Overview

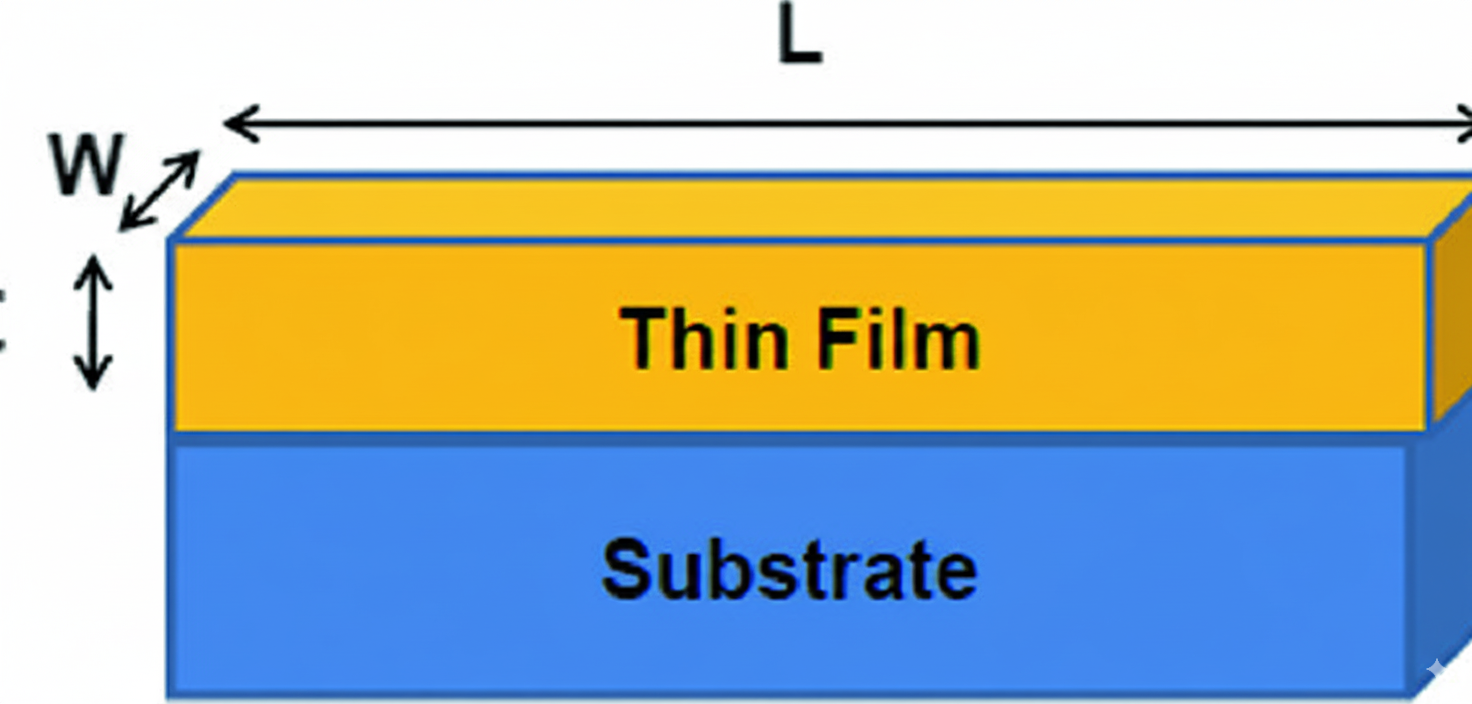

In semiconductor manufacturing, film thickness has a significant impact on device performance and quality. Thickness influences optical properties such as refraction, reflection, and transmission, and can produce quantum size effects that alter electronic, optical, and magnetic properties. Accurate measurement and control of film thickness are essential for optimizing device performance, improving production yield, and ensuring reliability.

Four-point probe method

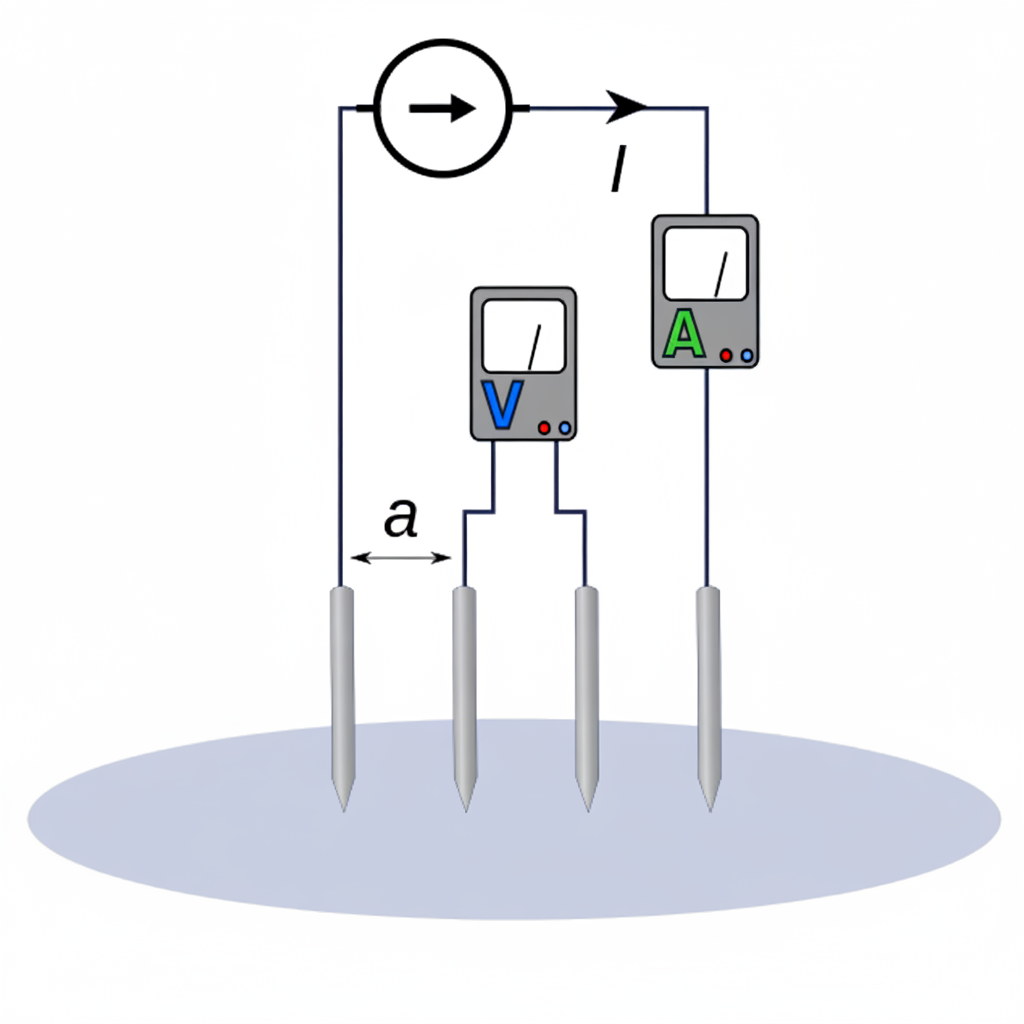

The four-point probe method measures the sheet resistance of a thin film. Four equally spaced probes contact the material under test. The outer two probes source current while the inner two probes measure the resulting voltage drop on the sample surface. Probes are typically placed near the wafer center for a localized measurement.

After obtaining the sheet resistance, film thickness t can be derived using the appropriate relationship for resistivity, sheet resistance, and any correction factors applicable to the probe spacing and sample geometry.

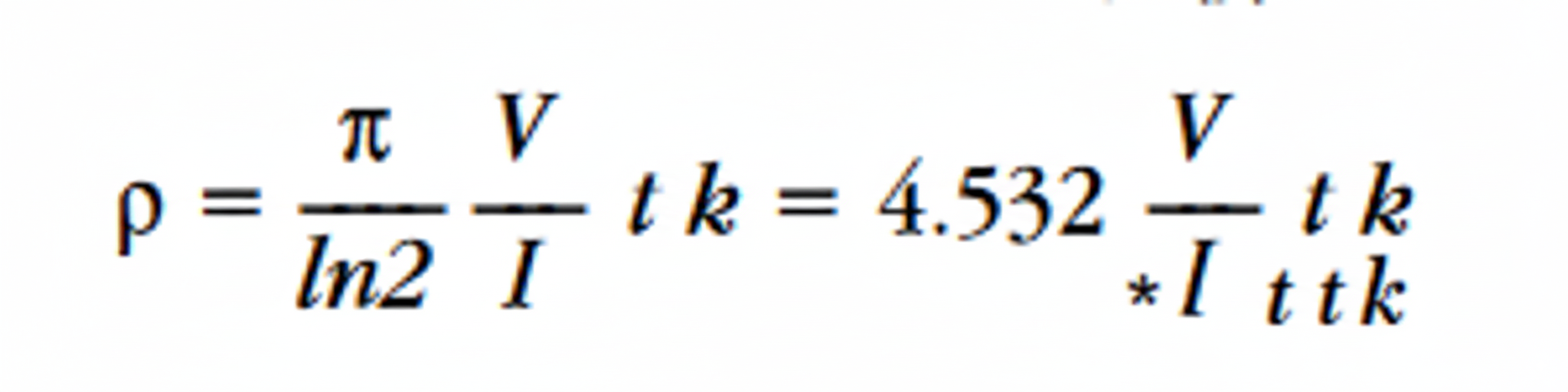

Notation: ρ = bulk resistivity (Ω·cm). V = measured voltage (V). I = measured current (A). t = sample thickness (cm). k = correction factor. Typical application: measuring thickness of opaque conductive films.

Ellipsometry

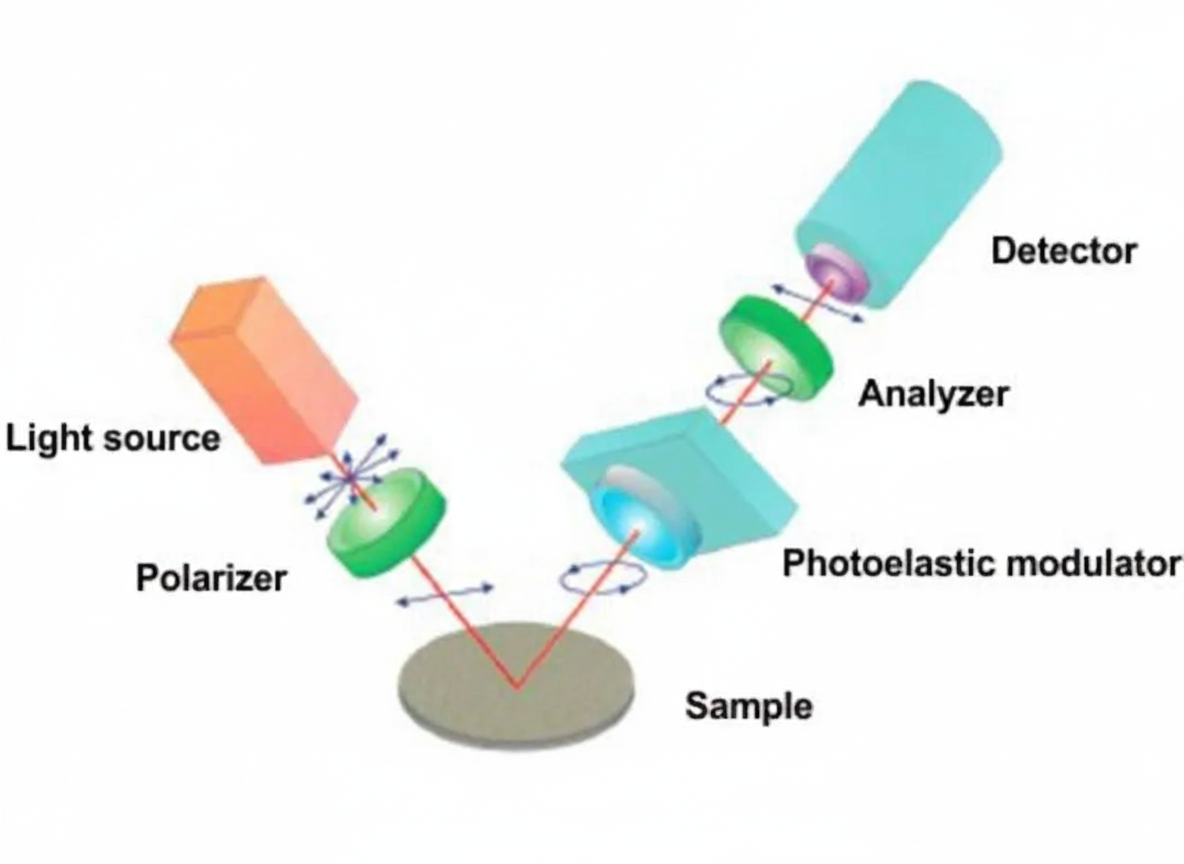

Ellipsometry is a non-contact, non-destructive optical technique that infers film properties by measuring the change in polarization of light reflected from a surface. It is commonly used to determine film thickness and optical constants.

Typical ellipsometer components:

- Light source: provides monochromatic or quasi-monochromatic polarized light (lasers or filtered lamps).

- Analyzer: measures the polarization state of the reflected light, often implemented with polarizers and compensators.

- Detector: records the intensity after the analyzer for further analysis.

When linearly polarized light strikes a sample surface, the reflected light generally becomes elliptically polarized due to the sample's refractive index and extinction coefficient. By measuring the change in polarization and fitting to optical models, one can extract film thickness and optical constants. Typical application: measuring transparent films and metal films thinner than 50 nm.

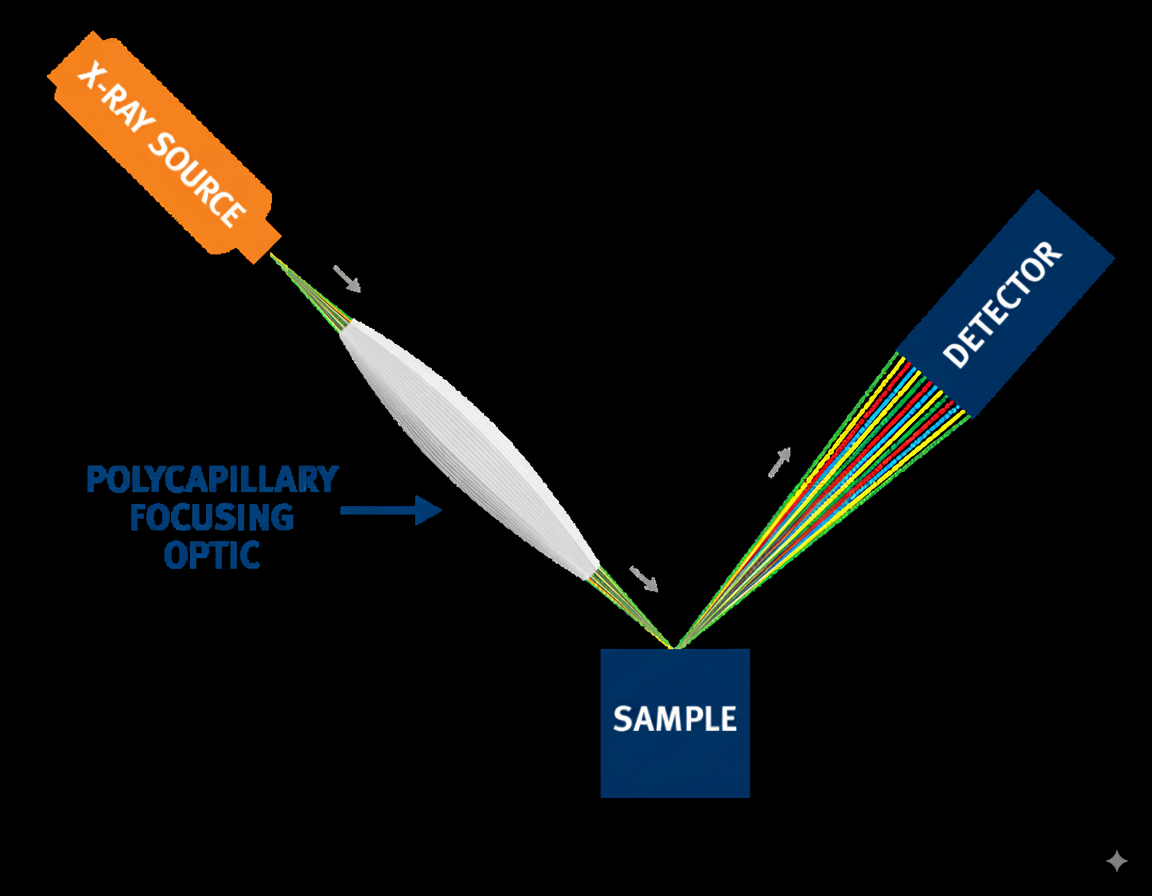

X-ray fluorescence (XRF)

X-ray fluorescence (XRF) is a non-destructive elemental analysis technique capable of detecting elements from boron to uranium. An XRF analyzer measures the characteristic fluorescent X-rays emitted by a sample when excited by a primary X-ray source.

Each element in the sample emits a unique set of characteristic X-ray lines. By comparing the measured XRF spectrum to reference data, XRF provides qualitative and quantitative information about material composition.

Typical application: identifying alloys, detecting impurity elements, analyzing precious metals, and determining film mass and thickness where applicable.

ALLPCB

ALLPCB