In the world of printed circuit board (PCB) manufacturing, staying compliant with environmental regulations is more important than ever. If you're searching for clarity on the lead-free HASL process and RoHS compliance, you're in the right place. This guide will break down what lead-free HASL is, how it aligns with RoHS standards, and why it matters for your projects. We'll also explore lead-free solder alloys, environmental regulations, and even HASL alternatives to help you make informed decisions.

Whether you're an engineer, designer, or manufacturer, this comprehensive blog will walk you through every detail of the lead-free HASL process and its role in creating eco-friendly, high-quality PCBs. Let's dive in and explore how this surface finish can meet both technical and regulatory needs.

What is Lead-Free HASL and Why Does It Matter?

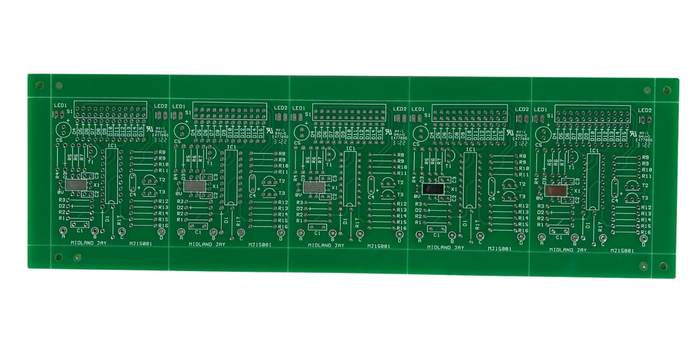

Hot Air Solder Leveling (HASL) is a widely used surface finish in PCB manufacturing. It involves dipping the board into molten solder and then using hot air to level the coating, creating a smooth, solderable surface on the copper pads. Traditionally, HASL used a tin-lead alloy, but with growing environmental concerns and stricter regulations, the industry has shifted to lead-free HASL.

Lead-free HASL replaces the traditional tin-lead solder with alloys that do not contain lead, making it compliant with environmental standards like RoHS (Restriction of Hazardous Substances). This shift is crucial because lead is toxic and poses significant risks to both human health and the environment if not handled or disposed of properly. By adopting lead-free HASL, manufacturers ensure safer products and contribute to a cleaner planet.

The importance of lead-free HASL extends beyond compliance. It offers reliable solderability for surface-mount and through-hole components, making it a cost-effective choice for many applications. Plus, it withstands multiple soldering cycles, which is vital for complex PCB designs.

Understanding RoHS Compliance and Its Impact on PCB Manufacturing

RoHS is a directive introduced by the European Union to limit the use of hazardous substances in electrical and electronic equipment. First implemented in 2006, RoHS restricts six harmful materials, including lead, mercury, and cadmium, with lead being a primary focus in PCB manufacturing due to its historical use in solder.

For a PCB to be RoHS compliant, it must contain less than 0.1% lead by weight in homogeneous materials. This regulation pushed the industry to develop lead-free alternatives, including lead-free HASL and lead-free solder alloys. Non-compliance can result in restricted market access, fines, or damage to a company's reputation, especially for businesses exporting to regions with strict environmental laws.

RoHS compliance isn't just about avoiding penalties. It's also about meeting customer expectations. Many industries, from automotive to consumer electronics, now demand RoHS-compliant components as part of their commitment to sustainability. Choosing a lead-free HASL process ensures your PCBs meet these global standards.

The Lead-Free HASL Process: How It Works

The lead-free HASL process is similar to traditional HASL but uses lead-free solder alloys, typically tin-silver-copper (Sn-Ag-Cu) or tin-copper (Sn-Cu). Here's a step-by-step look at how it's done:

- Cleaning: The PCB is cleaned to remove any contaminants from the copper surfaces, ensuring proper adhesion of the solder.

- Flux Application: A flux layer is applied to prevent oxidation and improve solder wetting during the process.

- Solder Dipping: The board is immersed in a bath of molten lead-free solder, coating the exposed copper areas.

- Hot Air Leveling: Hot air knives blow across the board to remove excess solder, leaving a thin, even layer on the pads.

- Cooling and Inspection: The board cools down, and the finish is inspected for uniformity and defects like uneven coating or solder bridges.

One key difference in the lead-free HASL process is the higher melting temperature of lead-free alloys compared to traditional tin-lead solder. For example, while tin-lead solder melts at around 183°C, lead-free alloys like Sn-Ag-Cu often require temperatures above 217°C. This means manufacturers must adjust their equipment and processes to handle the increased thermal stress on the PCB substrate.

Lead-Free Solder Alloys: Composition and Benefits

Lead-free solder alloys are the backbone of the lead-free HASL process. The most common alloys used include:

- Sn-Ag-Cu (SAC): This alloy, often with a composition like Sn-3.0Ag-0.5Cu, is popular for its excellent mechanical strength and thermal reliability. It's widely used in high-performance applications.

- Sn-Cu: A simpler alloy with no silver, Sn-Cu is more cost-effective but offers slightly lower performance in terms of durability compared to SAC alloys.

- Sn-Bi (Tin-Bismuth): This alloy has a lower melting point, making it suitable for temperature-sensitive components, though it's less common in HASL due to brittleness concerns.

These alloys provide several benefits beyond RoHS compliance. They offer good wetting properties, ensuring strong solder joints, and are compatible with modern assembly techniques. However, their higher melting points can pose challenges, such as potential thermal damage to components or substrates if not managed properly. Manufacturers often mitigate this by selecting materials with higher thermal resistance or optimizing soldering profiles.

Environmental Regulations Driving the Shift to Lead-Free HASL

Beyond RoHS, several global environmental regulations encourage or mandate the use of lead-free processes in electronics manufacturing. Here are a few key frameworks:

- WEEE (Waste Electrical and Electronic Equipment Directive): Also from the EU, WEEE focuses on the recycling and disposal of electronic waste, complementing RoHS by ensuring hazardous materials like lead don't end up in landfills.

- China RoHS: Similar to the EU directive, China's version imposes restrictions on hazardous substances and requires labeling to indicate compliance.

- California Proposition 65: In the U.S., this regulation requires warnings for products containing harmful chemicals like lead, pushing manufacturers toward safer alternatives.

These regulations reflect a global trend toward sustainability in electronics. By adopting lead-free HASL, manufacturers not only comply with these laws but also position themselves as environmentally responsible, which can be a competitive advantage in today's market.

Advantages and Challenges of Lead-Free HASL

Advantages

- Cost-Effectiveness: Compared to other lead-free finishes like ENIG (Electroless Nickel Immersion Gold), lead-free HASL is more affordable, making it ideal for budget-conscious projects.

- Reliability: It provides excellent solderability and can withstand multiple reflow cycles, which is critical for double-sided or complex boards.

- RoHS Compliance: It meets stringent environmental standards, ensuring market access and customer trust.

Challenges

- Higher Processing Temperatures: As mentioned, lead-free alloys require higher temperatures, which can stress PCB materials or components if not carefully controlled.

- Uneven Coating: HASL, even in its lead-free form, can sometimes result in uneven solder thickness, which may affect the placement of fine-pitch components.

- Limited Shelf Life: The solder coating can oxidize over time if not stored properly, reducing solderability.

HASL Alternatives: Exploring Other Lead-Free Surface Finishes

While lead-free HASL is a popular choice, it's not the only option for achieving RoHS compliance. Here are some common HASL alternatives, each with its own strengths:

- ENIG (Electroless Nickel Immersion Gold): This finish offers a flat surface ideal for fine-pitch components and excellent corrosion resistance. However, it's more expensive than HASL, with costs often 2-3 times higher.

- OSP (Organic Solderability Preservative): A thin organic coating protects copper pads from oxidation. It's cost-effective and environmentally friendly but has a shorter shelf life and isn't as durable during multiple soldering cycles.

- Immersion Tin: This provides a flat, lead-free finish with good solderability. However, it's prone to whisker growth, which can cause short circuits over time.

- Immersion Silver: Known for excellent conductivity and a flat surface, this finish is suitable for high-frequency applications but can tarnish if exposed to air for extended periods.

Choosing between lead-free HASL and these alternatives depends on your project's specific needs, such as budget, component density, and environmental exposure. For instance, if you're working on a high-density board with fine-pitch components, a flatter finish like ENIG might be worth the extra cost.

How to Choose the Right Surface Finish for RoHS Compliance

Selecting a surface finish for your PCB involves balancing technical requirements, cost, and regulatory compliance. Here are some factors to consider when deciding if lead-free HASL is the right choice:

- Application: For general-purpose or cost-sensitive projects, lead-free HASL is often sufficient. For high-reliability or high-frequency designs, consider alternatives like ENIG or immersion silver.

- Thermal Requirements: Ensure your PCB materials and components can withstand the higher temperatures required for lead-free soldering (typically 240-260°C for reflow).

- Component Type: If your design includes fine-pitch or BGA (Ball Grid Array) components, a flatter finish might be necessary to avoid soldering issues.

- Environmental Standards: Verify that the finish meets the specific regulations in your target markets, whether it’s EU RoHS, China RoHS, or others.

By evaluating these factors, you can ensure your PCB not only performs well but also adheres to environmental guidelines.

Best Practices for Implementing Lead-Free HASL in Manufacturing

To get the most out of the lead-free HASL process, manufacturers should follow these best practices:

- Material Selection: Choose PCB substrates and components rated for higher temperatures to avoid damage during soldering.

- Process Control: Monitor solder bath temperature and hot air leveling parameters to achieve a uniform coating and prevent defects.

- Storage Conditions: Store finished boards in a controlled environment to minimize oxidation of the solder coating, ideally with desiccants or vacuum packaging.

- Testing: Perform solderability and thermal stress tests to ensure the finish meets quality standards, especially for critical applications.

Implementing these practices can help maximize the reliability and longevity of your PCBs while maintaining compliance with environmental regulations.

Conclusion: Embracing Lead-Free HASL for a Sustainable Future

The shift to lead-free HASL represents a significant step forward in PCB manufacturing, aligning the industry with global environmental regulations like RoHS. By understanding the lead-free HASL process, the benefits of lead-free solder alloys, and the available HASL alternatives, you can make informed decisions that balance performance, cost, and sustainability.

Lead-free HASL offers a reliable, cost-effective solution for many applications, ensuring strong solder joints and compliance with strict standards. While challenges like higher processing temperatures exist, they can be managed with proper planning and expertise. For projects where HASL may not be ideal, exploring other finishes can provide the tailored solution you need.

As environmental regulations continue to evolve, adopting lead-free processes is not just a requirement but also a commitment to a greener future. Whether you’re designing consumer electronics, automotive systems, or industrial equipment, lead-free HASL can play a vital role in meeting both technical and ethical goals.

ALLPCB

ALLPCB