As autonomous vehicles (AVs) continue to evolve, the role of printed circuit boards (PCBs) in their control systems becomes increasingly critical. These tiny yet powerful components are the backbone of the technology that drives self-driving cars, ensuring safety, efficiency, and connectivity. In this blog, we dive deep into the future of autonomous vehicle control PCBs, exploring emerging technologies and trends such as AI-optimized PCB hardware, 5G V2X PCB technologies, sustainable PCB materials, autonomous vehicle-specific standards, and embedded passive components. Whether you're an engineer or a tech enthusiast, you'll find actionable insights into how these advancements are shaping the automotive industry.

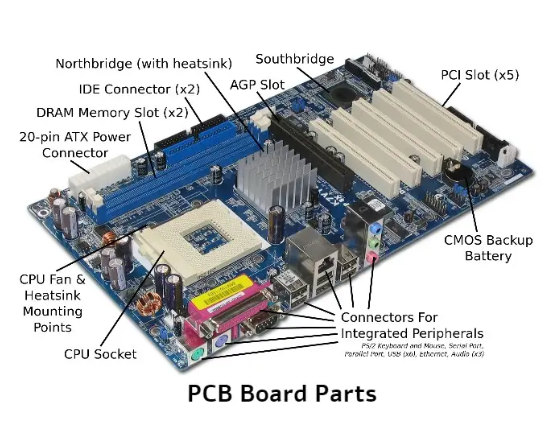

Why Are PCBs Crucial for Autonomous Vehicles?

PCBs are the heart of electronic systems in autonomous vehicles, managing everything from sensor data processing to real-time decision-making. With AVs relying on complex networks of cameras, LiDAR, radar, and other sensors, the demand for high-performance, reliable PCBs has never been higher. These boards must handle massive data loads, ensure low latency, and operate flawlessly in harsh automotive environments. As we look to the future, several key trends and technologies are set to redefine how PCBs are designed and manufactured for AV control systems.

Trend 1: AI-Optimized PCB Hardware for Smarter Vehicles

Artificial Intelligence (AI) is at the core of autonomous driving, enabling vehicles to process vast amounts of data and make split-second decisions. AI-optimized PCB hardware is emerging as a game-changer in this space. These boards are specifically designed to support high-speed processing for machine learning algorithms, which are essential for tasks like object detection, path planning, and predictive maintenance.

Modern AI-optimized PCBs often integrate high-performance processors and GPUs directly onto the board, minimizing latency and maximizing efficiency. For instance, signal processing speeds on these boards can reach up to 10 Gbps, ensuring that data from multiple sensors is analyzed in real-time. Additionally, these PCBs are built with advanced thermal management systems to handle the heat generated by intensive AI computations, often maintaining operating temperatures below 85°C even under heavy loads.

Engineers designing AI-optimized hardware for AVs focus on compact layouts to fit within tight vehicle spaces while ensuring signal integrity with impedance values typically around 50 ohms for high-speed lines. This level of precision in design helps reduce noise and ensures reliable performance, which is critical for safety in self-driving systems.

Trend 2: 5G V2X PCB Technologies for Seamless Connectivity

Vehicle-to-everything (V2X) communication is a cornerstone of autonomous driving, allowing vehicles to interact with other cars, infrastructure, pedestrians, and the cloud. The rollout of 5G technology is revolutionizing V2X systems, and 5G V2X PCB technologies are at the forefront of this transformation. These PCBs are engineered to support ultra-low latency communication, with response times as low as 1 millisecond, and data transfer rates exceeding 10 Gbps.

5G-enabled PCBs for V2X applications use advanced materials like high-frequency laminates to handle signals in the 28 GHz to 39 GHz range, ensuring minimal signal loss. They also incorporate multiple layers—sometimes up to 16 or more—to accommodate the complex circuitry needed for 5G antennas and transceivers. This allows AVs to receive real-time updates on traffic conditions, road hazards, and navigation data, enhancing safety and efficiency.

For engineers, the challenge lies in designing these PCBs to withstand electromagnetic interference (EMI) while maintaining compact sizes. Shielding techniques and precise routing of high-frequency signals are essential to achieving this balance, making 5G V2X PCB technologies a critical area of innovation for the future of AVs.

Trend 3: Sustainable PCB Materials for Eco-Friendly Manufacturing

As the automotive industry moves toward sustainability, the demand for eco-friendly manufacturing processes extends to PCB production. Sustainable PCB materials are gaining traction as a way to reduce the environmental impact of AV electronics. Traditional PCB substrates like FR-4, while cost-effective, often rely on non-recyclable materials and hazardous chemicals during production. In contrast, sustainable alternatives such as bio-based resins and halogen-free laminates are becoming more popular.

These materials not only lower the carbon footprint but also meet stringent automotive reliability standards. For example, bio-based PCB substrates can withstand temperatures up to 150°C and offer dielectric constants around 3.5, making them suitable for high-performance AV applications. Additionally, recycling programs for end-of-life PCBs are being developed to recover valuable metals like copper, which can make up to 20% of a board's weight.

By adopting sustainable PCB materials, manufacturers contribute to a greener future while meeting the growing consumer demand for environmentally responsible products. This trend is especially important as regulations around electronic waste tighten globally.

Trend 4: Autonomous Vehicle-Specific Standards for Safety and Reliability

Autonomous vehicles operate in high-stakes environments where safety is non-negotiable. This has led to the development of autonomous vehicle-specific standards for PCB design and manufacturing. Standards like ISO 26262, which focuses on functional safety for automotive electronics, are becoming the benchmark for AV control systems. These guidelines ensure that PCBs can handle critical tasks without failure, even under extreme conditions like vibrations, temperature swings from -40°C to 125°C, and humidity levels up to 95%.

Compliance with these standards requires rigorous testing, including thermal cycling and mechanical stress tests, to guarantee that PCBs maintain signal integrity and power distribution over a vehicle's lifespan, often exceeding 15 years. For engineers, adhering to these standards means selecting materials with low thermal expansion coefficients (typically below 15 ppm/°C) and designing layouts that minimize points of failure.

As AV technology advances, expect even stricter standards to emerge, pushing the boundaries of PCB design to ensure the highest levels of safety and reliability for self-driving systems.

Trend 5: Embedded Passive Components for Compact and Efficient Designs

Space is a premium in autonomous vehicles, where every component must fit within tight constraints. Embedded passive components—such as resistors, capacitors, and inductors integrated directly into the PCB substrate—are revolutionizing AV control board designs. This technology reduces the need for surface-mounted components, shrinking the overall footprint of the PCB by up to 30% and improving signal integrity by minimizing parasitic effects.

For instance, embedded capacitors can provide stable power delivery with capacitance values ranging from 1 nF to 10 μF, directly beneath high-speed ICs, reducing noise and enhancing performance. This is particularly beneficial for AV systems that require precise timing and low-latency responses. Additionally, embedded passives help lower assembly costs by reducing the number of soldering points, which also improves reliability by cutting down on potential failure spots.

The adoption of embedded passive components is a key trend for future AV PCBs, as it aligns with the need for miniaturization without compromising on functionality or performance.

Challenges and Opportunities in Autonomous Vehicle PCB Development

While the trends discussed above paint an exciting picture for the future of autonomous vehicle control PCBs, several challenges remain. Designing boards that can handle the massive data throughput required for AVs—often exceeding 100 terabytes per day—while maintaining reliability in harsh environments is no small feat. Additionally, balancing cost with performance is a constant concern, especially as sustainable materials and advanced technologies can drive up production expenses.

However, these challenges also present opportunities for innovation. Advances in simulation software allow engineers to test PCB designs virtually before production, reducing errors and costs. Collaboration between automotive and electronics industries is fostering the development of new materials and manufacturing techniques tailored specifically for AVs. For manufacturers willing to invest in research and development, the potential to lead in this rapidly growing market is immense.

How These Trends Impact Engineers and Manufacturers

For engineers working on AV systems, staying ahead of these trends means continuously updating skills in areas like high-frequency design, thermal management, and compliance with automotive standards. Familiarity with AI-optimized PCB hardware and 5G V2X technologies will be particularly valuable as these become standard in self-driving systems. Additionally, understanding the benefits and limitations of sustainable PCB materials can help in making informed choices during the design phase.

For manufacturers, the focus should be on scalability and adaptability. Investing in equipment capable of producing multi-layer PCBs with embedded components and high-frequency materials will be crucial. Building partnerships with material suppliers to source sustainable options can also provide a competitive edge in a market increasingly driven by environmental considerations.

Conclusion: Shaping the Future of Autonomous Driving with PCBs

The future of autonomous vehicle control PCBs is bright, driven by groundbreaking trends like AI-optimized PCB hardware, 5G V2X PCB technologies, sustainable PCB materials, autonomous vehicle-specific standards, and embedded passive components. These advancements are not just enhancing the performance and safety of self-driving cars but also paving the way for a more connected and eco-friendly automotive industry.

As technology continues to evolve, staying informed about these trends will be essential for engineers and manufacturers aiming to contribute to the next generation of autonomous vehicles. By embracing innovation and prioritizing reliability, the PCB industry can play a pivotal role in transforming transportation for years to come.

ALLPCB

ALLPCB