Is Modbus TCP the Same as Ethernet?

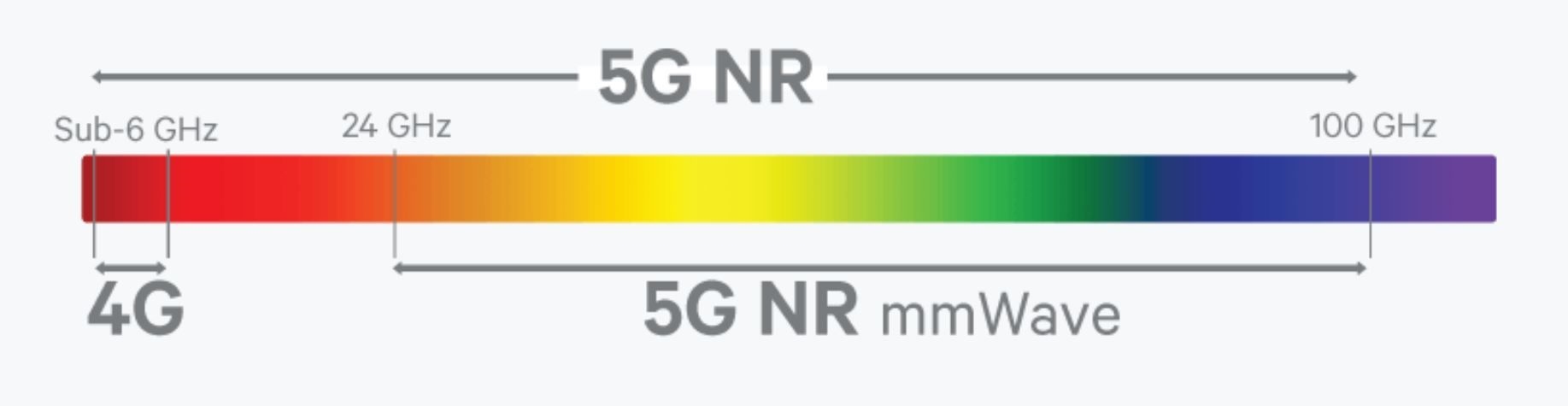

Modbus TCP is an application-layer protocol that operates over Ethernet. It runs on standard TCP/IP transport protocols used by Ethernet, but Modbus TCP and Ethernet are not the same thing. Ethernet is a link-layer and physical-layer technology for local and wide area networking, while Modbus TCP is a communication protocol that uses Ethernet as its transport.

In Modbus TCP, Modbus protocol data units are encapsulated and transmitted via TCP/IP, enabling communication over Ethernet. Thus Modbus TCP can be regarded as an application-layer protocol that uses Ethernet/TCP-IP for transport.

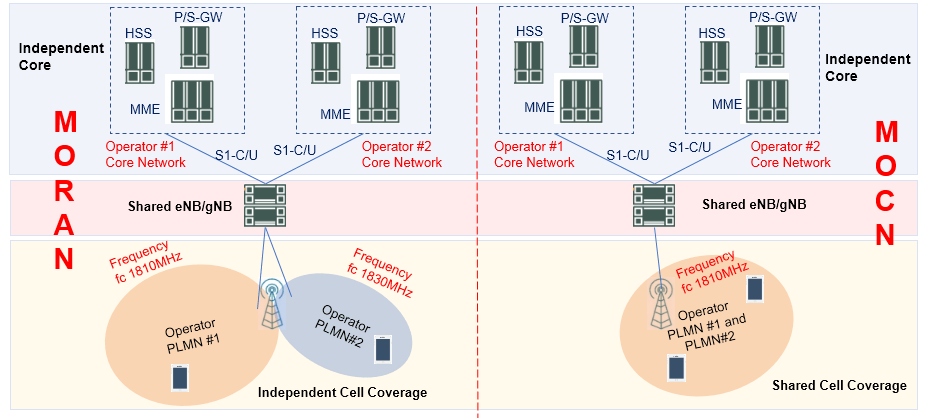

Differences between S7 and PROFINET

S7 and PROFINET are both commonly used communication protocols in industrial automation. S7 is a traditional protocol used in many control systems, while PROFINET is a more recent, Ethernet-based industrial protocol. Key differences include:

- Operation: S7 traditionally uses serial communication methods, whereas PROFINET uses Ethernet-based communication, allowing higher data rates and larger data volumes.

- Throughput: S7 communication speeds are relatively limited and typically below 12 Mbps; PROFINET supports higher speeds and broader bandwidths, including 100 Mbps and above.

- Network topology: S7 networks are relatively simple and often use star topologies. PROFINET supports Ethernet-based mesh and more complex topologies, enabling more advanced network configurations and self-organizing features.

- Real-time performance: PROFINET offers stronger real-time capabilities and can meet tighter real-time control requirements in industrial automation.

Although these protocols differ, they coexist and compete in industrial automation environments. Each protocol has characteristics that make it suitable for particular applications and requirements.

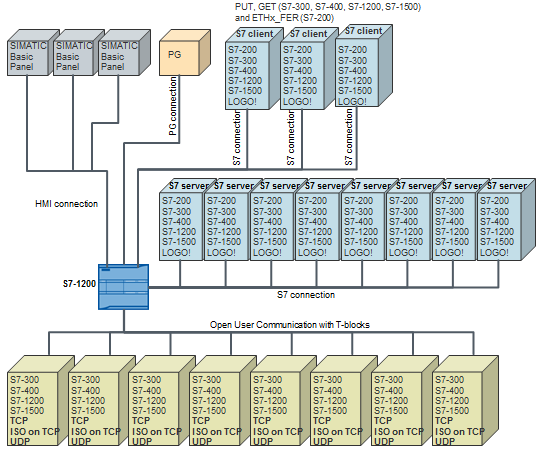

S7 Communication Protocol Overview

The S7 communication protocol is Siemens' standard protocol for communication among S7-series PLCs. It is primarily a serial communication protocol, commonly using RS485 or RS232 as the physical medium, and it supports point-to-point and multipoint communication. S7 enables data exchange and mutual control between PLCs. It supports coordinated transfer of motion, timing, alarm, and other data between master and slave devices and is widely used in industrial control systems, automated production lines, and device I/O control.

The S7 protocol is generally structured into four layers:

- Physical layer: Commonly RS485 and RS232; higher-speed media such as fiber optics or Ethernet can also be used.

- Data link layer: Includes frame start and end flags, control information, and mechanisms for framing, checksum, and error recovery.

- Transport layer: Manages data transfer sequencing and communication control flow, including acknowledgments and resets.

- Application layer: Implements application functions such as read/write operations and data requests.

In summary, the S7 communication protocol is a specialized protocol widely used for data transfer and control between PLCs. Its strengths include reliability and support for long-distance communication, making it suitable for many industrial control scenarios.

ALLPCB

ALLPCB