Overview

Commercial and industrial energy-storage small to medium container systems typically have capacities of about 250 kWh to 2 MWh. The power distribution design is as follows.

Power Distribution

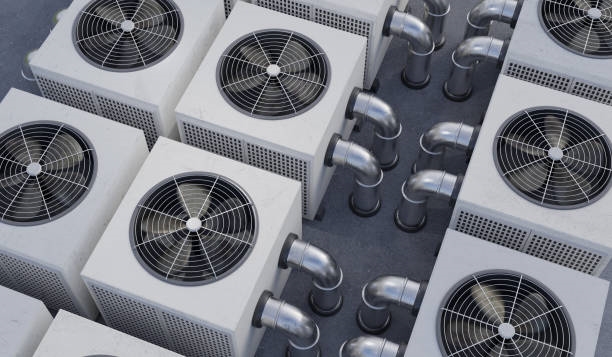

Internal container loads are mainly supplied by mains power. This container is equipped with an integrated AC distribution cabinet. The enclosure's three-wire power input is derived from the AC side of the energy-storage converter. The distribution cabinet is designed to ensure three-phase load balance. Separate circuits are provided for air conditioning, container fans, lighting, and other loads.

The container distribution system connects to a secondary backup power source to supply fire protection, BMS, stack control, EMS, and similar systems during mains outages, ensuring power reliability. Outlet provisions are reserved. Consider a UPS rated about 2 kVA with 30 minutes of backup time.

Lighting

The container lighting system uses explosion-proof lamps rated at 220 V, 50 Hz, and operable between -40°C and 50°C. The lighting system is designed for easy installation and maintenance, and a control switch for all interior lighting is located near each door. To ensure safe evacuation while the lighting system is operating, lighting fixtures are installed at every interior door. Night-time lighting is installed above external maintenance doors; these lights are powered independently via a dedicated circuit breaker inside the container, and the breaker can be manually switched off.

Grounding and Mounting

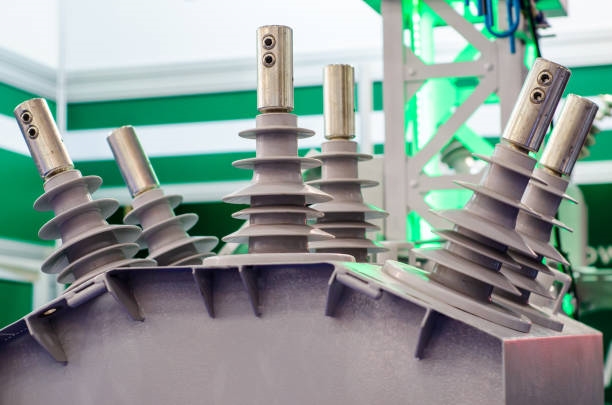

The container meets basic crane lifting installation requirements and offers both bolted and welded fixing methods. Bolt and weld points are reliably connected to the container's non-functional conductive elements, such as the metal shell. Provide at least two grounding points to the user in the form of copper busbars that meet stringent electrical standards. Primary and secondary equipment grounding inside the container are separated, using copper busbars. Ensure two reliable grounding points for equipment and the enclosure, and reserve a connection point for the enclosure to the site grounding system.

ALLPCB

ALLPCB