Thermal profiling in SMT (Surface Mount Technology) assembly is a critical process for achieving high-quality solder joints and ensuring the reliability of electronic assemblies. If you're looking for SMT assembly thermal profiling best practices, reflow oven profiling techniques, or ways to optimize peak temperature in reflow and time above liquidus (TAL) optimization for solder joint reliability, you're in the right place. This guide will walk you through the essentials of thermal profiling, providing actionable steps and detailed insights to help you achieve peak performance in your reflow soldering process.

Whether you're a manufacturing engineer or a process technician, mastering thermal profiling can significantly reduce defects, improve product reliability, and streamline production. Let's dive into the comprehensive strategies and techniques that will elevate your SMT assembly process.

What is Thermal Profiling in SMT Assembly?

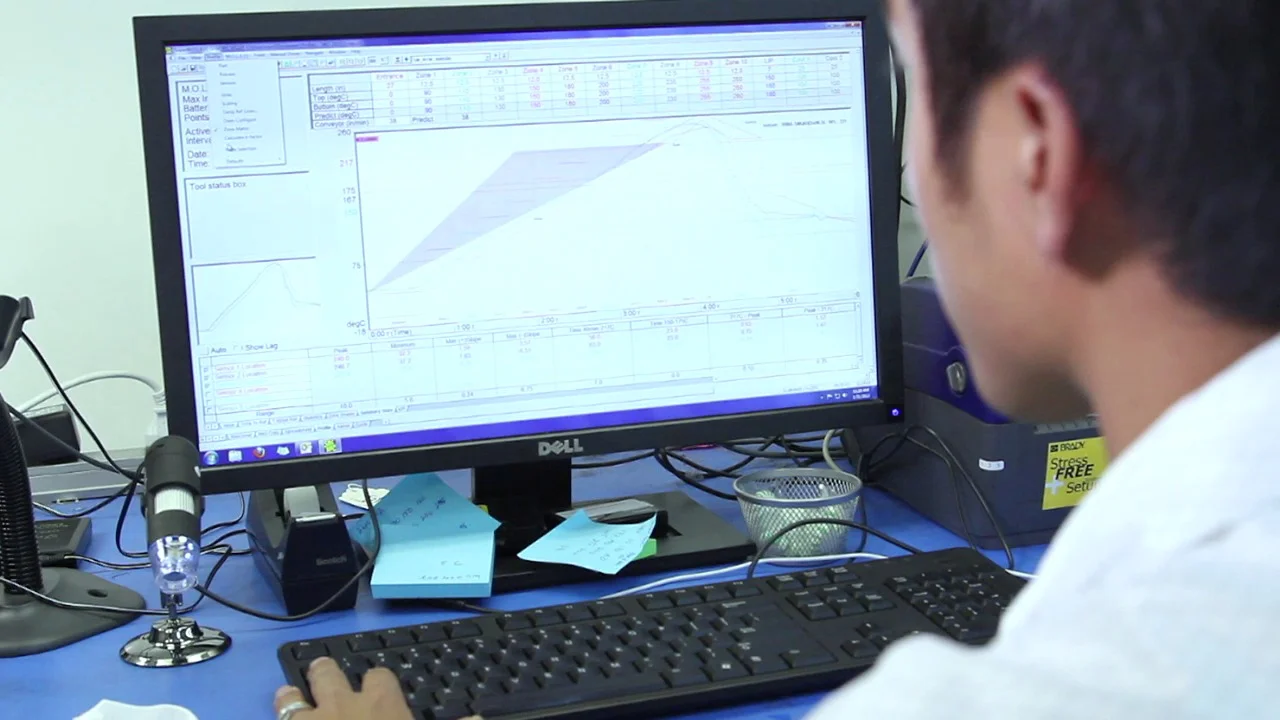

Thermal profiling refers to the process of monitoring and recording the temperature changes a printed circuit board (PCB) undergoes during the reflow soldering process in SMT assembly. By using specialized tools like thermocouples and profiling software, engineers can create a temperature profile that maps out how heat is applied across different stages of the reflow oven. This profile ensures that components and solder paste are heated and cooled in a controlled manner to form strong, reliable solder joints.

The goal of thermal profiling is to optimize the reflow process by balancing heat exposure to avoid issues like component damage, insufficient soldering, or excessive intermetallic compound (IMC) formation. A well-designed thermal profile directly impacts solder joint reliability and overall assembly quality.

Why Thermal Profiling Matters for SMT Assembly

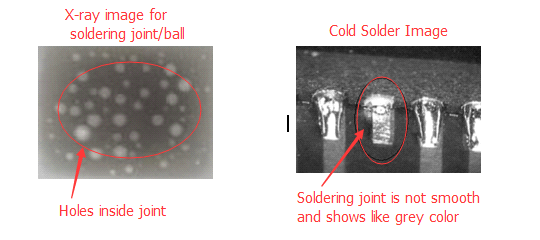

In SMT assembly, the reflow soldering process involves multiple temperature zones, each serving a specific purpose. Without proper thermal profiling, you risk uneven heating, which can lead to defects such as tombstoning, solder voids, or weak joints. Here are the key reasons why thermal profiling is essential:

- Ensures Component Safety: Overheating can damage sensitive components, while insufficient heat can prevent proper soldering.

- Improves Solder Joint Reliability: A balanced profile promotes the formation of optimal intermetallic compounds (IMCs), typically between 1-3 micrometers thick, for strong joints.

- Reduces Defects: Proper profiling minimizes issues like cold solder joints or thermal stress cracks.

- Enhances Production Efficiency: Consistent profiles reduce rework and improve throughput in high-volume manufacturing.

By focusing on SMT assembly thermal profiling best practices, you can achieve consistent results and maintain high-quality standards in your production line.

Key Stages of a Reflow Oven Thermal Profile

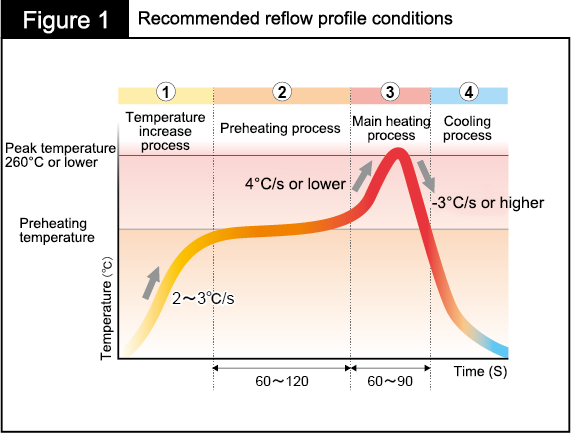

A typical reflow oven thermal profile consists of four main stages: preheat, soak, reflow, and cooling. Each stage plays a vital role in achieving optimal soldering results. Let's break down these stages and explore how to optimize them using reflow oven profiling techniques.

1. Preheat Stage

The preheat stage gradually raises the temperature of the PCB and components to activate the flux in the solder paste. This stage is crucial for removing oxides and preparing surfaces for soldering. A controlled ramp rate, typically between 0.5°C to 2.0°C per second, prevents thermal shock to components.

Optimization Tip: Maintain a steady ramp rate to avoid rapid temperature changes that could cause component stress. Monitor the temperature difference (ΔT) between zones, keeping it below 40°C to ensure uniform heating.

2. Soak Stage (Thermal Equilibrium)

During the soak stage, the temperature is held within a tight range (often 150°C to 180°C for lead-free solder) for a specific duration, usually 60-120 seconds. This allows the thermal gradient across the PCB to stabilize, ensuring that all areas reach similar temperatures before entering the reflow stage.

Optimization Tip: Adjust the soak time and temperature based on the PCB's thermal mass and component density. This step is critical for complex boards with varying thermal requirements.

3. Reflow Stage (Peak Temperature and TAL)

The reflow stage is where the solder paste melts and forms joints between components and the PCB. Two critical parameters to optimize during this stage are the peak temperature in reflow and the time above liquidus (TAL).

- Peak Temperature: This should be set 20-30°C above the liquidus temperature of the solder alloy. For lead-free solder like SAC305, which has a melting point of around 217°C, the peak temperature often ranges from 235°C to 245°C.

- Time Above Liquidus (TAL): TAL refers to the duration the solder remains above its liquidus temperature. A range of 30-90 seconds is typically recommended to allow proper wetting and IMC formation without overheating.

Optimization Tip: Fine-tune the peak temperature and TAL based on your specific solder paste specifications and component tolerances. Excessive TAL can lead to thick IMC layers (above 5 micrometers), which may weaken solder joints.

4. Cooling Stage

The cooling stage solidifies the solder joints and determines the grain structure of the solder. A controlled cooling rate, ideally 2-4°C per second, helps form a fine grain structure for enhanced solder joint reliability. Rapid cooling can cause thermal stress, while slow cooling may result in coarse grain structures that are less durable.

Optimization Tip: Use a controlled cooling zone in the reflow oven to avoid sudden temperature drops. If possible, integrate a nitrogen atmosphere to reduce oxidation during cooling.

SMT Assembly Thermal Profiling Best Practices

To achieve consistent results and minimize defects, follow these SMT assembly thermal profiling best practices. These guidelines are designed to help you create reliable profiles tailored to your specific assembly requirements.

1. Use the Right Tools for Profiling

Invest in high-quality thermal profiling equipment, such as a multi-channel profiler with thermocouples. Attach thermocouples to critical areas of the PCB, including high-density component zones and areas with heavy thermal mass, to capture accurate temperature data.

2. Profile Multiple Boards

Run thermal profiling on multiple boards to account for variations in oven performance and PCB design. This ensures that your profile is robust and adaptable to different production scenarios.

3. Monitor and Adjust Regularly

Reflow ovens can drift over time due to wear or environmental factors. Regularly monitor and adjust your thermal profiles to maintain consistency. Use profiling software to analyze data and detect deviations early.

4. Consider Solder Paste Specifications

Different solder pastes have unique thermal requirements. Always refer to the manufacturer's datasheet for recommended peak temperatures, TAL, and ramp rates. For instance, lead-free solders generally require higher peak temperatures than leaded solders.

Advanced Reflow Oven Profiling Techniques

For engineers looking to take their process to the next level, consider these advanced reflow oven profiling techniques to further optimize performance and reliability.

1. Process Window Index (PWI)

The Process Window Index (PWI) is a statistical measure that evaluates how well your thermal profile fits within the acceptable limits of your process specifications. A lower PWI value indicates a more centered and stable profile. Use profiling software to calculate PWI and make adjustments to keep your process within the optimal range.

2. Design of Experiments (DOE)

Conduct a Design of Experiments (DOE) to systematically test different combinations of peak temperatures, TAL, and ramp rates. This method helps identify the ideal settings for your specific assembly, minimizing trial-and-error and improving efficiency.

3. Nitrogen Atmosphere for Enhanced Results

Using a nitrogen atmosphere in the reflow oven reduces oxidation on solder joints, improving wettability and joint strength. While this increases operational costs, it can be beneficial for high-reliability applications like aerospace or medical devices.

Optimizing Peak Temperature and Time Above Liquidus (TAL)

Fine-tuning peak temperature in reflow and time above liquidus (TAL) optimization is essential for achieving robust solder joints. Here are actionable tips to get it right:

- Peak Temperature: Avoid exceeding the maximum temperature tolerance of sensitive components. If your peak temperature is too high (e.g., above 250°C for lead-free solder), you risk damaging components or causing excessive IMC growth.

- TAL: Aim for a TAL of 40-60 seconds for most lead-free solders. This duration ensures proper wetting without overexposing the assembly to high heat, which can degrade joint reliability.

By carefully balancing these parameters, you can minimize thermal stress and achieve consistent, high-quality solder joints.

Impact on Solder Joint Reliability

Solder joint reliability is the cornerstone of any successful SMT assembly. A poorly optimized thermal profile can lead to weak joints prone to cracking or failure under stress. Here's how thermal profiling directly influences joint reliability:

- Intermetallic Compound (IMC) Formation: Optimal TAL and peak temperature ensure IMC thickness stays within the ideal range of 1-3 micrometers. Thicker IMCs can make joints brittle.

- Grain Structure: Controlled cooling creates a fine grain structure in the solder, improving mechanical strength and resistance to fatigue.

- Thermal Stress: Gradual heating and cooling reduce thermal stress on components and solder joints, preventing cracks or delamination.

By adhering to best practices and continuously refining your thermal profile, you can significantly enhance the long-term reliability of your assemblies.

Common Challenges and How to Overcome Them

Even with the best intentions, thermal profiling can present challenges. Here are some common issues and solutions to help you stay on track:

- Uneven Heating: If certain areas of the PCB heat faster than others, adjust the conveyor speed or zone temperatures to achieve uniform heating.

- Component Sensitivity: For heat-sensitive components, consider a lower peak temperature or shorter TAL, ensuring it still meets soldering requirements.

- Oven Variability: Regularly calibrate your reflow oven and use profiling tools to detect and correct inconsistencies.

Conclusion: Mastering Thermal Profiling for SMT Success

Thermal profiling is a powerful tool for optimizing the reflow soldering process in SMT assembly. By following SMT assembly thermal profiling best practices and leveraging advanced reflow oven profiling techniques, you can fine-tune peak temperature in reflow and achieve time above liquidus (TAL) optimization. The result? Enhanced solder joint reliability and a significant reduction in production defects.

Start by understanding the key stages of a thermal profile, investing in the right tools, and regularly monitoring your process. With a commitment to continuous improvement, you'll be well on your way to achieving peak performance in your SMT assembly line. Trust in the process, and let thermal profiling be your guide to manufacturing excellence.

ALLPCB

ALLPCB