Overview

IoT is becoming increasingly prominent across many applications. One such application is heating, ventilation, and air conditioning (HVAC) systems used in residential, industrial, and commercial facilities.

HVAC systems are complex infrastructure. Failure of a single component or function can lead to higher energy consumption and increased maintenance costs. As a result, original equipment manufacturers (OEMs) are adopting IoT to optimize HVAC performance and reduce maintenance expenses. IoT solutions for HVAC provide operational visibility and improved monitoring of energy use.

Below are reasons why HVAC manufacturers should adopt IoT.

Why OEMs Should Connect HVAC Equipment to IoT

HVAC systems handle heating, cooling, and ventilation demands. Even minor component failures can affect OEM profitability, so preventing issues before they occur is a top priority for facility providers. IoT-enabled HVAC systems connected to smart thermostats or room controllers collect data and share it with cloud-based analytics platforms to monitor environmental changes and enable predictive maintenance. Connected solutions communicate with HVAC equipment to dynamically adjust temperatures as needed and generate alerts when abnormal device behavior is detected.

For example, many HVAC systems fail under extreme heat, triggering urgent repair requests. In such cases, smart HVAC systems can generate alerts for signs of degradation and notify users to take action before faults occur.

In the U.S., several utilities offer demand response programs based on the CTA-2045 standard. These programs provide incentives when end users turn off large loads or reduce usage during peak demand. CTA-2045 is a modular communication interface (MCI) that enables communication with residential devices for energy management. Demand-response systems based on CTA-2045 allow utilities to use end-user device load when grid demand is lower. This capability is enabled by introducing IoT into traditional HVAC systems.

In short, IoT can enhance the value proposition of HVAC products.

How a Smart HVAC IoT Ecosystem Works

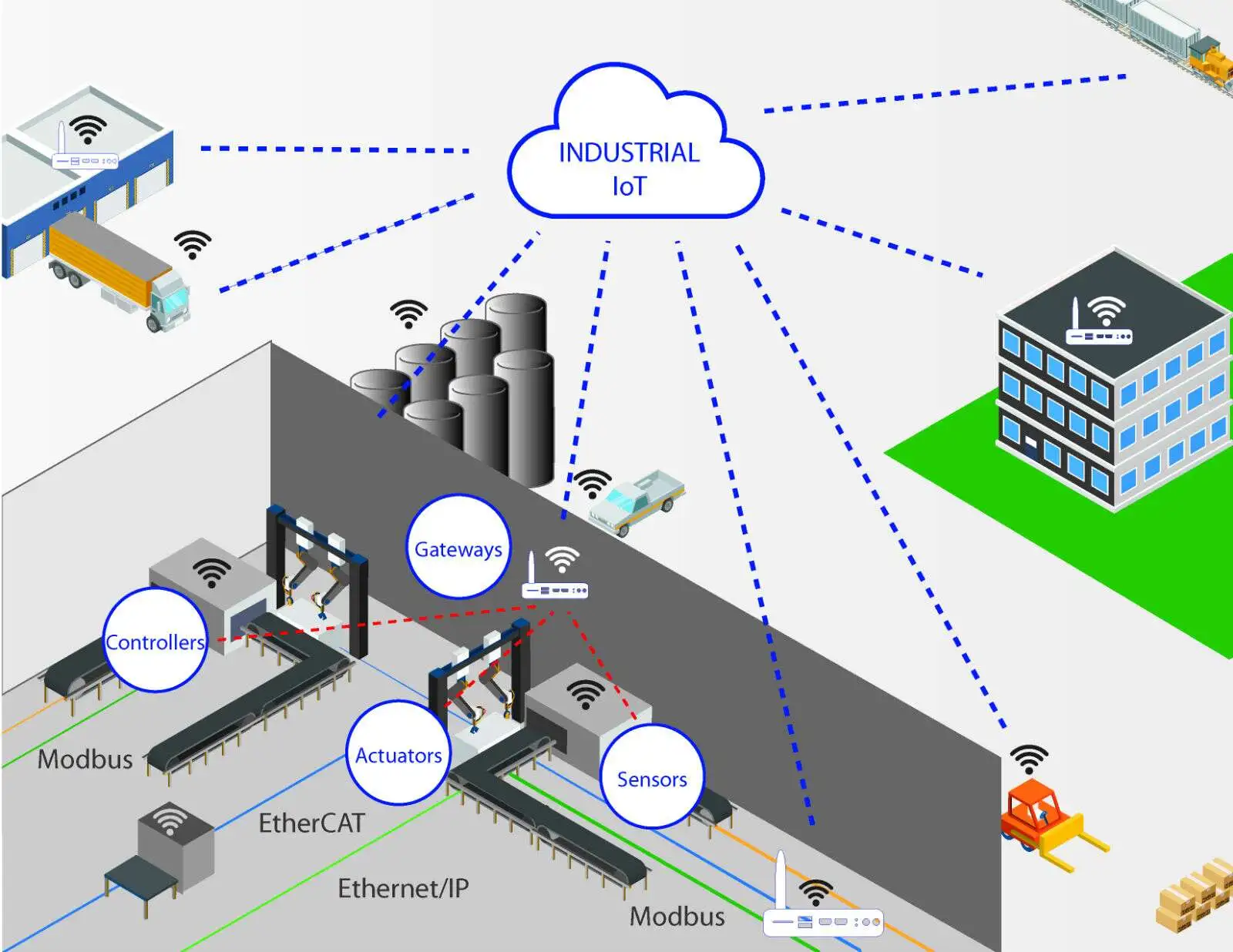

A typical HVAC system includes sensors and actuators. Devices controlling the HVAC are equipped with wireless radios that send data to the cloud via a gateway. Protocols are tunneled through the gateway to share data directly with the cloud. Users can monitor HVAC performance from the cloud through portals, and mobile devices allow local and remote access and management of HVAC equipment.

HVAC software collects information from various sensors, processes the data as needed, and forwards it to the cloud for further analysis.

The cloud analytics platform is responsible for filtering and analyzing data and sharing insights with other systems when required. Learning algorithms use database information to support predictive maintenance, optimize energy use, and enable remote control of HVAC systems. Faults, alerts, and events are also reported to remote system administrators.

Example: CTA-2045-Based Demand Response Scenario

A manufacturer may develop a CTA-2045-compliant, energy-saving, demand-response (DR) ready product.

This CTA-2045-based solution aims to increase grid reliability and efficiency by adding products that can respond to changing grid conditions.

Universal Communication Module (UCM) - an AC module per CTA-2045 - is suitable for smart grid devices (SGDs). An SGD can be a CTA-2045-compliant HVAC system, a heater, or other consumer product.

The UCM is configured via BLE using a mobile device running the customer mobile app. After configuration, it connects to the customer cloud via Wi-Fi or cellular (LTE Cat M1). The UCM uses MQTT to communicate with the cloud. Once connected, the cloud can send JSON objects that the UCM forwards to the SGD.

Utilities initiate DR commands from a DR portal into the customer cloud. These DR commands are parsed by the UCM, forwarded to the SGD, and the SGD takes the necessary actions according to the DR command. In response, the SGD sends a reply to the UCM, which relays it back to the cloud.

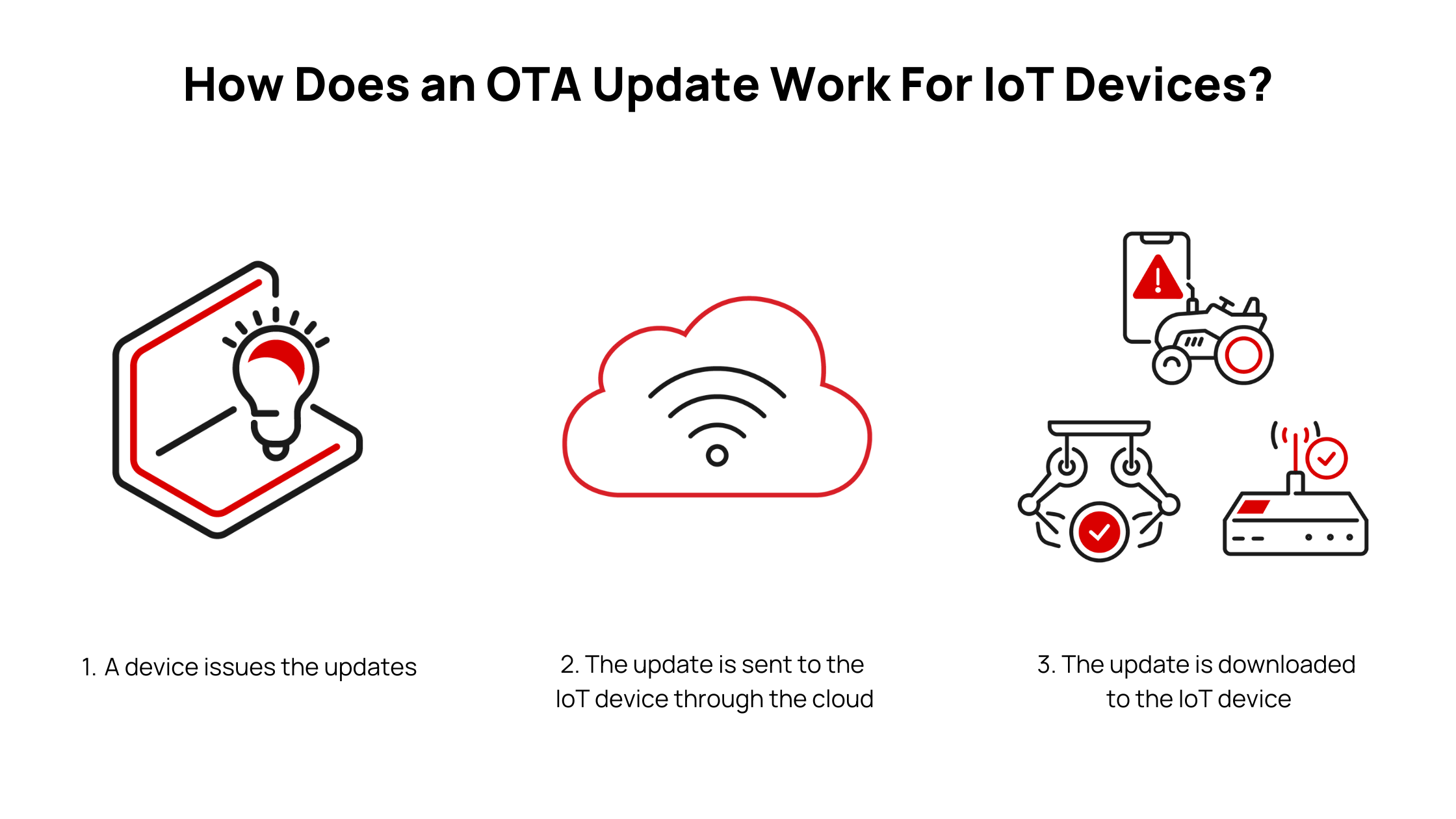

The UCM also supports OTA firmware upgrades via the customer cloud.

The user interface consists of LEDs that indicate different alarm states, internet connectivity, and DR status to provide an intuitive local view. The UCM also supports buttons to start configuration, acknowledge alarms, and suspend demand response in accordance with CTA-2045.

How IoT Helps HVAC Manufacturers Improve Product Performance

- Real-time monitoring: Manufacturers and OEMs gain an accurate picture of device performance by collecting real-time operational data.

- Reduced power consumption: HVAC systems collect operational data and move it to the cloud for analysis. Cloud analytics support informed decisions, enabling efficient energy management and cost savings.

- Predictive maintenance: IoT enables condition-based service rather than fixed-interval servicing, helping detect issues before major failures occur. This saves repair costs and extends product life.

Considerations When Designing IoT-Connected HVAC Systems

Follow best practices when designing smart HVAC systems, including considerations for scalability, potential interference, installation methods, network security, safety measures for HVAC interfaces, range, automatic recovery, and safe shutdown.

IoT Security

Plan for end-to-end security so that data flows are not compromised. This includes securing the connected devices themselves, the cloud, the mobile or web apps used to control the products, and access by any authorized parties.

Use Established Hardware Platforms

When selecting a hardware platform for a connected product, choose mature vendors rather than only low-cost options. Verified hardware platforms help ensure reliable wireless connectivity. Mature vendors typically provide well-tested wireless stacks, compatibility, firmware support, certification and service provider registration assistance, and strong security support.

Secure OTA Capability

IoT devices deployed in the field must support secure over-the-air updates. OTA updates improve performance and allow new features to be added while devices remain with end users. Secure OTA is necessary because device security policies themselves are often updated via OTA.

IoT is a major driver of HVAC system innovation. HVAC IoT devices offer significant benefits in energy saving, demand forecasting, efficiency improvement, and predictive maintenance. Data analytics and machine learning are expected to reshape the HVAC IoT landscape.

ALLPCB

ALLPCB