If you're designing a pet tracking device, one of the most critical aspects is creating a robust PCB enclosure that can withstand the elements and the active lifestyle of pets. A well-designed pet tracking PCB enclosure must prioritize waterproofing and durability to ensure the device remains functional in various environments. In this comprehensive guide, we’ll dive into the essentials of pet tracking PCB enclosure design, focusing on waterproof pet tracker casing, durable pet tracker enclosure materials, and achieving standards like IP67 for pet trackers. Whether you're an engineer or a product designer, this blog will provide actionable insights to help you create a reliable and long-lasting pet tracking solution.

Why Waterproofing and Durability Matter in Pet Tracking Devices

Pets are unpredictable. They run through muddy fields, splash in puddles, and sometimes even take an unexpected swim. A pet tracking device must endure these conditions without failing. Waterproofing ensures that moisture doesn't damage the internal electronics, while durability protects the device from physical impacts, scratches, and wear over time. A poorly designed enclosure can lead to device failure, frustrated pet owners, and costly replacements. By focusing on a waterproof pet tracker casing and a durable pet tracker enclosure, you can build trust with users and ensure the tracker performs reliably for years.

In the following sections, we'll explore the key considerations for designing such enclosures, including material selection, waterproofing standards, and testing methods to guarantee durability.

Key Elements of Pet Tracking PCB Enclosure Design

Designing a pet tracking PCB enclosure involves balancing functionality, cost, and protection. Let’s break down the core elements you need to focus on during the design process.

1. Understanding the Role of the Enclosure

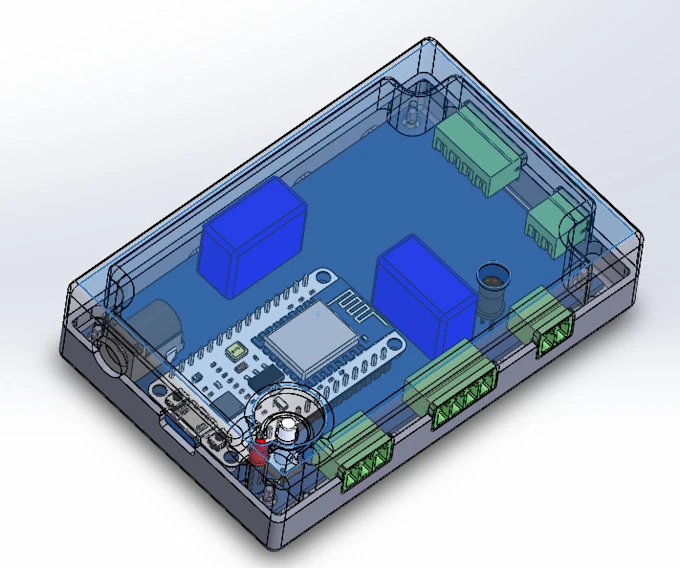

The primary purpose of a pet tracker enclosure is to safeguard the printed circuit board (PCB) and other sensitive components like GPS modules, batteries, and antennas. It acts as a barrier against environmental hazards such as water, dust, and physical shocks. A good design ensures that the device remains lightweight and comfortable for the pet while providing maximum protection.

2. Size and Weight Considerations

Pet trackers need to be compact and lightweight to avoid discomfort for the animal. The enclosure should be as small as possible while still accommodating the PCB and battery. For small pets like cats, aim for a total weight under 30 grams. For larger dogs, devices weighing up to 50-60 grams are generally acceptable. The enclosure design should minimize bulk by using thin yet strong materials and optimizing internal space for components.

3. Attachment Mechanism

The enclosure must integrate seamlessly with a collar or harness. Consider including secure mounting points or loops in the design to prevent the device from detaching during vigorous activity. Durability in these attachment points is just as important as in the main casing to avoid breakage.

Choosing the Right Pet Tracker Enclosure Materials

Material selection plays a pivotal role in achieving a durable pet tracker enclosure. The material must resist water, withstand impacts, and be safe for prolonged contact with a pet’s skin. Below are some commonly used materials for pet tracker enclosures and their benefits.

1. Polycarbonate

Polycarbonate is a popular choice for pet tracker enclosures due to its high impact resistance and lightweight nature. It can withstand drops and rough handling, making it ideal for active pets. Additionally, polycarbonate can be molded into complex shapes, allowing for ergonomic designs that fit comfortably on a pet’s collar.

2. ABS Plastic

Acrylonitrile Butadiene Styrene (ABS) is another durable and cost-effective option. It offers good resistance to scratches and minor impacts, though it may not be as tough as polycarbonate for extreme conditions. ABS is often used in budget-friendly pet trackers where cost is a significant factor.

3. Silicone Overmolding

For added protection, some enclosures use a hard plastic core with a silicone overmold. Silicone provides a soft, non-slip surface that’s comfortable for pets and enhances grip on collars. It also adds an extra layer of waterproofing and shock absorption.

4. Aluminum (for Premium Models)

In premium pet trackers, aluminum enclosures offer superior strength and a sleek look. While heavier than plastic, aluminum provides excellent durability and can be anodized for corrosion resistance. However, it’s typically reserved for high-end products due to its cost.

When selecting pet tracker enclosure materials, consider the target market and usage conditions. For example, a tracker for small indoor pets may prioritize lightweight plastic, while one for large outdoor dogs might benefit from a tougher material like polycarbonate or aluminum.

Achieving Waterproofing with IP67 for Pet Trackers

Waterproofing is non-negotiable for pet tracking devices, as exposure to rain, puddles, or even a quick swim can damage unprotected electronics. The IP67 rating is a widely recognized standard for waterproof and dustproof performance, making it a benchmark for pet trackers. Let’s explore what IP67 means and how to design a waterproof pet tracker casing that meets this standard.

Understanding the IP67 Rating

The IP67 rating stands for "Ingress Protection 67." The first digit, 6, indicates complete protection against dust. The second digit, 7, means the device can be submerged in water up to 1 meter deep for 30 minutes without damage. For pet trackers, this level of protection ensures reliability during outdoor adventures, even if a pet jumps into a lake or gets caught in heavy rain.

Design Tips for IP67 Compliance

Achieving an IP67 pet tracker requires careful attention to design details. Here are some practical tips:

- Sealed Joints: Use gaskets or O-rings made of silicone or rubber at all seams and openings to prevent water ingress. Ensure these seals are properly compressed when the enclosure is assembled.

- Screwless Design: Minimize the number of screws or use waterproof screws with sealing washers to reduce potential entry points for water.

- Port Protection: If the tracker has charging ports or buttons, cover them with waterproof silicone caps or integrate them into the sealed design.

- Material Bonding: Use adhesives or ultrasonic welding to bond enclosure parts, creating a seamless barrier against moisture.

Testing for Waterproofing

Once the design is complete, rigorous testing is essential. Simulate real-world conditions by submerging the device in water at a depth of 1 meter for 30 minutes, as per IP67 standards. Additionally, test for dust ingress using fine particles to ensure no gaps or weaknesses exist in the casing. Only after passing these tests can you confidently market your device as an IP67 pet tracker.

Ensuring Durability in Pet Tracker Enclosures

Beyond waterproofing, a durable pet tracker enclosure must resist physical damage from daily wear and tear. Pets can be rough on devices, so the enclosure needs to handle impacts, scratches, and constant movement. Let’s look at how to design for durability.

1. Impact Resistance

Drop tests are a standard way to evaluate impact resistance. Design the enclosure to withstand drops from heights of at least 1.5 meters onto hard surfaces. Reinforce corners and edges, as these areas are most prone to cracking. Using materials like polycarbonate or adding shock-absorbing features like silicone bumpers can significantly improve impact resistance.

2. Scratch and Abrasion Resistance

Pets often rub against rough surfaces or scratch at their collars. Choose materials with high scratch resistance or apply a protective coating to the enclosure. Textured finishes can also hide minor scratches, keeping the device looking new for longer.

3. Fatigue Resistance

Constant movement and vibration from a pet’s activity can cause material fatigue over time. Select materials with high fatigue resistance and avoid designs with thin, weak sections that might crack under repeated stress.

4. Temperature Tolerance

Pet trackers are exposed to a wide range of temperatures, from freezing winters to hot summer days. Ensure the enclosure material can operate within a temperature range of -20°C to 60°C without deforming or losing strength. Polycarbonate and ABS are good choices for maintaining performance across temperature extremes.

Manufacturing Considerations for Pet Tracker Enclosures

Once the design is finalized, manufacturing plays a critical role in ensuring the enclosure meets waterproofing and durability standards. Here are some key points to keep in mind during production.

1. Precision in Molding

For plastic enclosures, injection molding is the most common manufacturing method. Ensure molds are designed with tight tolerances to avoid gaps or misalignments that could compromise waterproofing. Work closely with manufacturers to maintain consistent quality across production batches.

2. Quality Control

Implement strict quality control checks during manufacturing. Inspect each enclosure for defects such as cracks, uneven seams, or weak spots. Conduct random waterproofing and durability tests on finished products to catch issues before they reach the market.

3. Cost vs. Performance

Balancing cost and performance is always a challenge. While high-end materials like aluminum offer superior durability, they increase production costs. For mass-market pet trackers, a combination of affordable plastics with strategic reinforcements can provide a good balance of cost and reliability.

Future Trends in Pet Tracking PCB Enclosure Design

As technology evolves, so do the expectations for pet tracking devices. Here are some emerging trends to consider when designing enclosures for the next generation of trackers.

1. Miniaturization

Advancements in PCB design and battery technology are allowing for smaller, more compact trackers. Enclosures must adapt to house these tiny components without sacrificing protection. Expect to see ultra-thin yet durable designs in the near future.

2. Sustainable Materials

With growing environmental awareness, there’s a push for eco-friendly materials in electronics. Biodegradable plastics or recycled materials could become viable options for pet tracker enclosures, provided they meet durability and waterproofing standards.

3. Smart Features

Future enclosures may integrate smart features like built-in sensors for temperature or pressure, requiring new design considerations for sealing and material compatibility. These innovations will demand even tighter integration between PCB and enclosure design.

Conclusion

Designing a pet tracking PCB enclosure that prioritizes waterproofing and durability is essential for creating a reliable product that pet owners can trust. By focusing on key aspects like material selection, IP67 waterproofing standards, and rigorous testing for durability, you can build a pet tracker that withstands the challenges of an active pet’s lifestyle. Whether you’re opting for lightweight plastics or premium aluminum, the goal remains the same: protect the electronics inside while ensuring comfort for the pet.

With the right approach to pet tracking PCB enclosure design, including a well-thought-out waterproof pet tracker casing and a durable pet tracker enclosure, your device will stand out in a competitive market. Keep innovating, testing, and refining your designs to meet the evolving needs of pet owners and their furry companions.

ALLPCB

ALLPCB