In the world of modern electronics, the process of Electronics PCB assembly is the backbone of creating functional devices. Whether you're designing a smartphone, a medical device, or industrial equipment, understanding how printed circuit boards (PCBs) are assembled using advanced machinery is crucial. This blog post dives deep into the intricacies of PCB machine assembly, covering topics like smart electronic microprocessors, types of mounting technologies such as Through-Hole, and techniques like Solder Paste Screening. By the end of this guide, you'll have a clear understanding of how these processes come together to build reliable and efficient electronic systems.

What Is Electronics PCB Machine Assembly?

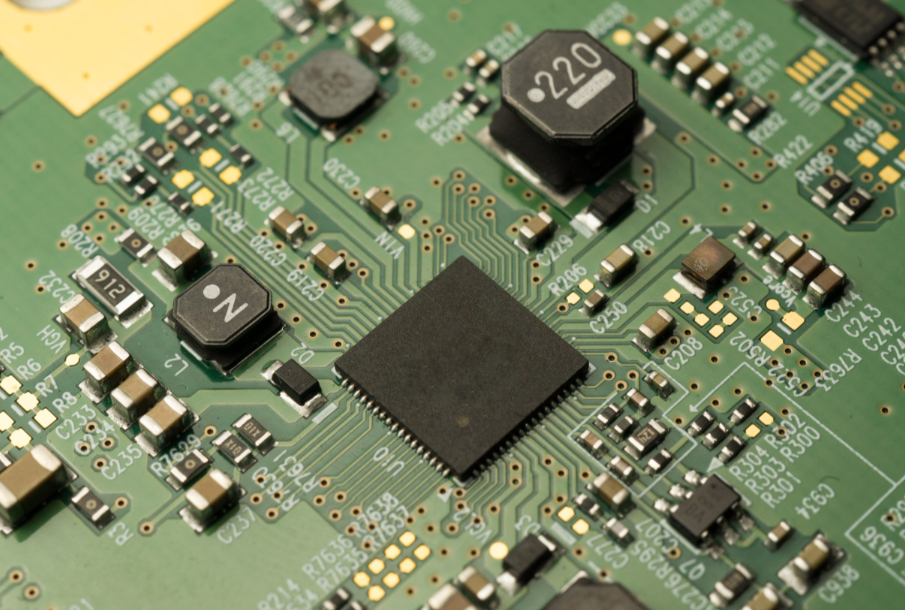

Electronics PCB assembly refers to the process of mounting electronic components onto a Printed Circuit Board (PCB) to create a functional circuit. This process is often automated using specialized machines to ensure precision, speed, and consistency. From placing tiny smart electronic microprocessors to soldering components in place, PCB machine assembly transforms a bare board into a working electronic device. It's a critical step in manufacturing everything from consumer gadgets to complex industrial systems.

In this blog, we'll explore the key stages of PCB assembly, the technologies involved, and the machinery that makes it all possible. Whether you're an engineer, a hobbyist, or a business owner looking to understand the production process, this guide will provide actionable insights into the world of PCB assembly.

The Importance of PCB Assembly in Electronics Manufacturing

PCBs are the foundation of nearly every electronic device. They provide the physical structure and electrical connections needed for components like resistors, capacitors, and microprocessors to function. Without precise assembly, even the most advanced designs can fail. PCB machine assembly ensures that components are placed accurately and soldered securely, minimizing errors and maximizing performance.

For instance, in high-speed applications, improper placement of a microprocessor can lead to signal delays or interference. Modern assembly machines can place components with an accuracy of less than 0.01mm, ensuring that even the smallest parts are positioned perfectly. This precision is especially important for smart electronic microprocessors, which often have hundreds of tiny connection points packed into a space smaller than a fingernail.

Key Stages of Electronics PCB Machine Assembly

The PCB assembly process involves several stages, each performed by specialized machines designed to handle specific tasks. Below, we'll break down the most important steps in detail.

1. Solder Paste Screening: The Foundation of Assembly

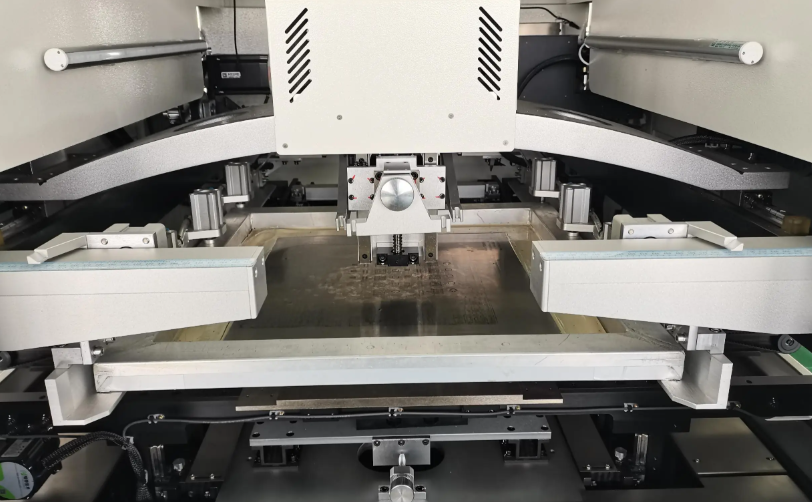

The first step in PCB assembly is applying solder paste to the board using a technique called Solder Paste Screening. Solder paste is a mixture of tiny solder particles and flux, which helps components stick to the board during soldering. This process is done using a solder paste printer, a machine that applies the paste through a stencil.

The stencil, often made of stainless steel, has tiny openings that match the layout of the PCB. The machine spreads the solder paste over the stencil, ensuring that it only goes where components will be placed. This step is critical because uneven or insufficient paste can lead to weak solder joints, causing components to fail. Modern solder paste printers can achieve a deposition accuracy of ±0.025mm, ensuring consistent results even on densely packed boards.

2. Component Placement with Pick-and-Place Machines

Once the solder paste is applied, the next step is placing the components onto the PCB. This is done using pick-and-place machines, which are robotic systems capable of handling thousands of components per hour. These machines use vacuum nozzles to pick up components from reels or trays and place them onto the board with incredible precision.

For example, a high-speed pick-and-place machine can position up to 200,000 components per hour, making it ideal for mass production. This is especially important for placing smart electronic microprocessors, which often use complex packaging like Ball Grid Arrays (BGAs) with connection points spaced less than 1mm apart. The accuracy of these machines ensures that every pin aligns perfectly with the solder paste on the board.

3. Soldering: Securing Components to the Board

After components are placed, the PCB goes through a soldering process to create permanent electrical connections. There are two main soldering methods used in machine assembly: reflow soldering and wave soldering. Reflow soldering, commonly used for surface mount components, involves heating the board in a reflow oven to melt the solder paste. Wave soldering, often used for through-hole components, passes the board over a wave of molten solder.

Reflow ovens typically operate at temperatures between 220°C and 260°C, depending on the type of solder used. This controlled heating ensures that the solder melts evenly without damaging sensitive components. For high-density boards with microprocessors, manufacturers often use X-ray inspection after soldering to check for hidden defects in solder joints.

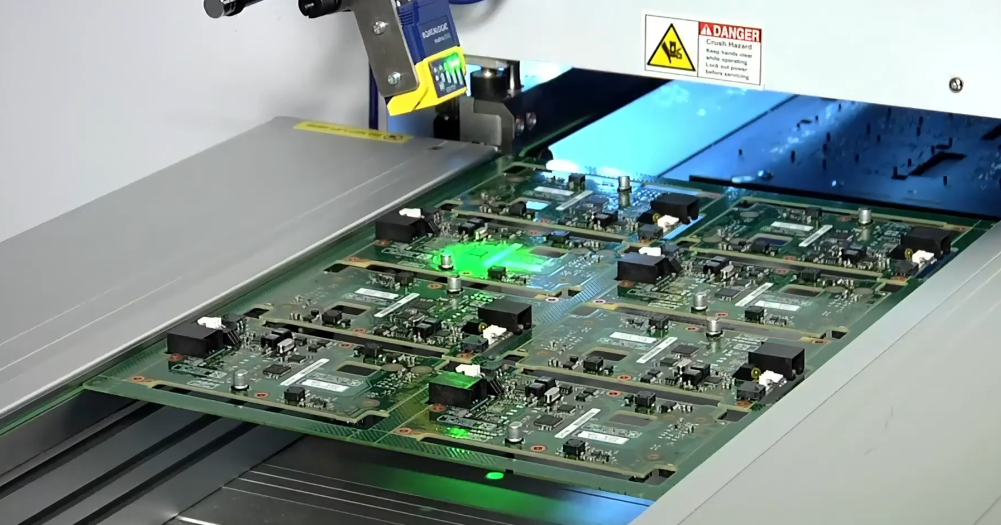

4. Inspection and Testing

Once soldering is complete, the assembled PCB undergoes rigorous inspection and testing to ensure quality. Automated Optical Inspection (AOI) machines use cameras to check for misaligned components, missing parts, or soldering defects. For complex assemblies with hidden joints, such as those under microprocessors, X-ray inspection is used to verify connections.

In-circuit testing (ICT) is also performed to check the electrical functionality of the board. This step can detect issues like short circuits or open connections, ensuring that the PCB will work as intended. With defect rates in high-quality assembly lines often below 0.1%, these testing methods are essential for maintaining reliability.

Types of Mounting Technologies in PCB Assembly

PCB assembly relies on different mounting technologies to attach components to the board. The two primary methods are Through-Hole and Surface Mount Technology (SMT). Each has its own advantages and is suited to specific applications. Let's explore these types of mounting technologies in detail.

Through-Hole Technology (THT)

Through-Hole technology involves inserting component leads through holes drilled into the PCB and soldering them on the opposite side. This method has been used for decades and is known for its durability and reliability. Through-Hole components are often used in applications where mechanical strength is important, such as in power supplies or industrial equipment.

One key advantage of Through-Hole is that it can handle higher power levels, making it ideal for components like large capacitors or connectors. However, it requires more space on the board and is slower to assemble compared to SMT. In modern assembly lines, Through-Hole components are often soldered using wave soldering machines, which can process multiple boards quickly.

Surface Mount Technology (SMT)

Surface Mount Technology, or SMT, is the dominant method in modern PCB assembly. Unlike Through-Hole, SMT components are placed directly onto the surface of the board, with solder paste holding them in place before reflow soldering. This technology allows for smaller components and denser board layouts, which is why it's used for smart electronic microprocessors and other compact devices.

SMT can reduce board size by up to 50% compared to Through-Hole, making it perfect for smartphones, wearables, and other miniaturized electronics. High-speed pick-and-place machines are designed specifically for SMT, enabling rapid assembly of boards with thousands of components. However, SMT connections are less mechanically robust, so they may not be suitable for high-stress environments.

The Role of Smart Electronic Microprocessors in PCB Assembly

Smart electronic microprocessors are the brains of many modern devices, controlling everything from data processing to user interfaces. These tiny chips are often the most complex components on a PCB, with hundreds or even thousands of connection points. Assembling them requires extreme precision, which is why advanced machinery is essential.

For example, microprocessors often use Ball Grid Array (BGA) packaging, where tiny solder balls on the underside of the chip connect to the PCB. Placing a BGA component requires alignment accuracy of less than 0.05mm to ensure every ball makes contact with the solder paste. After soldering, X-ray inspection is often used to check for voids or misalignments in the solder joints, as even a single poor connection can cause the device to fail.

Advanced Machinery in PCB Assembly

The efficiency and accuracy of PCB assembly depend heavily on the machinery used. Modern assembly lines are equipped with a range of specialized equipment, each designed for a specific task. Below are some of the key machines involved:

- Solder Paste Printers: These apply solder paste with high precision, ensuring consistent coverage for soldering.

- Pick-and-Place Machines: Capable of placing thousands of components per hour, these are the workhorses of SMT assembly.

- Reflow Ovens: These heat the PCB to melt solder paste, creating strong electrical connections.

- Wave Soldering Machines: Used for Through-Hole components, these pass the board over a wave of molten solder.

- Inspection Systems: AOI and X-ray machines detect defects, ensuring quality control.

Investing in high-quality machinery can significantly reduce defect rates and improve production speed. For instance, a top-tier pick-and-place machine can achieve placement speeds of over 100,000 components per hour, a critical factor for large-scale manufacturing.

Challenges in Electronics PCB Machine Assembly

While machine assembly offers many benefits, it also comes with challenges. One common issue is component miniaturization. As devices get smaller, components like 0201 resistors (measuring just 0.6mm x 0.3mm) become harder to place accurately. Even a slight misalignment can lead to defects, requiring advanced machinery and skilled operators.

Another challenge is thermal management during soldering. High temperatures in reflow ovens can damage sensitive components if not controlled properly. Manufacturers often use thermal profiling to monitor temperatures across the board, ensuring they stay within safe limits (typically below 260°C for most components).

Conclusion: Mastering Electronics PCB Machine Assembly

Understanding Electronics PCB assembly is essential for anyone involved in electronics design or manufacturing. From Solder Paste Screening to the placement of smart electronic microprocessors, every step of the process requires precision and expertise. By leveraging advanced machinery and mastering types of mounting technologies like Through-Hole and SMT, manufacturers can create reliable, high-performance devices that meet the demands of today's market.

Whether you're designing a simple circuit or a complex system, the principles of PCB machine assembly remain the same: accuracy, quality, and efficiency. With the right tools and knowledge, you can ensure that your Printed Circuit Board (PCB) assemblies are built to last. Stay informed about the latest advancements in assembly technology to keep your production processes at the cutting edge.

ALLPCB

ALLPCB