Overview

The yaw system of a wind turbine can be implemented in several ways. The following are four common approaches:

- Conventional yaw system: A conventional yaw system uses an electric motor or hydraulic drive to actuate the turbine's yaw mechanism and align the nacelle with the wind. This approach relies on mechanical transmission to perform steering adjustments and is widely used for its relative simplicity.

- Pitch-based yaw: Some turbines implement yaw control by adjusting blade pitch. When wind direction changes, the control system alters blade pitch to generate a yawing moment that reorients the rotor toward the wind. This method can provide faster response to changing wind direction by leveraging blade adjustments.

- Active yaw control: Active yaw control uses wind speed and wind direction sensors to obtain real-time atmospheric data, then applies control algorithms to actively adjust the nacelle orientation. Advanced control algorithms can improve yaw accuracy and the turbine's overall performance and stability.

- GPS-assisted yaw: Some turbines use GPS-assisted yaw control by incorporating positioning information to refine yaw alignment. GPS data can complement wind sensors to help the yaw system more accurately orient the turbine for improved wind capture.

Yaw Drive Unit

Yaw rotation is typically carried out by gear pairs, which may be external or internal tooth engagements. Brakes can be either normally closed or normally open. A normally closed brake is locked when there is no hydraulic pressure or electromagnetic actuation, while a normally open brake is released when no actuation is present. The yaw drive can be powered by an electric motor or a hydraulic motor.

The drive assembly usually comprises the drive motor or hydraulic motor, a gearbox, the driving gear, and a mechanism for adjusting gear backlash. Because yaw speed is low, the gearbox is commonly a multi-stage planetary reducer or a combination of worm gear and planetary stages. Reducers often use involute-profile four-stage planetary cylindrical gear transmission. The yaw driving gear must match the yaw ring gear, and the drive torque must exceed the maximum resisting torque. Resisting torque includes bearing friction torque, damping torque from the damping mechanism, yaw resistance due to aerodynamic and mass eccentricity of the rotor, and any additional rotor torque.

Yaw Brake and Dampers

Yaw brakes are available in centralized, distributed, active, and passive configurations. During yaw maneuvers, the brake must provide a stable resisting torque with deviation from the design value less than 5%, and the braking process should be free of abnormal noise. Under rated load at closure, the contact area between the brake pad and brake disc should be at least 50% of the design area; any clearance between the pad edge and the caliper should not exceed 0.5 mm at any point.

Brake pads on the caliper are made from dedicated friction materials, typically copper-based or iron-based powder metallurgy. Copper-based powder metallurgy is commonly used for wet brakes, while iron-based powder metallurgy is more common for dry brakes. Brakes should include an automatic compensation mechanism to maintain braking torque and yaw damping torque stability as pads wear.

Yaw System Components

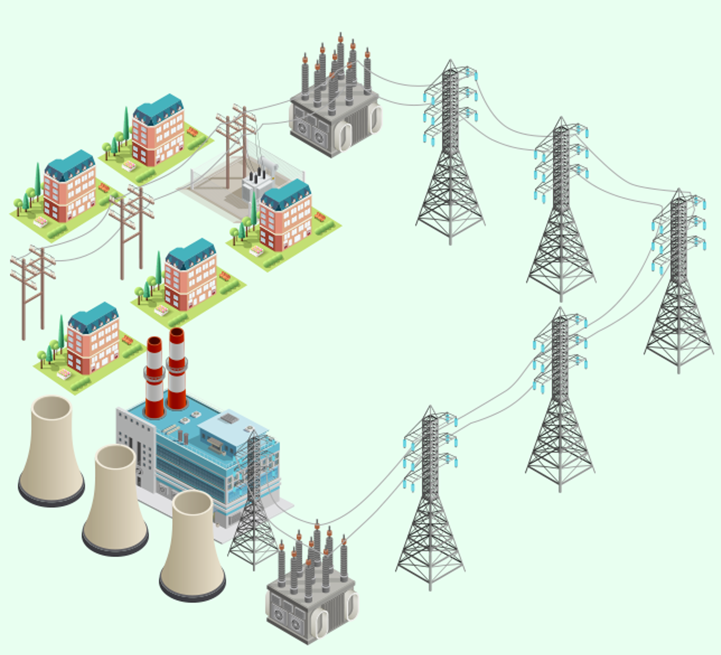

The yaw system is a critical part of a wind turbine whose primary role is to keep the rotor facing the wind to maximize energy capture. Typical components include:

- Wind speed and wind direction sensors: Measure local wind speed and direction and send data to the controller. Accurate measurements are a prerequisite for correct yaw operation.

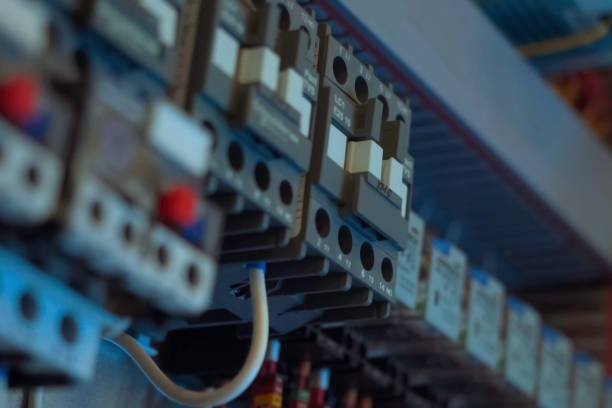

- Controller: The core of the yaw system. It receives sensor data and generates control signals based on configured modes and strategies. Controllers are typically implemented with microprocessors or programmable logic controllers and use algorithms to manage yaw behavior.

- Yaw drive system: Executes yaw adjustments to orient the rotor. It generally includes the drive actuator, transmission elements, yaw shaft, and yaw ring.

- Yaw angle sensor: Measures rotor yaw angle and feeds it back to the controller for monitoring and adjustment to ensure correct alignment with wind direction.

- Electrical system: For electric-motor-driven yaw systems, this includes power supply, motor drive, and interfaces. The electrical system supplies the power and control signals required by the yaw drive.

These components work together to align the rotor with wind direction based on wind speed, direction, and yaw angle data, thereby improving energy capture and turbine stability through automatic orientation adjustments.

ALLPCB

ALLPCB