In the world of embedded systems, power consumption is a critical factor, especially for battery-powered devices. Whether you're designing IoT gadgets, wearable tech, or industrial sensors, knowing how to optimize power usage with microcontrollers can extend battery life and improve efficiency. This guide will dive deep into low power microcontroller design, microcontroller power saving techniques, and microcontroller power optimization methods to help you reduce energy consumption while maintaining performance.

At ALLPCB, we understand the importance of energy-efficient designs in modern electronics. In this comprehensive blog, we'll explore actionable strategies, practical examples, and specific techniques like STM32 low power modes to help you create sustainable and long-lasting embedded systems for battery powered microcontroller applications.

Why Power Optimization Matters in Embedded Systems

Embedded systems are everywhere—from smart home devices to medical equipment. Many of these systems rely on batteries, making power optimization a top priority. High power consumption can lead to shorter battery life, increased heat generation, and higher operational costs. By focusing on reducing microcontroller energy consumption, you can enhance device reliability, lower maintenance needs, and create products that stand out in competitive markets.

For instance, consider a wireless sensor node in a remote location. If it consumes too much power, frequent battery replacements become necessary, which is costly and impractical. Optimizing power usage ensures the device runs longer on a single charge, saving time and resources.

Understanding Microcontroller Power Consumption

Before diving into optimization techniques, let’s break down how microcontrollers consume power. Power usage in microcontrollers typically comes from three main areas:

- Active Mode: When the microcontroller is fully operational, executing instructions and running peripherals like timers or communication interfaces. This mode consumes the most power, often in the range of 100-500 μA/MHz for modern low-power chips.

- Idle Mode: When the CPU is not executing tasks but peripherals remain active. Power consumption drops significantly, sometimes to 50-100 μA.

- Sleep/Standby Mode: When most functions are turned off, and the system waits for an interrupt or event to wake up. Power usage can be as low as 0.1-1 μA in deep sleep modes.

Understanding these modes is the foundation of microcontroller power saving techniques. By leveraging the right mode at the right time, you can drastically cut down energy use.

Key Strategies for Low Power Microcontroller Design

Designing a low-power embedded system starts with selecting the right microcontroller and implementing smart design practices. Below are proven strategies to achieve efficient low power microcontroller design.

1. Choose the Right Microcontroller for Power Efficiency

Not all microcontrollers are created equal when it comes to power consumption. When selecting a microcontroller for battery powered microcontroller applications, look for one with built-in low-power features. For example, many 32-bit microcontrollers offer ultra-low-power modes with current draw as low as 0.3 μA in standby.

Consider the operating voltage as well. Some microcontrollers can run at lower voltages (e.g., 1.8V instead of 3.3V), which reduces power usage since power is proportional to the square of the voltage (P = V2/R). A drop from 3.3V to 1.8V can cut power consumption by nearly 70% in some cases.

2. Utilize Low Power Modes Effectively

Most modern microcontrollers come with multiple power modes. For instance, STM32 low power modes include options like Sleep, Stop, and Standby, each offering different levels of energy savings:

- Sleep Mode: Disables the CPU clock while keeping peripherals active. Current draw might be around 20-50 μA.

- Stop Mode: Shuts down most clocks and peripherals, retaining RAM content. Power consumption can drop to 1-5 μA.

- Standby Mode: Turns off nearly everything, with only a real-time clock or wake-up pin active. Consumption can be as low as 0.2 μA.

In an application like a temperature sensor, you can keep the microcontroller in Standby mode for most of the time, waking it up every few minutes to take a reading and transmit data. This approach can extend battery life from days to years.

3. Optimize Clock Speed and Peripherals

Running a microcontroller at full clock speed when it’s not necessary wastes power. Many systems don’t need to operate at 48 MHz or higher all the time. Lowering the clock speed to, say, 8 MHz can reduce power draw by a factor of 6, as power scales linearly with frequency.

Additionally, disable unused peripherals. For example, if your application doesn’t use an ADC (Analog-to-Digital Converter) or UART (Universal Asynchronous Receiver-Transmitter), turn them off in the firmware to save a few microamps per peripheral.

Microcontroller Power Saving Techniques for Firmware

Hardware design is only part of the equation. Firmware plays a huge role in reducing microcontroller energy consumption. Here are some effective techniques to implement in your code.

1. Implement Duty Cycling

Duty cycling involves putting the microcontroller into a low-power mode for most of the time and waking it up only when needed. For example, in a weather monitoring system, the device might wake up every 10 minutes to measure data, spending less than 1% of its time in active mode. This can reduce average current draw from hundreds of microamps to just a few.

2. Use Interrupts Instead of Polling

Polling—continuously checking for an event—keeps the CPU active and consumes power. Instead, use interrupts to wake the microcontroller only when an event occurs, such as a button press or sensor trigger. This keeps the system in a low-power state for longer periods.

3. Optimize Code for Efficiency

Write efficient code that executes tasks quickly, allowing the microcontroller to return to a low-power mode sooner. Avoid unnecessary loops or delays in the firmware. For instance, using a simple state machine can help manage tasks without wasting CPU cycles.

Advanced Microcontroller Power Optimization Methods

For engineers looking to push the limits of efficiency, advanced microcontroller power optimization methods can make a significant difference. These techniques require a deeper understanding of both hardware and software.

1. Dynamic Voltage and Frequency Scaling (DVFS)

Dynamic Voltage and Frequency Scaling adjusts the operating voltage and clock speed based on the workload. When high performance isn’t needed, the system lowers the voltage and frequency to save power. For example, reducing the clock from 48 MHz to 8 MHz and voltage from 3.3V to 2.5V can cut power usage by over 80% during low-demand tasks.

2. Power Gating for Unused Circuits

Power gating involves completely shutting down power to unused parts of the microcontroller or external components. This is more advanced than simply disabling peripherals through software and can save additional power, especially in complex systems with multiple modules.

3. Use Energy Harvesting for Battery-Powered Applications

In battery powered microcontroller applications, energy harvesting can supplement or even replace batteries. Techniques like solar panels or piezoelectric generators can provide small amounts of power to keep the system running without frequent battery changes. For instance, a solar-powered sensor might draw just 10 μA on average, allowing a small panel to sustain it indefinitely under sunlight.

Practical Examples of Power Optimization in Embedded Systems

Let’s look at a couple of real-world scenarios where power optimization makes a tangible impact.

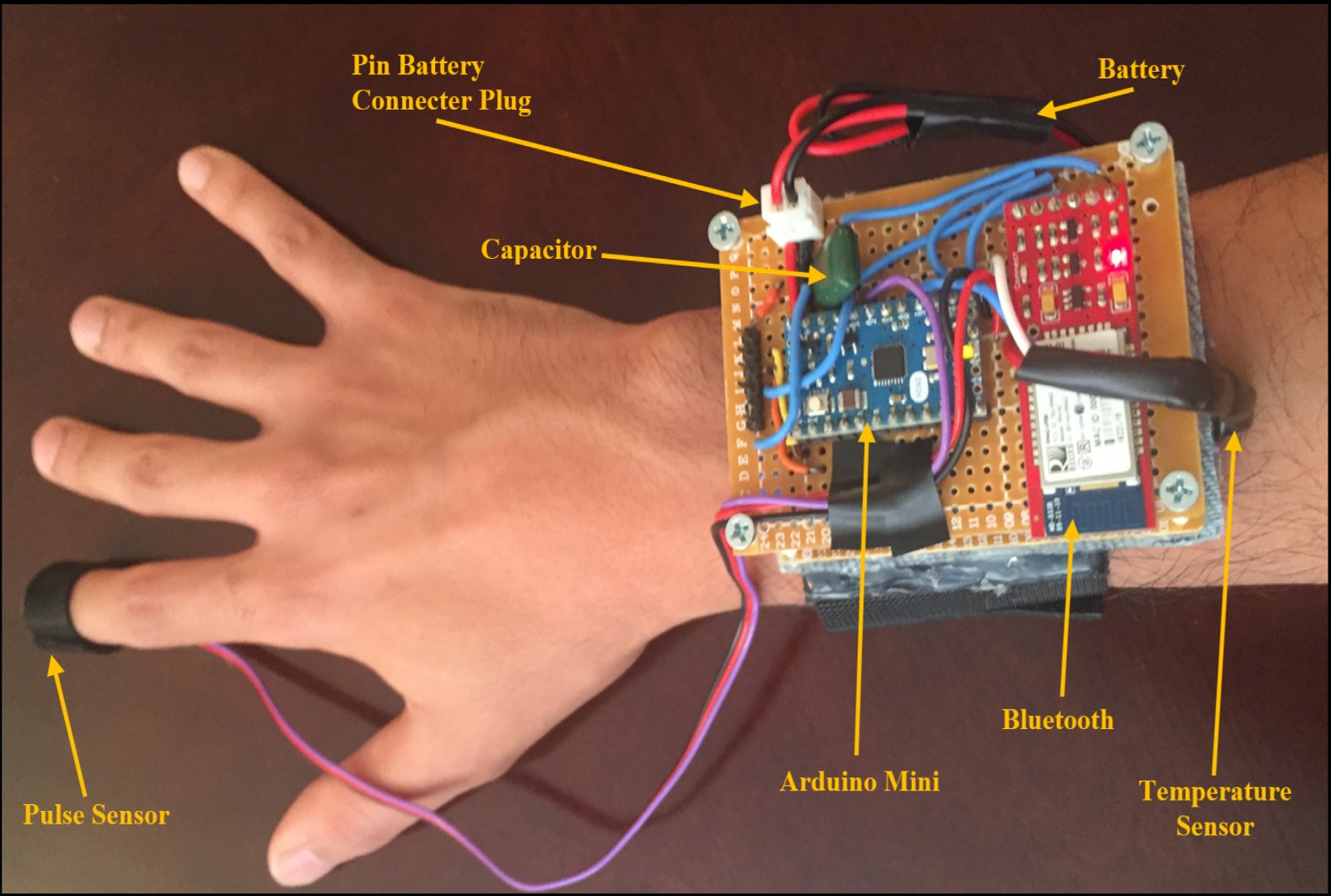

Example 1: Wearable Health Monitor

A wearable device tracking heart rate needs to operate 24/7 on a small coin cell battery. By using a microcontroller with ultra-low-power modes (e.g., 0.5 μA in standby), implementing duty cycling (active for 1 second every minute), and disabling unused peripherals, the device can achieve a battery life of over a year. Without optimization, the same device might last only a few weeks.

Example 2: Industrial Sensor Network

In an industrial setting, sensors monitor equipment and transmit data wirelessly. Using STM32 low power modes like Stop or Standby, combined with efficient firmware that minimizes active time, each sensor node can operate for 2-3 years on a single AA battery pair, reducing maintenance costs significantly.

Challenges in Power Optimization and How to Overcome Them

While optimizing power consumption offers many benefits, it comes with challenges. Balancing performance and power efficiency is often the biggest hurdle. For example, lowering clock speed saves power but may slow down critical tasks. To overcome this, use techniques like DVFS to dynamically adjust based on workload.

Another challenge is wake-up latency. Deep sleep modes save the most power but can take longer to wake up (sometimes 10-100 μs). If your application requires instant response, opt for lighter sleep modes or plan wake-up events carefully.

Tools and Resources for Power Optimization

To assist with microcontroller power optimization methods, consider using simulation tools and development kits. Many microcontroller manufacturers provide software to estimate power consumption based on your configuration. Additionally, hardware debuggers with current measurement capabilities can help you monitor real-time power usage during development.

At ALLPCB, we support engineers with high-quality PCB manufacturing and assembly services to bring your low-power designs to life. Our expertise ensures that your hardware is built to maximize efficiency and reliability.

Conclusion: Building Energy-Efficient Embedded Systems

Optimizing power consumption in embedded systems with microcontrollers is not just a trend—it’s a necessity for modern electronics. By focusing on low power microcontroller design, implementing microcontroller power saving techniques, and leveraging advanced methods like STM32 low power modes, you can significantly reduce microcontroller energy consumption. Whether you’re working on battery powered microcontroller applications or industrial systems, these strategies will help you create efficient, long-lasting products.

Start by selecting the right hardware, fine-tuning your firmware, and continuously testing power usage. With the right approach, you can achieve remarkable energy savings without sacrificing performance. Trust ALLPCB to be your partner in turning innovative, energy-efficient designs into reality.

ALLPCB

ALLPCB