Introduction

The wearable health, wellness, and fitness market is evolving rapidly, with new products appearing frequently. The availability of low-cost, low-power microcontrollers and widespread wireless connectivity has helped drive growth in portable and personal fitness monitoring devices.

For design teams, developing a new health or fitness device often means compressing functionality that once resided in bedside units into a form factor that is easy to carry or that can be worn on the wrist. Market speed raises challenges: spending months evaluating a device and developing custom hardware to validate a concept can delay a product or cause it to miss the market window entirely.

This article examines two common wearable health device examples and identifies the sensing, processing, and communication features they share. It then introduces a reference design platform that includes these necessary features and addresses many design issues associated with wearables.

Portable medical device examples

What components form the core of these portable medical and fitness designs? Here are a few examples.

Pulse oximeter

A pulse oximeter measures arterial oxygen saturation to ensure adequate oxygenation. Typical users include people with respiratory issues, patients under anesthesia, and premature infants or neonates.

Pulse oximetry is noninvasive. The most common sensing method transmits red and infrared (IR) light through a finger, toe, or ear and measures the ratio of received intensities at the two wavelengths. Oxygenated hemoglobin absorbs more infrared light than red light; deoxygenated hemoglobin absorbs more red light than infrared.

In a typical design, a finger-mounted clip contains two LEDs as transmitters, a photodiode sensor to measure absorbance, and a serial link for transmitting a unique sequence identifier (see figure).

The main unit contains a microcontroller that receives and processes analog sensor data, drives the LEDs, reports results via a display, and transmits results over a wired or wireless link.

Clips typically connect to the host by cable, although some oximeters integrate all electronics into a single finger-mounted device.

Fitness monitors

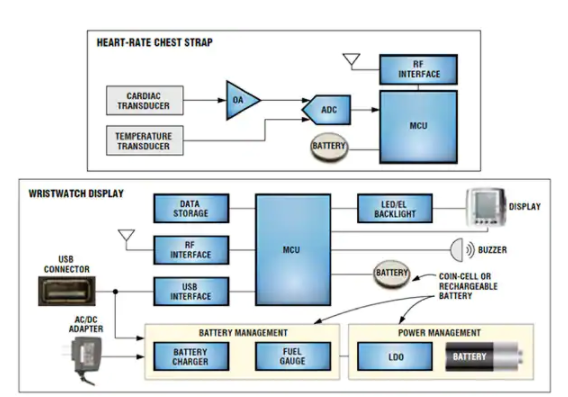

Fitness monitors track and record physical activity to help improve health. Typical devices monitor metrics such as heart rate, temperature, time, and distance. Like pulse oximeters, they are often composed of two units: a sensor and a receiver or display unit (see figure).

The sensing portion is a chest strap with heart-rate and temperature sensors. It conditions the cardiac signal before conversion, then wirelessly transmits the data to a receiver. The receiver may be a watch that displays information or forwards it to a PC or cloud service for logging and analysis. Some fitness classes even display group statistics on large screens for motivation and monitoring.

Common wearable architecture

Comparing the architectures of these medical and wearable devices shows many common elements:

- One or more dedicated sensors measure bio-signals. The parameters of interest are typically analog by nature, and many devices measure multiple signals.

- An analog front end (AFE) captures and conditions sensor signals. The AFE often includes front-end signal conditioning circuits such as operational amplifiers, transimpedance amplifiers, or programmable gain amplifiers (PGA); the front-end output feeds a precision analog-to-digital converter (ADC).

- A low-power microcontroller controls and coordinates other components. Low-power modes keep the MCU asleep most of the time and wake it periodically for measurements or in response to incoming data, extending battery life. The microcontroller also implements security functions to prevent unauthorized access to patient or user data.

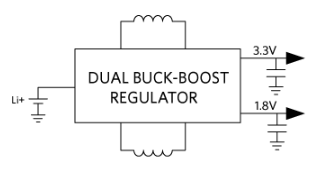

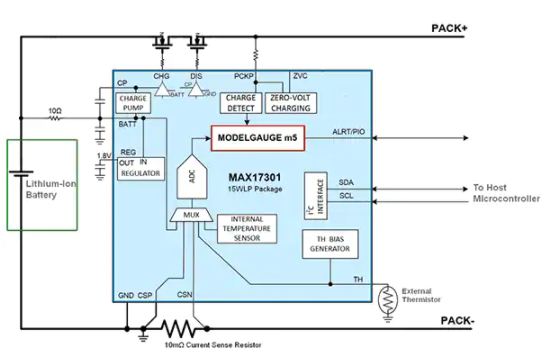

- A power module consists of regulators, voltage references, protection circuits, the battery, and battery-management circuitry. Voltage regulation may include linear and switching topologies. Rechargeable batteries require wired or wireless chargers.

- Wired or wireless data ports exchange information with other devices. Common interfaces include USB, Wi-Fi (IEEE 802.11), and Bluetooth Low Energy (BLE).

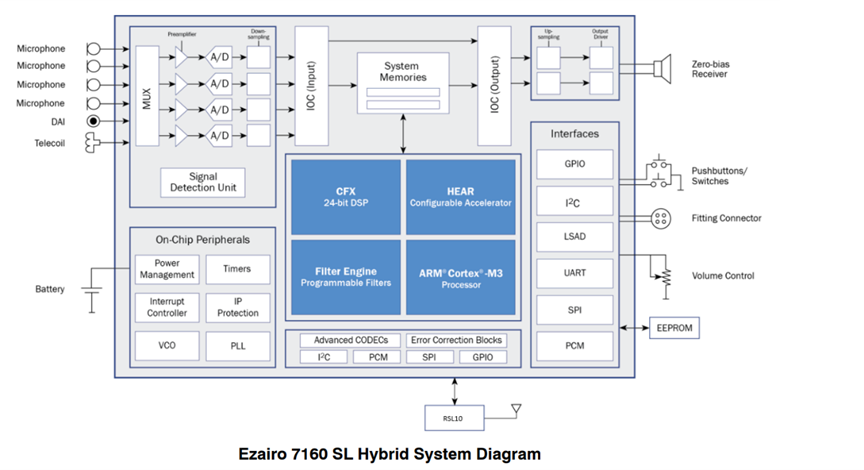

- A human-machine interface (HMI) displays results and accepts user input. The HMI commonly includes displays, buttons, speakers, possibly a microphone, and interface components such as display drivers, DC converters, and digital-to-analog converters (DACs).

Similarities extend beyond hardware into software. Data security is critical for both health and fitness applications. Encryption and authentication are key components in most designs. If a product targets clinical environments, regulations such as HIPAA may impose security requirements. Other common software elements include BLE or USB stacks, display drivers, and user interface routines.

Ready-made development platforms shorten time to market

Designing wearable health or fitness products can be complex, and designers often face severe time-to-market pressure. Because many portable health and fitness products share similar requirements, component vendors provide turnkey development platforms to reduce development time. These platforms can serve as the basis for multiple health and fitness applications.

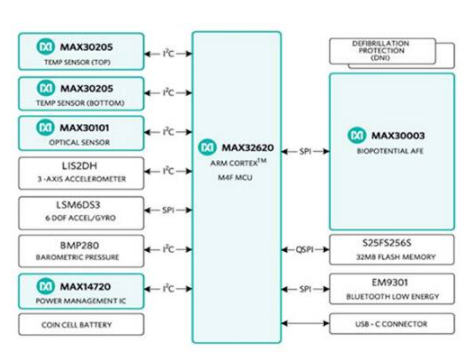

For example, Maxim Integrated's MAXREFDES100# hSensor platform integrates hardware building blocks on a single PCB and provides easy access to hardware features through an ARM mbed hardware development kit (HDK).

The hSensor platform includes an hSensor board, firmware with drivers, a graphical user interface (GUI), and a debugger board.

Firmware source code is available from Maxim Integrated, allowing engineers to load algorithms to adapt the platform to different use cases. Designers can download firmware to optimize designs, speed evaluations, and significantly shorten time to market. Schematics, bill of materials (BOM), layout files, Gerber files, and software are also available online.

Components on the hSensor platform are optimized for portable and wearable applications to reduce overall power consumption. The board measures 25.4 mm x 30.5 mm, small enough to fit clinical or fitness applications worn on the chest, arm, wrist, finger, or ear.

Sensors and AFE circuits

The platform includes sensors for common health and fitness functions. It can measure skin temperature and heart rate and supports biopotential measurements such as ECG, electromyography (EMG), and electroencephalography (EEG). For fitness band applications, an accelerometer/gyroscope combination senses motion and rotation; the platform also includes a barometric pressure sensor.

Several dedicated devices support biological functions. For example, the MAX30101 optical sensor integrates optical and electrical functions and can serve as a high-sensitivity pulse oximeter and heart-rate sensor.

The MAX30101 combines red, green, and IR LEDs, a photodiode, and AFE circuitry such as an 18-bit delta-sigma ADC, along with ambient light cancellation. Communication is provided via an industry-standard I2C interface. A proximity feature reduces power when a finger is not near the sensor.

The MAX30205 clinical temperature sensor provides 0.1°C accuracy and 16-bit resolution. It is optimized for low-voltage (2.7 V to 3.3 V) and low-current (600 μA) wearable operation. The part includes an overtemperature alert and communicates over I2C. When soldered to production PCBs, its accuracy meets clinical thermometry specifications such as ASTM E1112.

The MAX30003 single-channel integrated biopotential AFE interfaces to ECG applications. Its signal chain includes an input multiplexer and an instrumentation amplifier followed by a low-pass filter with selectable cutoff and a PGA.

Like other hSensor devices, this part helps extend battery life, consuming only 85 μW at 1.1 V operating voltage. It also supports deep-sleep modes until it detects a valid ECG lead. Configurable interrupts can wake the microcontroller only on each heartbeat to further reduce power consumption.

Microcontroller

The controller is an ultra-low-power 32-bit ARM Cortex-M4F core with a floating-point unit. As with other hSensor components, the MCU is optimized for wearables with four flexible power modes and firmware-controllable power gating to minimize consumption. The device includes a four-input, 10-bit ADC with an optional voltage reference, serial interfaces including SPI, UART, and I2C, an integrated USB 2.0 transceiver, and a 1-Wire master module.

Power section

The MAX14720 is at the core of the power-management module. The device is designed for space-constrained battery-powered applications and integrates power switches, a linear regulator, a buck regulator, and a buck-boost regulator. An external button controls MAX14720 power sequencing: a three-second press turns the PMIC on and it shuts off after 20 seconds.

Data communications

The hSensor platform includes wired and wireless communication ports. The MCU provides USB 2.0 via a reversible USB Type-C connector to minimize PCB area. Wireless BLE communication is provided by a fully integrated single-chip controller from EM Microelectronics, enabling the hSensor platform to act as either a BLE central or peripheral.

Software support

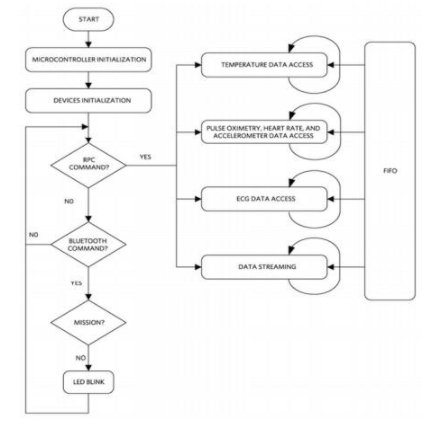

Software support includes PC and Android applications. A PC application provides a GUI that uses USB to configure the system and read sensor data. An Android application provides BLE functionality.

Developers can customize platform behavior using the ARM mbed development environment. The reference design includes the MAXREFDES100HDK# programming adapter, which provides driver-free drag-and-drop programming for firmware updates, a virtual UART interface, and a debugger compatible with ARM's CMSIS-DAP interface firmware.

The firmware implements an interrupt-driven model. On power-up, the microcontroller configures the power-management devices and sensors to default settings, then waits for remote procedure calls (RPCs) from the GUI or Android application.

Conclusion

Wearable products for health or fitness markets must meet strict performance requirements, consume minimal power, and fit into very small enclosures. Designs must combine dedicated sensors, precision analog circuits, digital control, and wired or wireless communication.

For health sensing applications, working hardware and firmware platforms let designers rapidly validate concepts or use existing platform features as the basis for new designs.

Maxim Integrated's MAXREFDES100# reference design provides such a platform. It is optimized for these applications and includes designed-and-tested modules that simplify development and shorten time to market. The platform includes an hSensor board with multiple health-related sensors, an industry-standard ARM-core microcontroller, and a downloadable source-code software ecosystem.

Using these components, designers can quickly configure a baseline design, focus on product differentiation, and significantly reduce product development time. In the fast-paced wearable health and fitness market, that reduction in development time can be the difference between product success and failure.

ALLPCB

ALLPCB