When it comes to creating reliable and strong solder joints in PCB assembly, selecting the right solder paste is the foundation of success. Solder paste acts as the critical bonding agent that connects components to the board, and its formula can make or break the quality of your solder joints. So, how do you choose the best solder paste for optimal results? The answer lies in understanding key factors like flux type, metal content, particle size, viscosity, and mastering processes such as solder paste printing, stencil design, reflow soldering, and proper storage. In this comprehensive guide, we’ll uncover the secrets of solder paste selection and provide actionable insights to help you achieve flawless solder joint formation every time.

Why Solder Paste Selection Matters for Solder Joint Quality

Solder paste is a mixture of tiny metal particles and flux, designed to hold components in place before melting during the reflow process to form a permanent bond. A poor choice of solder paste can lead to defects like insufficient wetting, voids, or weak joints, which compromise the reliability of your electronic devices. By focusing on the right composition and application techniques, you can ensure consistent, high-quality results. Let’s dive into the essential elements of solder paste and how they impact solder joint formation.

Key Factors in Solder Paste Selection

1. Flux Type: The Heart of Wetting and Cleaning

Flux is a vital component of solder paste, responsible for removing oxides from metal surfaces, improving wetting, and protecting the joint during heating. Choosing the right flux type depends on your assembly environment and the materials you’re working with. Here are the main types of flux commonly found in solder pastes:

- Rosin (RO): This flux has mild activity and works best in clean environments with easy-to-solder surfaces. It leaves a residue that may need cleaning but is less aggressive on sensitive components.

- Resin (RE): Offering higher activity than rosin, resin-based flux is suitable for moderately oxidized surfaces. It provides better wetting for challenging materials.

- Organic (OR): Highly active, organic flux is ideal for heavily oxidized or difficult-to-solder surfaces. It often requires thorough post-soldering cleaning to remove corrosive residues.

For most modern PCB assemblies, selecting a no-clean flux is a popular choice as it minimizes post-process cleaning while still providing effective oxide removal. Match the flux type to your board materials and cleaning capabilities for the best results.

2. Metal Content: Balancing Strength and Melting Point

The metal content in solder paste determines the strength, conductivity, and melting characteristics of the solder joint. Most solder pastes today are lead-free due to environmental regulations, with alloys like Sn-Ag-Cu (SAC) being the industry standard. A common formulation, SAC305 (96.5% tin, 3% silver, 0.5% copper), offers a melting point of around 217°C to 220°C, providing a good balance of strength and thermal performance.

The metal content typically ranges from 85% to 90% by weight in solder paste, with the remainder being flux. Higher metal content can improve joint strength but may affect printability due to increased viscosity. Consider your reflow oven’s temperature capabilities and the thermal limits of your components when selecting the alloy composition.

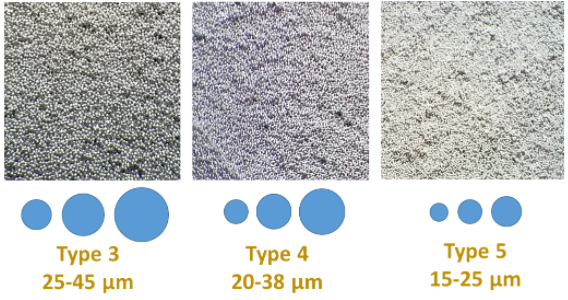

3. Particle Size: Precision for Fine-Pitch Applications

The size of the metal particles in solder paste plays a huge role in printing accuracy and joint formation, especially for fine-pitch components. Particle size is classified by industry standards, such as IPC J-STD 005, into types like Type 3 (25-45 μm), Type 4 (20-38 μm), and Type 5 (15-25 μm). Smaller particles are better suited for smaller stencil apertures and finer pitches, ensuring precise deposition.

For example, if you’re working on a PCB with 0.4mm pitch components, a Type 4 or Type 5 paste is ideal to avoid clogging the stencil and ensure even distribution. Larger particles (Type 3) are better for standard pitches above 0.5mm. Always align the particle size with your stencil design and component requirements to prevent defects like bridging or insufficient solder volume.

4. Viscosity: Ensuring Smooth Printing

Viscosity measures how easily solder paste flows during printing. A paste with the right viscosity will release cleanly from the stencil, creating uniform deposits on the PCB pads. Viscosity is influenced by the metal content, flux composition, and temperature. Typically, solder paste viscosity ranges from 600 to 1200 Kcps (kilo-centipoise), depending on the formulation.

For high-speed automated printing, a lower viscosity paste (around 600-800 Kcps) is often preferred for better flow. For manual or slower processes, a higher viscosity (900-1200 Kcps) helps maintain shape after printing. Test the paste under your specific printing conditions to ensure it meets the demands of your equipment and stencil design.

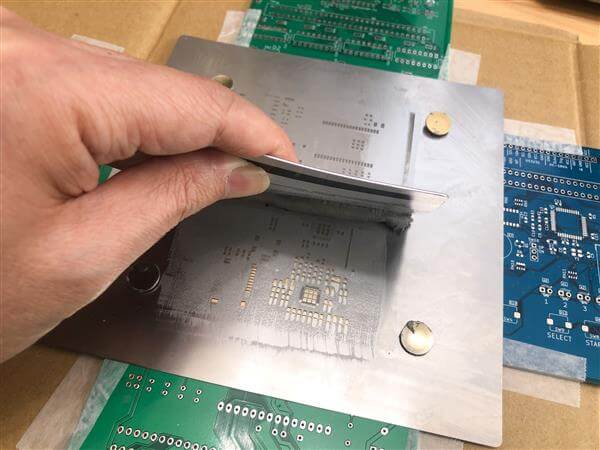

Mastering Solder Paste Printing and Stencil Design

1. Solder Paste Printing: The First Step to Perfection

Solder paste printing is one of the most critical steps in surface mount technology (SMT) assembly. It involves applying paste through a stencil onto the PCB pads using a squeegee. Poor printing can lead to defects like insufficient solder, bridging, or misalignment. To achieve optimal results, focus on these best practices:

- Printer Settings: Adjust squeegee pressure (typically 0.3-0.5 kg/cm of blade length) and speed (20-50 mm/s) to match the paste viscosity and stencil thickness.

- Environment Control: Maintain a temperature of 20-25°C and humidity of 40-60% in the printing area to prevent paste drying or oxidation.

- Regular Cleaning: Clean the stencil underside every 5-10 prints to avoid paste buildup and ensure consistent deposits.

2. Stencil Design: Precision in Every Aperture

The stencil acts as a template for solder paste application, and its design directly impacts print quality. Key considerations include:

- Thickness: Common stencil thicknesses range from 0.1mm to 0.15mm. Thinner stencils (0.1mm) are ideal for fine-pitch components to reduce paste volume, while thicker ones (0.15mm) suit larger components requiring more solder.

- Aperture Size: Apertures should match the pad size, with a typical area ratio of 0.66 or higher to ensure good paste release. For fine-pitch applications, consider a stepped stencil with varying thicknesses for different areas of the board.

- Material: Stainless steel stencils are durable and provide precise apertures, while laser-cut designs offer superior accuracy for intricate layouts.

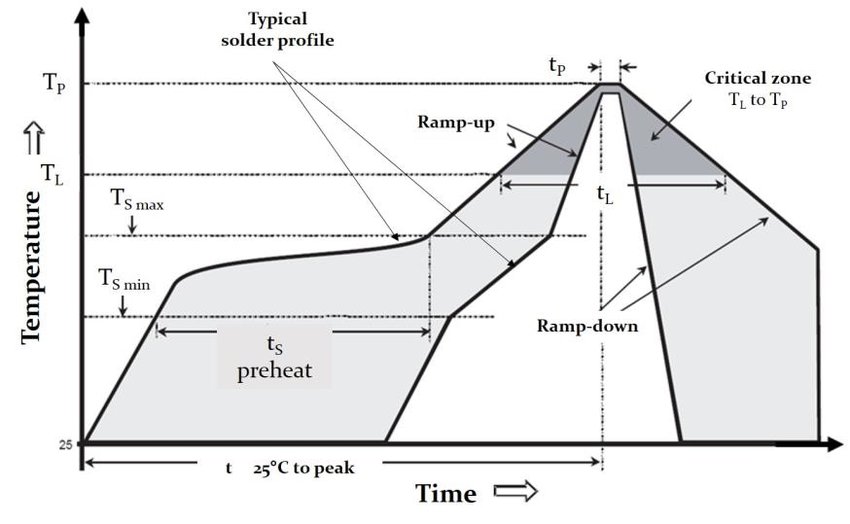

Reflow Soldering: Turning Paste into Perfect Joints

Reflow soldering transforms the applied solder paste into solid joints by heating the PCB in a controlled oven. A well-designed reflow profile is essential to avoid defects like tombstoning, voids, or component damage. A typical reflow profile for lead-free SAC305 paste includes four stages:

- Preheat (25°C to 150°C): Gradually heat the board over 60-90 seconds to activate the flux and evaporate solvents, preventing thermal shock. Ramp rate should be 1-3°C per second.

- Soak (150°C to 180°C): Hold for 60-120 seconds to ensure even temperature distribution and complete flux activation.

- Reflow (Peak at 235°C to 250°C): Reach the peak temperature for 20-40 seconds, allowing the solder to melt and form joints. Stay above the liquidus temperature (217°C for SAC305) for at least 30 seconds.

- Cooling (Below 217°C): Cool at a rate of 2-4°C per second to solidify the joints without creating thermal stress.

Monitor the reflow oven’s temperature zones and adjust the profile based on your board’s thermal mass and component specifications. Using a thermocouple to measure real-time temperatures on the PCB can help fine-tune the process.

Solder Paste Storage: Preserving Quality Over Time

Proper storage of solder paste is crucial to maintain its performance and shelf life. Incorrect handling can cause the paste to dry out, separate, or lose its effectiveness. Follow these guidelines to keep your solder paste in top condition:

- Temperature: Store solder paste in a refrigerator at 2-10°C to slow down chemical reactions in the flux. Avoid freezing, as it can damage the paste’s consistency.

- Sealing: Keep the paste in its original airtight container to prevent moisture absorption or contamination.

- Warm-Up: Before use, allow the paste to reach room temperature (20-25°C) for 4-6 hours. Avoid rapid heating, as it can cause condensation inside the container.

- Shelf Life: Most solder pastes have a shelf life of 6-12 months when refrigerated. Check the manufacturer’s expiration date and avoid using expired paste, as it may lead to poor wetting or inconsistent printing.

By maintaining strict storage conditions, you can maximize the lifespan of your solder paste and ensure consistent results in every assembly run.

Troubleshooting Common Solder Paste Issues

Even with the best solder paste and processes, issues can arise. Here are some common problems and solutions:

- Insufficient Solder: This can result from incorrect stencil thickness or low paste volume. Increase stencil thickness or adjust aperture size to deposit more paste.

- Bridging: Caused by excessive paste or misalignment, bridging can be fixed by reducing stencil apertures or improving printer alignment.

- Voids in Joints: Voids often occur due to incomplete flux activation or trapped gas. Optimize the reflow profile with a longer soak zone to allow outgassing.

Regular inspection using X-ray or visual methods after reflow can help identify defects early and guide process adjustments.

Conclusion: Unlocking the Power of Solder Paste for Perfect Joints

Choosing the right solder paste and mastering its application are the secrets to achieving optimal solder joint formation in PCB assembly. By carefully considering factors like flux type, metal content, particle size, and viscosity, you can select a paste tailored to your specific needs. Pair this with precise solder paste printing, thoughtful stencil design, a well-controlled reflow soldering process, and proper storage practices, and you’ll be on your way to creating reliable, high-quality solder joints every time.

At ALLPCB, we’re committed to supporting your PCB assembly journey with expert guidance and high-quality materials. Whether you’re working on fine-pitch components or high-volume production, understanding these solder paste secrets will elevate your manufacturing process to new heights. Keep experimenting, refining, and perfecting your techniques to stay ahead in the ever-evolving world of electronics assembly.

ALLPCB

ALLPCB