In the fast-evolving world of agriculture electronics, innovation is key to meeting the demands of modern farming. One technology that stands out as a game-changer is the rigid-flex PCB. But are rigid-flex PCBs truly the future of agriculture electronics? The answer lies in their unique ability to combine durability, flexibility, and space efficiency, making them ideal for the harsh and dynamic conditions of agricultural applications. In this blog, we’ll dive deep into how rigid-flex PCBs are transforming agriculture electronics, focusing on their benefits like vibration resistance, custom shapes, and size reduction.

What Are Rigid-Flex PCBs and Why Do They Matter in Agriculture?

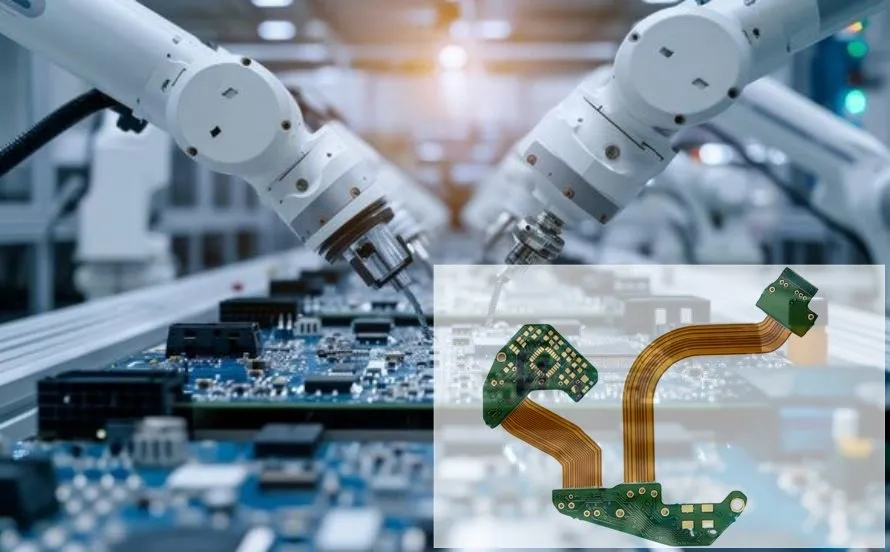

Rigid-flex PCBs are a hybrid of traditional rigid circuit boards and flexible circuits. They consist of both rigid and flexible sections, allowing them to bend and fold while maintaining structural integrity. This design offers a perfect balance of stability and adaptability, which is crucial for agriculture electronics where devices often face rough environments like dust, moisture, and constant movement.

In agriculture, electronics are used in everything from GPS-guided tractors to soil moisture sensors and drone systems. These devices need to be compact, durable, and reliable. Rigid-flex PCBs meet these needs by reducing the need for multiple connectors and cables, which can fail under stress. Their ability to fit into tight spaces and withstand vibrations makes them a top choice for modern farming tools.

Key Benefits of Rigid-Flex PCBs in Agriculture Electronics

Let’s explore the specific advantages of rigid-flex PCBs and why they are becoming a go-to solution for agricultural applications. These benefits directly address challenges like size constraints, environmental stress, and the need for tailored designs.

1. Space Efficiency with Reducing Size PCB Agriculture

Modern agricultural devices, such as wearable sensors for livestock or compact drones for crop monitoring, demand smaller, lighter electronics. Rigid-flex PCBs excel in reducing size by allowing designers to fold the board into tight spaces. Unlike traditional rigid boards, which require additional connectors for multi-dimensional layouts, rigid-flex designs integrate everything into a single unit. This can reduce the overall footprint by up to 60%, freeing up space for other components or making the device more portable.

For example, a compact soil sensor used in precision farming can be designed with a rigid-flex PCB to fit within a handheld device. The reduced size not only improves usability but also lowers material costs, making it a win-win for manufacturers and farmers alike.

2. Durability and Vibration Resistant Flexible PCB

Agricultural equipment often operates in tough conditions, enduring constant vibrations from machinery like tractors or harvesters. Traditional rigid PCBs can crack or lose connections under such stress, leading to costly downtime. Rigid-flex PCBs, with their vibration resistant flexible PCB design, are built to handle these challenges. The flexible portions absorb shocks and vibrations, while the rigid sections provide a stable base for mounting critical components.

Studies show that rigid-flex PCBs can withstand vibration frequencies up to 500 Hz without signal loss, compared to traditional boards that may fail at half that frequency. This durability ensures that devices like automated irrigation controllers or robotic harvesters keep running smoothly, even on uneven terrain.

3. Customization with Custom PCB Shape Agriculture

Every piece of agricultural equipment has unique design requirements. Whether it’s a curved sensor for a drone wing or a compact module for a smart sprinkler system, rigid-flex PCBs offer unparalleled flexibility in shape. The ability to create custom PCB shapes for agriculture means that designers can tailor electronics to fit specific equipment without sacrificing functionality.

For instance, a drone used for crop spraying might need a PCB that wraps around its aerodynamic frame. Rigid-flex technology allows for such bespoke designs, ensuring optimal performance and integration. This customization reduces assembly time and minimizes the risk of connection failures, as fewer external wires are needed.

4. Enhanced Reliability for Harsh Environments

Farming environments expose electronics to moisture, dust, and temperature swings. Rigid-flex PCBs are designed with fewer solder joints and connectors compared to traditional setups, reducing points of failure. Their materials, often including polyimide for the flexible layers, can handle temperatures from -40°C to 150°C, making them suitable for outdoor use in all seasons.

This reliability translates to longer-lasting devices, which is critical for farmers who rely on consistent performance from tools like weather monitoring stations or automated feeding systems. With rigid-flex PCBs, the risk of downtime due to electronic failure drops significantly.

Applications of Rigid-Flex PCB Agriculture in Modern Farming

The versatility of rigid-flex PCBs opens up a wide range of applications in agriculture electronics. Here are some key areas where this technology is making a difference, showcasing the potential of flexible PCB design in agriculture.

Precision Farming Tools

Precision farming relies on sensors and data to optimize crop yields. Devices like soil moisture sensors, nutrient analyzers, and weather trackers often use rigid-flex PCBs to pack complex circuitry into small, rugged packages. These boards allow for multi-layered designs that support high-speed data transmission, with signal integrity maintained at speeds up to 10 Gbps in some advanced setups.

The compact nature of rigid-flex designs also means farmers can deploy more sensors across a field without worrying about bulk or weight, leading to better data collection and smarter decision-making.

Autonomous Machinery and Robotics

From self-driving tractors to robotic weeders, autonomous machinery is revolutionizing agriculture. These machines need electronics that can endure constant motion and fit into non-standard shapes. Rigid-flex PCBs provide the necessary durability and design freedom, ensuring that control systems remain operational even after hours of bumpy fieldwork.

For example, a robotic arm used for fruit picking might integrate a rigid-flex PCB to manage motor controls and sensors within a confined, moving structure. The board’s ability to bend without breaking ensures seamless operation over long periods.

Drones for Crop Monitoring

Drones are increasingly used for aerial surveys, spraying, and monitoring crop health. Their electronics must be lightweight and resistant to vibrations from flight. Rigid-flex PCBs meet these needs by reducing weight (often by 30-50% compared to rigid-only boards) and providing a stable platform for high-frequency signals needed for real-time data processing.

A drone’s control module, for instance, might use a rigid-flex PCB to connect its camera, GPS, and communication systems in a single, folded design. This not only saves space but also improves the drone’s balance and flight efficiency.

Challenges to Consider with Rigid-Flex PCBs in Agriculture

While rigid-flex PCBs offer numerous advantages, there are challenges to keep in mind during design and implementation. Addressing these upfront can help ensure successful integration into agricultural systems.

Design Complexity

Designing a rigid-flex PCB requires careful planning, especially when it comes to bend radius and material selection. A bend radius that’s too tight can stress the flexible layers, leading to cracks or signal degradation. Typically, a minimum bend radius of 10 times the thickness of the flexible material is recommended to avoid damage.

Engineers must also balance the number of layers in the design. While more layers allow for greater functionality, they increase manufacturing costs and complexity. Collaboration between designers and manufacturers early in the process can help optimize the design for both performance and cost.

Cost Considerations

Rigid-flex PCBs can be more expensive to produce than traditional rigid boards due to the specialized materials and manufacturing processes involved. However, the long-term benefits—such as reduced maintenance and fewer failures—often outweigh the initial investment. For agriculture applications where reliability is critical, the cost is justified by the extended lifespan of the equipment.

How to Implement Rigid-Flex PCB Agriculture Solutions

For engineers and manufacturers looking to integrate rigid-flex PCBs into agricultural electronics, here are some practical steps to follow:

- Assess Device Requirements: Determine the environmental stresses (vibration, moisture, temperature) and space constraints your device will face. This helps in choosing the right materials and layout for the PCB.

- Focus on Flexibility: Identify areas where flexibility is needed, such as in moving parts or tight enclosures, and design the flexible sections accordingly.

- Test for Durability: Conduct thorough testing under real-world conditions to ensure the PCB can handle vibrations and temperature changes. Use simulation tools to predict performance before production.

- Partner with Experts: Work with experienced PCB fabricators who understand the nuances of rigid-flex technology to avoid common pitfalls and optimize the design.

The Future of Rigid-Flex PCBs in Agriculture Electronics

As agriculture continues to embrace technology, the role of rigid-flex PCBs will only grow. With advancements in materials and manufacturing, these boards are becoming more affordable and accessible, paving the way for wider adoption. Emerging trends like IoT integration in farming equipment and AI-driven analytics will further rely on the compact, reliable designs that rigid-flex PCBs enable.

Imagine a future where every piece of farm equipment, from seed planters to irrigation systems, is powered by lightweight, durable electronics tailored to its exact needs. Rigid-flex PCBs are at the heart of this vision, offering the flexibility and resilience required to push agricultural innovation forward.

Conclusion: A Step Toward Smarter Farming

Rigid-flex PCBs are more than just a trend—they are a transformative solution for agriculture electronics. Their ability to reduce size, resist vibrations, and adapt to custom shapes makes them ideal for the unique challenges of modern farming. Whether it’s enhancing precision tools, powering autonomous machinery, or supporting aerial drones, rigid-flex PCB agriculture applications are helping farmers achieve greater efficiency and sustainability.

By embracing flexible PCB design in agriculture, manufacturers can create devices that are not only more reliable but also better suited to the rugged demands of the field. As technology evolves, rigid-flex PCBs are poised to play a central role in shaping the future of smart farming, proving that sometimes, bending the rules of traditional design leads to the strongest results.

ALLPCB

ALLPCB