. For smart eyewear, testing may include simulating bending cycles to verify durability.

The rigid-flex approach is ideal for smart eyewear because it allows stable mounting of processors and sensors on rigid areas while connecting to displays or batteries through flexible sections. This hybrid design reduces the need for additional connectors, saving space and improving reliability.

FPC for Wearable Devices: Advantages in Smart Eyewear

The use of FPC for wearable devices like smart eyewear offers several advantages over traditional rigid circuits. These benefits directly address the challenges of designing compact, user-friendly tech:

- Space Efficiency: FPCs can be folded or shaped to fit into tight spaces, such as the narrow arms of smart glasses, reducing the overall footprint of the device.

- Lightweight Design: Weighing significantly less than rigid PCBs, FPCs contribute to the comfort of wearable devices, a crucial factor for all-day use in smart eyewear.

- Durability: High-quality FPCs can endure repeated flexing without failure, ensuring that smart glasses remain functional even after extensive use.

- Reduced Interconnects: By eliminating the need for bulky connectors and cables, FPCs simplify assembly and enhance reliability, which is vital for maintaining signal integrity in high-frequency applications.

For example, in AR glasses, an FPC can connect a microdisplay in the lens area to a control unit in the frame, bending around corners without adding bulk. This seamless integration is why FPCs are a cornerstone of modern wearable technology.

Challenges and Solutions in Flexible PCB Manufacturing for Smart Eyewear

Manufacturing flexible PCBs for smart eyewear comes with unique challenges, but advancements in technology have provided effective solutions:

Challenge 1: Maintaining Signal Integrity

High-frequency signals in smart eyewear, such as those for wireless connectivity, can degrade due to the thin dielectric layers in flexible PCBs. To counter this, manufacturers use low-loss materials like modified polyimide and ensure precise impedance control, targeting values like 50 ohms for optimal performance.

Challenge 2: Ensuring Bend Durability

Repeated bending can cause fatigue in copper traces. Solutions include using rolled annealed copper and reinforcing bend areas with stiffeners or additional coverlay layers to distribute stress evenly.

Challenge 3: Miniaturization

Smart eyewear demands extremely small PCBs with high-density interconnects. Advanced manufacturing techniques, such as laser drilling for microvias (down to 0.05mm in diameter), enable the creation of compact, high-performance circuits.

By addressing these challenges, manufacturers can produce flexible PCBs that meet the stringent requirements of smart eyewear, from durability to signal speed.

Conclusion: Powering the Future of Smart Eyewear with Flexible PCBs

Flexible PCBs are the backbone of smart eyewear, enabling the sleek, lightweight, and functional designs that users demand. From selecting the right flexible PCB materials for smart glasses to adhering to flex PCB design rules and mastering the rigid-flex PCB assembly process, every step is crucial for success. Whether you're leveraging FPC for wearable devices or optimizing the bending radius for flexible PCB, understanding these elements ensures reliable and innovative products.

At ALLPCB, we’re committed to supporting engineers and manufacturers in creating cutting-edge solutions for smart eyewear and beyond. With expertise in flexible and rigid-flex PCB production, we provide the tools and resources needed to bring your designs to life. Dive into the world of flexible circuits and see how they can transform your next wearable tech project.

ALLPCB

ALLPCB