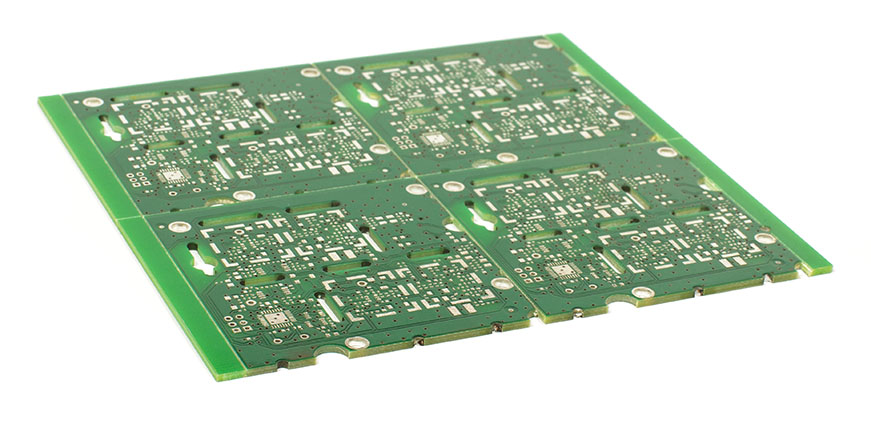

When designing printed circuit boards (PCBs), one critical aspect often overlooked is how individual boards will be separated from a larger panel after manufacturing. This process, known as depanelization, relies heavily on breakaway tab design. Two common methods stand out: perforation (often called mouse bites) and V-score (also known as V-groove). But which one should you choose for your project? In this guide, we’ll compare PCB breakaway tab perforation design and PCB V-score design rules, diving into their strengths, weaknesses, and best use cases to help you make an informed decision.

Whether you’re optimizing for strength, ease of separation, or manufacturing efficiency, this detailed exploration of mouse bite vs V-score comparison, breakaway tab strength comparison, and PCB depanelization methods will equip you with the knowledge to design panels that meet your project’s needs. Let’s break it down step by step.

What Are Breakaway Tabs and Why Do They Matter in PCB Design?

Breakaway tabs are small connectors that hold individual PCBs together within a larger panel during manufacturing and assembly. These tabs ensure stability while components are soldered or tested, but they’re designed to be easily removed once the process is complete. Without well-designed tabs, you risk damaging boards during separation or complicating the manufacturing workflow.

The choice of breakaway tab design directly impacts production costs, board integrity, and the final product’s quality. A poorly designed tab can lead to jagged edges, stress cracks, or even component damage. That’s why understanding the differences between perforation (mouse bites) and V-score methods is essential for any engineer working on PCB panelization.

Understanding PCB Breakaway Tab Perforation Design (Mouse Bites)

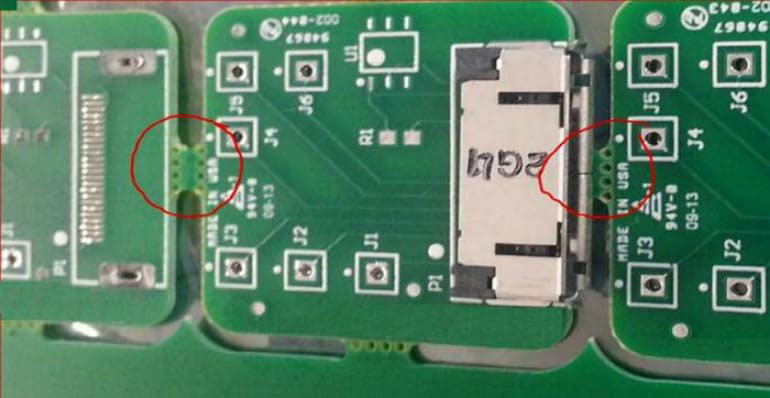

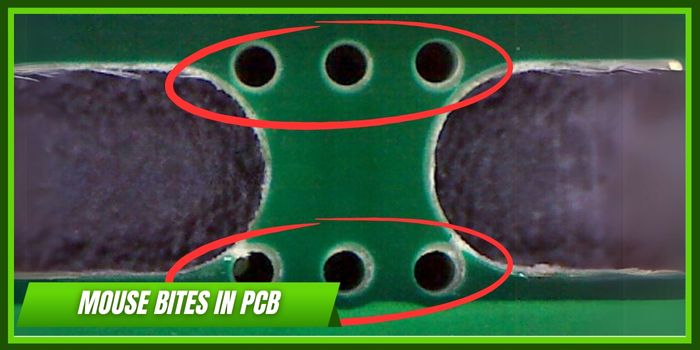

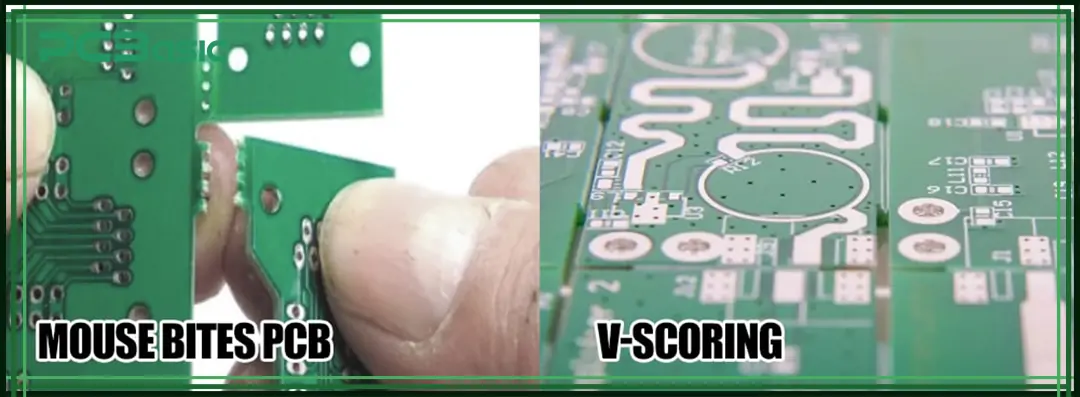

Perforation design, commonly referred to as "mouse bites," involves creating a series of small, drilled holes along the breakaway tab. These holes weaken the connection between the individual PCB and the panel, making it easier to snap the board free by hand or with minimal tools. The name "mouse bites" comes from the resemblance of these perforated holes to tiny bite marks.

How Mouse Bites Work

In a typical mouse bite design, a row of holes (often 0.3 mm to 0.5 mm in diameter) is drilled along the tab area, spaced closely together (usually 0.5 mm to 1 mm apart). The remaining material between holes acts as a weak link, allowing the board to break cleanly when force is applied. The number of holes and the spacing can be adjusted based on the desired strength of the tab.

Advantages of Mouse Bites

- Flexibility: Mouse bites work well for irregular board shapes or when V-scoring isn’t feasible due to design constraints.

- Cost-Effective: This method is often cheaper to implement, especially for small production runs, as it doesn’t require specialized cutting tools during manufacturing.

- Manual Separation: Boards can often be separated by hand without advanced equipment, making it ideal for prototypes or low-volume projects.

Drawbacks of Mouse Bites

- Rough Edges: Breaking the board can leave rough or jagged edges, which may require additional finishing if aesthetics or safety are concerns.

- Stress Risk: The force needed to snap the board can introduce mechanical stress, potentially damaging nearby components or traces.

- Limited Strength: Mouse bites are generally weaker than other methods, so they might not hold up during rigorous assembly processes.

Exploring PCB V-Score Design Rules (V-Groove)

V-scoring, or V-groove, is a depanelization method where a V-shaped cut is made along the separation line on both sides of the PCB panel using a specialized cutting tool. This creates a thin, weakened section of material that allows the board to be snapped apart with precision.

How V-Scoring Works

In V-scoring, a 30-degree or 45-degree angled blade cuts into the PCB from both the top and bottom, leaving a small amount of material (typically 0.3 mm to 0.5 mm thick) in the center. This remaining material, known as the web, holds the panel together during manufacturing but is weak enough to break cleanly when needed. The depth and angle of the cut are critical to ensuring both stability and ease of separation.

Key V-Score Design Rules

- Board Thickness: V-scoring is most effective on boards between 0.6 mm and 2.0 mm thick. Thinner or thicker boards may not score properly or could crack unpredictably.

- Alignment: The top and bottom V-cuts must be perfectly aligned to avoid uneven stress during separation. Misalignment can lead to incomplete breaks or damage.

- Component Clearance: Keep components and traces at least 1.0 mm away from the V-score line to prevent damage from stress or cutting errors.

- Panel Layout: V-scoring works best for straight-line separations. Curved or irregular shapes are not suitable for this method.

Advantages of V-Scoring

- Clean Edges: V-scoring produces smoother edges compared to mouse bites, reducing the need for post-separation finishing.

- Precision: The controlled cutting process ensures consistent results, making it ideal for high-volume production.

- Strength: V-scored tabs are generally stronger during manufacturing, providing better support during assembly compared to perforations.

Drawbacks of V-Scoring

- Limited Flexibility: V-scoring is only suitable for straight-line separations, limiting its use for complex panel designs.

- Equipment Needs: It requires specialized machinery, which can increase manufacturing costs, especially for low-volume runs.

- Stress Concerns: Although less risky than mouse bites, improper V-scoring depth can still cause stress cracks during separation.

Mouse Bite vs V-Score Comparison: Which Should You Choose?

Deciding between mouse bites and V-scoring depends on your project’s specific requirements. Let’s break down the key differences in a mouse bite vs V-score comparison across critical factors.

Ease of Separation

Mouse bites are often easier to separate by hand, requiring minimal force or tools. However, this can lead to inconsistent results. V-scoring, while sometimes needing a slight bending force or a depaneling tool, offers more predictable and uniform separation.

Edge Quality

V-scoring wins when it comes to edge quality. The precise cuts leave clean, smooth edges, whereas mouse bites often result in rough or uneven edges that may need sanding or finishing.

Design Flexibility

If your PCB panel has irregular shapes or curved edges, mouse bites are the better choice since V-scoring is limited to straight lines. For rectangular or square boards in a grid layout, V-scoring is more efficient.

Manufacturing Cost

Mouse bites are generally more cost-effective for small runs or prototypes due to their simplicity. V-scoring, while more expensive due to the need for specialized tools, becomes economical at scale in high-volume production.

Breakaway Tab Strength Comparison: Mouse Bites vs. V-Score

In a breakaway tab strength comparison, V-scoring typically provides greater structural integrity during the manufacturing process. The web of material left by a V-score (often 0.3 mm to 0.5 mm thick) offers more resistance to accidental breaking compared to the thin bridges between holes in a mouse bite design. For instance, a V-scored tab might withstand forces up to 10-15 N during handling, while a mouse bite tab may fail at 5-8 N, depending on hole spacing and material thickness.

However, this strength comes at a trade-off. A stronger V-score tab might require more force to separate, potentially introducing stress if not designed correctly. Mouse bites, while weaker, can be tailored by adjusting the number and size of holes to balance strength and ease of separation.

Other PCB Depanelization Methods to Consider

Beyond mouse bites and V-scoring, there are other PCB depanelization methods worth exploring, depending on your project’s needs.

Routing (Tab Routing)

Routing involves cutting out most of the material around the PCB, leaving small tabs to hold it in place. These tabs are later broken or cut during depanelization. This method offers clean edges and works for complex shapes but can be time-consuming and costly due to the precision required.

Laser Cutting

Laser depanelization uses a focused beam to cut through the PCB material with extreme accuracy. It’s ideal for delicate or high-density boards where mechanical stress must be avoided. However, it’s significantly more expensive and slower than traditional methods.

Manual Cutting Tools

For very small runs or prototypes, manual tools like shears or rotary cutters can be used. This method is not recommended for production due to inconsistent results and high labor costs.

Best Practices for Designing Breakaway Tabs

Regardless of whether you choose perforation or V-score, following these best practices will ensure a successful design.

- Consider Board Material: FR-4, the most common PCB material, works well with both methods, but flexible or thinner materials may require specific adjustments to avoid cracking.

- Optimize Tab Placement: Place tabs away from sensitive components or high-stress areas. Typically, 2-3 tabs per side are sufficient for most designs.

- Test Prototypes: Before full production, test your breakaway tab design on a prototype panel to identify potential issues with strength or separation.

- Consult Manufacturer Guidelines: Different fabrication houses may have specific requirements or limitations for mouse bites or V-scoring. Always confirm compatibility before finalizing your design.

Conclusion: Making the Right Choice for Your PCB Design

Choosing between PCB breakaway tab perforation design and PCB V-score design rules comes down to balancing cost, design complexity, and production volume. Mouse bites offer flexibility and affordability, making them ideal for prototypes or irregular shapes. On the other hand, V-scoring provides cleaner edges and greater strength, perfect for high-volume, straight-line separations.

By understanding the nuances of mouse bite vs V-score comparison, conducting a breakaway tab strength comparison, and exploring various PCB depanelization methods, you can design panels that streamline manufacturing and protect the integrity of your boards. Take the time to evaluate your project’s needs, and you’ll ensure a smoother transition from panel to product.

With the right breakaway tab design, you’ll not only improve efficiency but also deliver high-quality PCBs that stand up to the demands of your application. Keep these insights in mind as you tackle your next design challenge.

ALLPCB

ALLPCB