When designing printed circuit boards (PCBs) with buried resistors, selecting the right substrate material is critical for ensuring optimal performance, reliability, and efficiency. The substrate influences thermal conductivity, electrical properties, and the overall functionality of buried resistor PCBs. In this comprehensive guide, we’ll explore how to choose the best materials for your project, focusing on key factors like thermal conductivity, electrical properties, and buried resistor performance. Whether you're an engineer or a designer, this blog will help you make informed decisions for your next PCB design.

Why Substrate Materials Matter for Buried Resistor PCBs

Buried resistors are resistive elements embedded within the layers of a PCB, offering space-saving benefits and improved signal integrity compared to surface-mounted resistors. However, their performance heavily depends on the substrate material surrounding them. The right substrate ensures efficient heat dissipation, minimal signal loss, and stable electrical behavior under varying conditions. Choosing the wrong material can lead to overheating, signal distortion, or even failure of the entire circuit.

In the sections below, we’ll dive into the specifics of PCB substrate materials, focusing on how they impact buried resistor performance. We’ll cover thermal conductivity, electrical properties, and practical tips for selecting the best material for your needs.

What Are Buried Resistors and Why Do They Need Special Materials?

Buried resistors are integrated into the internal layers of a PCB during the manufacturing process. Unlike traditional resistors soldered onto the board’s surface, these components are part of the board’s structure, reducing the need for additional space and minimizing parasitic inductance and capacitance. This makes them ideal for high-frequency and high-density designs.

However, because buried resistors are embedded, they generate heat within the PCB layers, making thermal management a top priority. Additionally, the substrate material must support the resistor’s electrical properties, such as maintaining consistent resistance values and preventing signal interference. This dual demand for thermal and electrical performance makes substrate selection a critical step in PCB design.

Key Properties of PCB Substrate Materials for Buried Resistors

When choosing a substrate for buried resistor PCBs, several material properties come into play. Let’s break down the most important factors to consider, including thermal conductivity, electrical properties, and their impact on performance.

1. Thermal Conductivity of PCB Substrates

Thermal conductivity measures a material’s ability to transfer heat. For buried resistor PCBs, high thermal conductivity is essential to dissipate heat generated by the resistors and prevent hotspots that could damage the board or affect performance. Poor thermal management can lead to thermal expansion, delamination, or even component failure.

Common PCB substrate materials vary widely in their thermal conductivity:

- FR-4: A widely used epoxy-based laminate with a thermal conductivity of around 0.3–0.4 W/m·K. While cost-effective, it may not be suitable for high-power applications with buried resistors due to its limited heat dissipation capabilities.

- Aluminum-Based Substrates: These offer much higher thermal conductivity, typically around 1–2 W/m·K, making them a better choice for heat-intensive designs. However, they can be more expensive and less flexible in multilayer configurations.

- Ceramic Substrates: With thermal conductivity values ranging from 20–30 W/m·K, ceramics excel in heat dissipation. They are ideal for high-performance applications but come at a premium cost and may pose manufacturing challenges.

For buried resistor designs, balancing thermal conductivity with cost and manufacturability is key. If your application involves high power dissipation, opting for a substrate with higher thermal conductivity, like ceramic or aluminum, can significantly improve reliability.

2. Electrical Properties of PCB Substrates

The electrical properties of a substrate material directly affect signal integrity and buried resistor performance. Key parameters include dielectric constant (Dk), dissipation factor (Df), and insulation resistance.

- Dielectric Constant (Dk): This measures how much a material can store electrical energy in an electric field. A lower Dk value (e.g., 2.2–3.5 for high-frequency materials) is preferred for high-speed designs as it reduces signal delay and crosstalk. FR-4 typically has a Dk of 4.2–4.8, which may not be ideal for high-frequency buried resistor applications.

- Dissipation Factor (Df): This indicates the energy loss in the material. A lower Df (e.g., 0.002–0.005 for specialized laminates) minimizes signal loss, which is critical for maintaining the accuracy of buried resistors in high-frequency circuits. Standard FR-4 has a Df of about 0.02, which can lead to noticeable losses.

- Insulation Resistance: High insulation resistance ensures that the substrate prevents unwanted current leakage between layers, protecting the buried resistors’ performance.

For designs where signal integrity is paramount, selecting a substrate with optimized electrical properties is non-negotiable. Materials designed for high-frequency applications often provide the low Dk and Df values needed to support buried resistor performance.

3. Mechanical Stability and Compatibility

Beyond thermal and electrical properties, the substrate must offer mechanical stability to withstand the stresses of manufacturing and operation. Buried resistors are integrated during the lamination process, so the substrate material must be compatible with the resistive paste or film used. Additionally, the material should resist warping or cracking under thermal cycling, ensuring long-term reliability.

Materials like FR-4 are mechanically robust and widely compatible with standard manufacturing processes, while ceramics may require specialized handling due to their brittleness. Consider the entire production workflow when selecting a substrate to avoid costly delays or defects.

Popular Substrate Materials for Buried Resistor PCBs

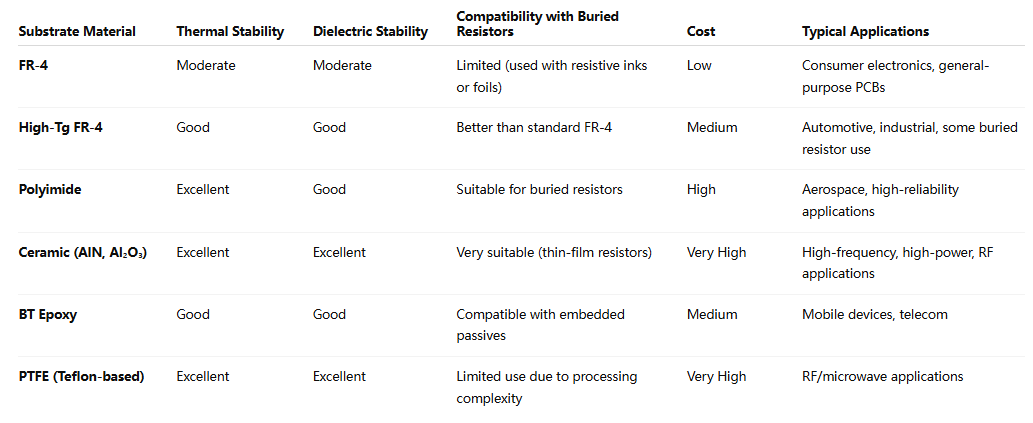

Now that we’ve covered the key properties to look for, let’s explore some of the most common substrate materials used in buried resistor PCBs and their pros and cons.

FR-4: The Standard Choice

FR-4 is the most widely used PCB substrate material due to its affordability and versatility. It’s a composite of woven fiberglass and epoxy resin, offering decent mechanical strength and electrical insulation. However, its low thermal conductivity (0.3–0.4 W/m·K) and moderate electrical properties (Dk of 4.2–4.8) make it less ideal for high-performance buried resistor designs. It works best for low- to medium-power applications where cost is a primary concern.

High-Frequency Laminates: Optimized for Signal Integrity

High-frequency laminates are engineered for applications requiring excellent electrical properties. These materials often have a dielectric constant below 3.5 and a dissipation factor as low as 0.002, making them perfect for high-speed designs with buried resistors. While they offer better performance than FR-4, they are more expensive and may require specialized manufacturing techniques.

Metal-Core Substrates: Superior Heat Dissipation

Metal-core substrates, often aluminum-based, provide excellent thermal conductivity (1–2 W/m·K or higher), making them a strong choice for power-intensive buried resistor PCBs. They are commonly used in LED lighting and automotive applications where heat management is critical. However, their higher cost and potential challenges in multilayer designs may limit their use in some projects.

Ceramic Substrates: High Performance at a Premium

Ceramic substrates, such as alumina or aluminum nitride, offer unmatched thermal conductivity (20–30 W/m·K) and excellent electrical insulation. They are ideal for extreme environments, including aerospace and military applications. However, their high cost and brittleness make them less common in mainstream PCB designs.

How Substrate Choice Impacts Buried Resistor Performance

The performance of buried resistors is directly tied to the substrate material’s ability to manage heat and maintain electrical stability. Let’s look at specific ways the substrate influences performance:

- Resistance Stability: Buried resistors rely on consistent material properties to maintain their resistance values. Substrates with high thermal expansion or poor insulation can cause resistance drift, affecting circuit accuracy.

- Heat Dissipation: As buried resistors are enclosed within the PCB, heat buildup can degrade performance or cause failure. Substrates with high thermal conductivity help spread heat evenly, protecting the resistors and surrounding components.

- Signal Integrity: In high-frequency designs, the substrate’s dielectric properties play a major role in minimizing signal loss and crosstalk. A mismatched substrate can compromise the performance of buried resistors in critical signal paths.

By carefully matching the substrate to the specific demands of your design—whether it’s high power, high frequency, or cost-sensitive—you can optimize buried resistor performance and extend the lifespan of your PCB.

Tips for Choosing the Right Substrate for Buried Resistor PCBs

Selecting the best substrate material involves balancing performance requirements with budget and manufacturing constraints. Here are some practical tips to guide your decision:

- Assess Power and Heat Requirements: If your design involves high power dissipation, prioritize substrates with high thermal conductivity, such as metal-core or ceramic materials.

- Consider Frequency Needs: For high-frequency applications, choose a substrate with a low dielectric constant and dissipation factor to ensure signal integrity.

- Evaluate Cost vs. Performance: While advanced materials offer superior properties, they often come at a higher cost. Determine if the performance gains justify the expense for your project.

- Consult with Manufacturers: Work closely with your PCB fabrication partner to ensure the chosen substrate is compatible with their processes and the resistive materials used for buried resistors.

- Test Under Real Conditions: Simulate or prototype your design to verify how the substrate performs with buried resistors under operating conditions, including thermal cycling and electrical stress.

Conclusion: Making an Informed Choice for Buried Resistor PCBs

Choosing the right substrate material for buried resistor PCBs is a decision that can make or break your design. By understanding the thermal conductivity, electrical properties, and mechanical characteristics of different materials, you can select a substrate that enhances buried resistor performance and meets the unique needs of your project. Whether you opt for the affordability of FR-4, the heat dissipation of metal-core substrates, or the high performance of ceramics, each material has its place in the world of PCB design.

At ALLPCB, we’re committed to helping you navigate these choices with expert guidance and top-quality manufacturing solutions. By focusing on the right buried resistor materials and PCB substrate materials, you can achieve designs that are efficient, reliable, and ready for the challenges of modern electronics.

ALLPCB

ALLPCB