Overview

In an era of major advances in artificial intelligence and the Internet of Things, intelligent video analytics (IVA) is changing video surveillance and analysis by integrating advanced AI technologies. IVA enhances visual intelligence and supports solutions across multiple industries. This article outlines IVA benefits, practical deployment scenarios, and how industrial computers enable these solutions.

What is intelligent video analytics (IVA)?

Intelligent video analytics integrates computer vision, often combined with convolutional neural networks (CNN) or vision transformers (ViT), to analyze raw video streams and generate real-time, actionable insights. IVA forms the basis for several core capabilities:

Object detection and recognition

IVA systems use deep learning models to detect and classify objects within video frames. These models locate objects with bounding boxes and classify them according to pretrained patterns.

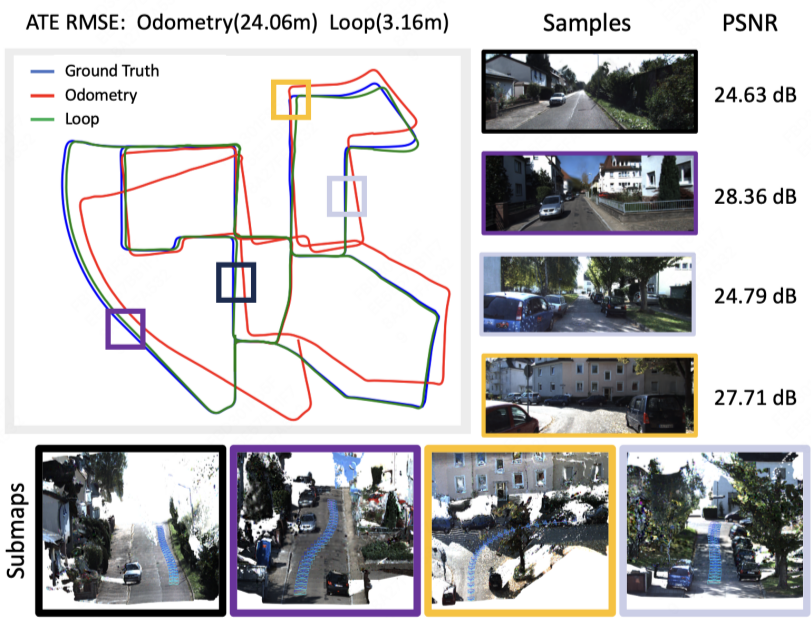

Object tracking

In addition to detection and recognition, IVA employs tracking algorithms to follow object movement across frames, enabling trajectory analysis, behavior prediction, and motion analytics.

Pattern recognition

IVA can identify recurring visual and behavioral patterns over time. These algorithms support statistical modeling and trend analysis for data-driven use cases such as traffic flow estimation and operational inefficiency detection.

Anomaly detection

Using unsupervised or semi-supervised machine learning models, IVA can detect deviations from normal patterns. This enables defect detection, recognition of anomalous activity, and alerts for unauthorized access.

Benefits of IVA in Industry 4.0

IVA automates complex monitoring and asset inspection tasks, improving operational efficiency while reducing human error due to fatigue or oversight. Real-time monitoring is critical for safety and operational continuity. IVA solutions can be deployed at mission-critical sites where maintaining dedicated personnel is difficult or costly, such as remote oil wells or wildfire-prone areas. In Industry 4.0, IVA advances multiple domains:

Manufacturing

- Quality control: Automated visual inspection systems identify asset defects and remove faulty items from production lines, streamlining quality control processes.

- Predictive maintenance: Monitoring equipment and mechanical conditions to optimize maintenance schedules, increasing uptime and extending service life.

Smart cities

- Crowd estimation: AI-enabled cameras analyze pedestrian density in public spaces to inform crowd management, urban planning, and emergency response.

- Disaster management: Enhancing situational awareness by detecting hazards such as fires, floods, and structural damage to accelerate emergency response and resource allocation.

Intelligent transportation

- Tolling: License plate recognition enables seamless, contactless vehicle identification and automated tolling.

- Passenger monitoring: Monitoring activities on public transport to deter unauthorized access, theft, and potential safety threats.

Healthcare

- Medical imaging: AI-assisted image analysis in radiology, pathology, and other imaging domains improves diagnostic support.

- Patient monitoring: Vision-based AI tracks patient movement and vital signs to improve safety, detect falls, and ensure timely medical intervention.

Smart retail

- Shelf monitoring: Automated inventory tracking by detecting stock levels, misplaced items, and empty shelves to optimize restocking and reduce loss.

- Footfall analytics: AI cameras analyze shopping patterns to optimize store layout and improve customer experience and sales performance.

Why edge computing is necessary for IVA

Edge computing is essential for IVA because these applications are latency-sensitive and require processing video data at the source. Traditional cloud computing often falls short in time-sensitive environments due to latency and the inefficiency of transporting large volumes of video data. Processing data locally at the edge reduces reliance on continuous cloud connections, improves data privacy, and optimizes network bandwidth.

Main benefits of edge computing for IVA solutions

- Real-time insights: Immediate response for latency-critical applications such as intrusion and fire detection.

- Data privacy: Localized processing enhances security by minimizing the amount of information relayed to the cloud.

- Bandwidth efficiency: Edge processing substantially reduces bandwidth usage and associated costs compared with cloud-only approaches.

- Hybrid approaches: Actionable insights can be generated at the edge while less time-sensitive data is forwarded to the cloud for aggregated AI training.

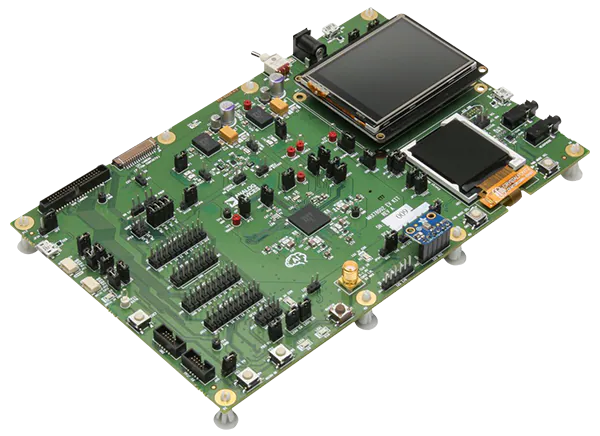

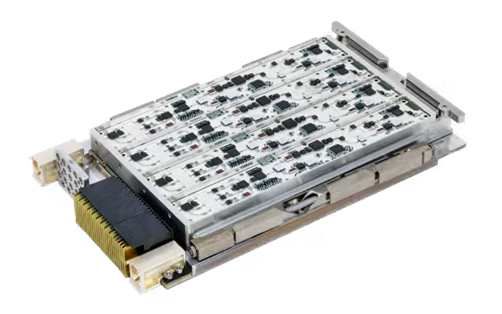

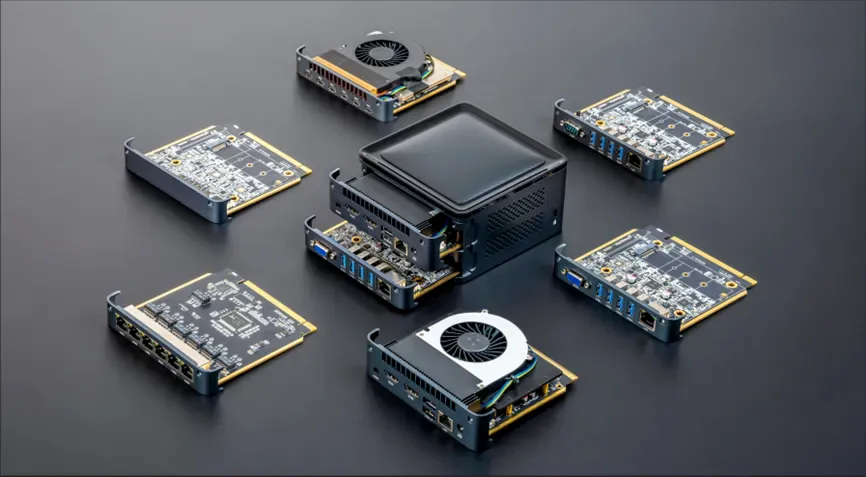

How industrial computers power IVA applications

Industrial computers support IVA applications by providing real-time edge AI processing and integrating data from diverse IoT sensors. Deploying industrial-class systems instead of consumer workstations improves reliability and performance for mission-critical Industry 4.0 deployments.

Key features of industrial computers

- Embedded-focused compute architecture

- NVIDIA Jetson and Intel Core TE processors: Designed for edge computing workloads with optimized processing performance, thermal management, and power management, and with features suited to embedded use cases.

- Edge AI capabilities

- AI acceleration: Dedicated hardware accelerators such as NPUs, TPUs, and GPUs streamline multimodal AI workloads and enable real-time IVA.

- On-device inference: Localizing AI processing reduces response time, improves data security, and ensures operational reliability.

- IoT-centric versatile connectivity

- Advanced and legacy IoT support: Support for a range of IoT-specific interfaces such as RJ45 LAN, RS-232/485 COM, and CAN bus to integrate modern and legacy devices.

- Scalability: Configurable PCIe and M.2 slots enable expansion modules to meet specific deployment requirements.

- Industrial-grade durability

- Fanless and rugged designs: Built for field deployment in harsh industrial environments that are often exposed to dust, debris, extreme temperatures, shock and vibration, and power fluctuations.

- Certification to safety standards: Compliance with standards such as UL listing, FCC, and CE supports reliable deployment.

Edge deployment readiness

- Extended product lifecycle support: Industrial computers provide long-term availability and support to ensure deployment consistency and reduce obsolescence risk.

- Cloud-to-edge certification: Ensure compatibility with hybrid cloud frameworks and platforms, including AWS IoT Greengrass.

Conclusion

IVA is changing industries by enabling real-time video processing and automated decision making. Edge computing and industrial computers provide the required processing power, low-latency response, and deployment reliability for these applications. Edge processing keeps critical data local, reducing dependence on cloud connectivity while improving security and efficiency. Industrial computers deliver robust edge AI performance for mission-critical environments. As AI, IoT, and edge technologies continue to advance, IVA will remain a key driver of smarter and more efficient industrial and commercial applications.

ALLPCB

ALLPCB