Challenge

Budweiser Budvar Brewery operates a production site in ?eské Budějovice (Budweis), producing ten beer varieties whose labels are printed in dozens of languages and exported to 76 countries. This variety results in around 360 product combinations, requiring warehouse capacity for more than 20,000 pallets and support for two pallet-size specifications for indoor and outdoor storage.

Before exploring ultra-wideband (UWB) solutions, the brewery used a passive RFID system. The system placed RF ID anchors on forklifts and used roughly ten tags per tracked location. While it functioned initially, several limitations emerged over time:

- Reliability: Reliability issues caused operational interruptions.

- Maintenance cost: Maintaining and scaling the RFID infrastructure was expensive.

- Efficiency: System limitations produced operational waste and delays.

- Insufficient accuracy: The system could not consistently provide accurate, real-time location data needed for effective analytics.

Solution

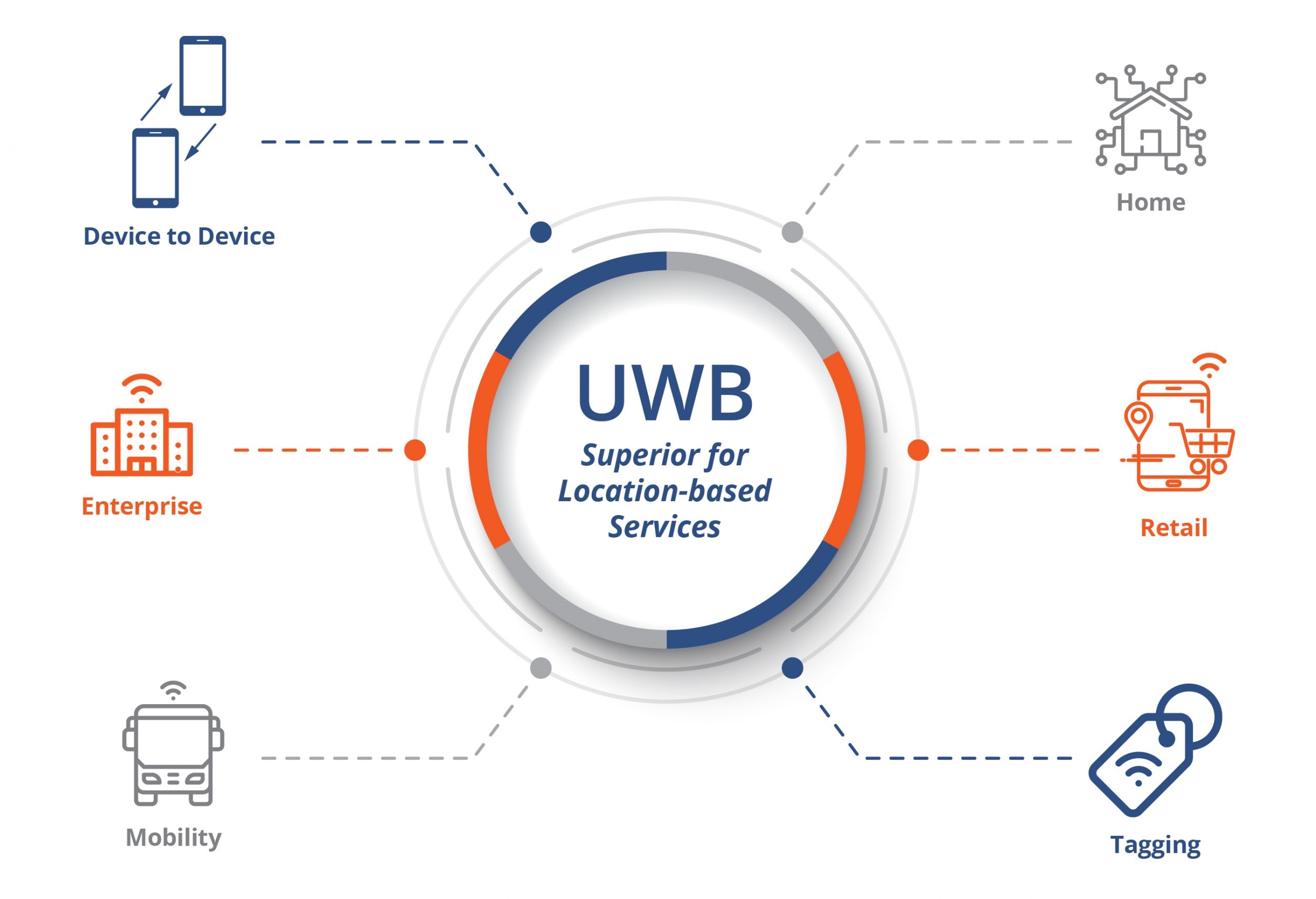

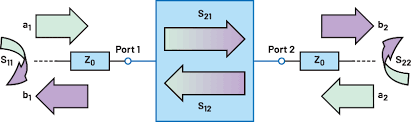

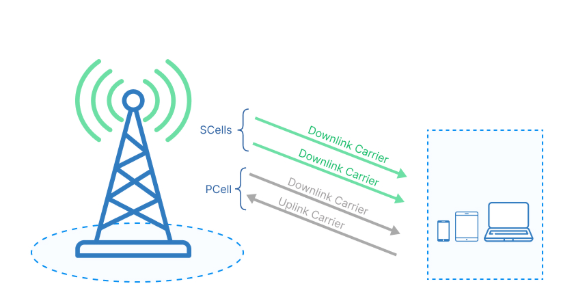

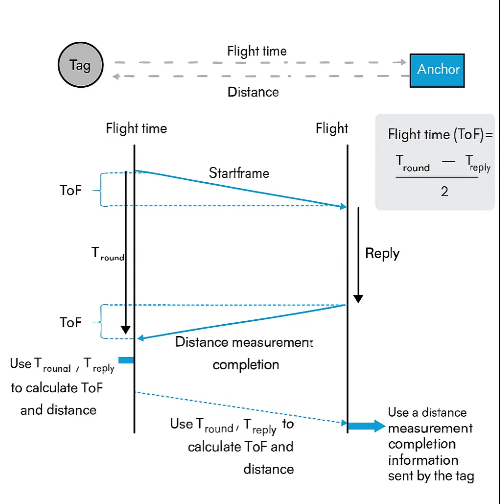

The brewery selected Sewio's UWB-based real-time locating system (RTLS). UWB uses time-of-flight (ToF) measurements to determine distances to tags. Employing multiple ToF techniques improved measurement accuracy while lowering infrastructure cost.

Techniques such as two-way ranging (TWR) and time difference of arrival (TDoA) mitigate the effects of reflections (multipath) caused by walls and machinery on signal strength. Other methods, including phase difference of arrival (PDoA) and reverse TDoA (RTDoA), offer advantages in different deployment scenarios. By combining these ranging techniques, UWB can determine both distance and direction (vector) of tracked objects.

Deployment

- Installation time: Sewio's UWB system installation took about one month. Engineers then spent approximately six months integrating the system with the existing enterprise resource planning (ERP) system.

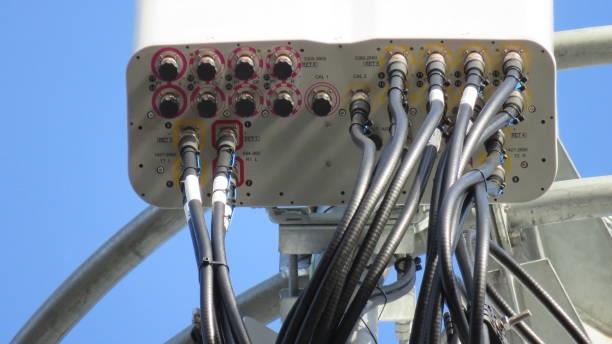

- Coverage: To cover indoor and outdoor warehouse areas totaling 15,000 square meters (17,940 square yards), the brewery deployed 70 UWB anchors and equipped 15 forklifts with tags, achieving about 30 cm positioning accuracy.

Results

After installation and integration of the UWB-based RTLS, the brewery reported:

- 19% increase in uptime: Compared with the previous RFID system, the UWB solution increased operational uptime by 19%, reducing warehouse interruptions.

- 19% improvement in warehouse utilization: The brewery achieved a 19% improvement in overall warehouse space utilization.

Conclusion

Adoption of UWB marked a notable change in the brewery's warehouse management. By addressing the limitations of the legacy RFID system and deploying a UWB-based RTLS, the operation improved efficiency and gained the real-time, high-precision location data required for advanced analytics. This case illustrates the potential of UWB-based micro-location services as the technology ecosystem and solution providers continue to develop.

ALLPCB

ALLPCB