For electronics manufacturers, selecting the right automated rework system is crucial to ensure precision, efficiency, and reliability in repairing or modifying printed circuit boards (PCBs). Whether you're dealing with Ball Grid Array (BGA) components or Surface Mount Technology (SMT) parts, the right equipment can save time, reduce costs, and improve product quality. In this guide, we'll explore key rework system selection criteria, provide an automated rework station comparison, offer a BGA rework system buying guide, and highlight essential factors for choosing SMT component rework equipment.

This blog post will dive deep into the factors that matter most when investing in an automated rework system. From understanding the types of components you work with to evaluating system features and budget considerations, we've got you covered with actionable insights to make an informed decision.

Why Automated Rework Systems Matter in Electronics Manufacturing

In the fast-paced world of electronics manufacturing, mistakes or defects on PCBs can lead to costly delays or product failures. Automated rework systems are specialized tools designed to remove, replace, or repair components like BGAs, Chip Scale Packages (CSPs), and other SMT parts without damaging the board or surrounding elements. These systems are vital for maintaining high-quality standards, especially as components become smaller and more complex, with pin counts often exceeding 1000 and pitches as tight as 0.3mm.

Using an automated system over manual methods offers several advantages, including higher precision, repeatability, and reduced risk of human error. For manufacturers handling high-volume production or intricate designs, investing in the right equipment can significantly boost efficiency and ensure consistent results.

Key Rework System Selection Criteria for Manufacturers

When choosing an automated rework system, it's important to focus on specific criteria that align with your manufacturing needs. Below are the essential factors to consider:

1. Component Compatibility

The first step in selecting a rework system is ensuring it can handle the types of components you work with. For instance, if your production involves BGAs with hundreds of pins or ultra-fine pitch components, you'll need a system with advanced optical alignment and precise temperature control. Similarly, SMT components vary in size and sensitivity, so check if the equipment supports a wide range of part dimensions, from micro-SMDs to larger QFPs.

Look for systems that offer flexibility to handle both current and future component types, as technology evolves rapidly in electronics manufacturing.

2. Precision and Control

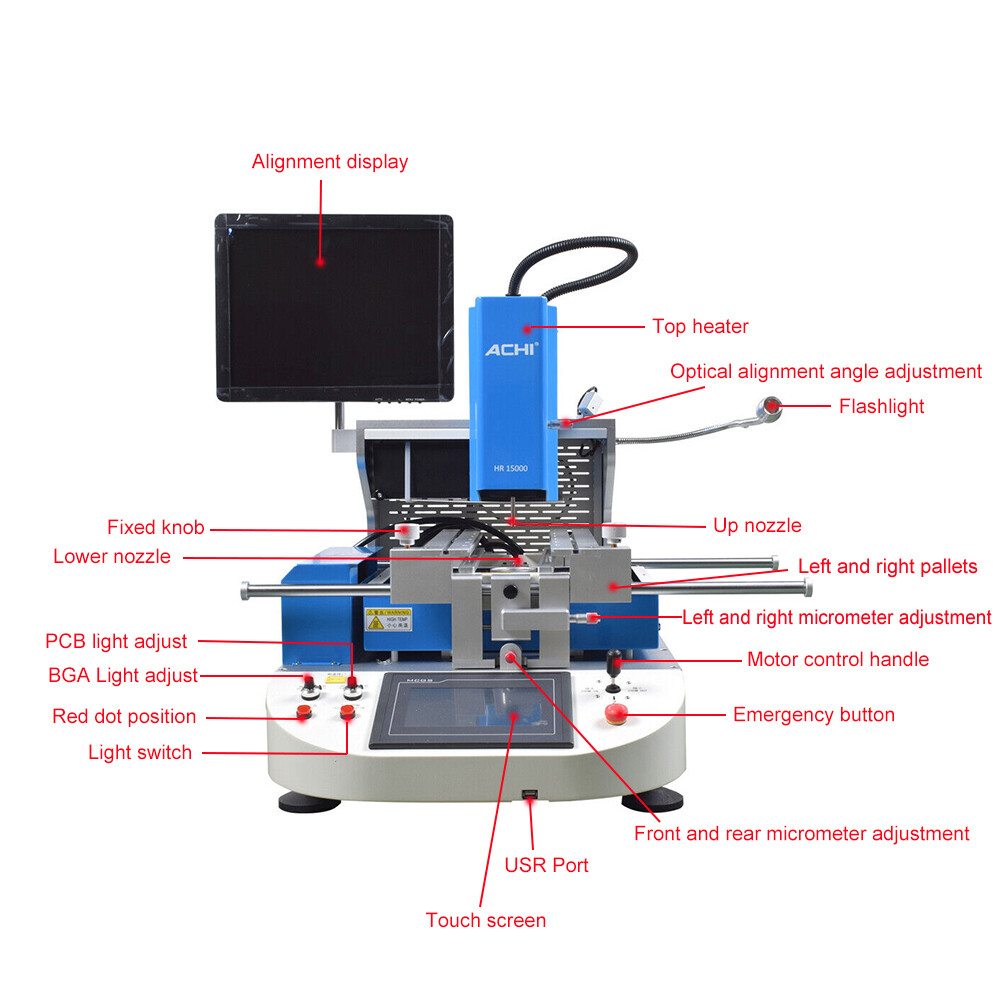

Precision is non-negotiable when dealing with delicate PCB assemblies. Automated rework stations with features like closed-loop temperature control and high-resolution cameras for alignment can ensure accurate placement and soldering. For example, temperature accuracy within ±2°C is often necessary to prevent overheating sensitive components, while alignment systems with micrometer-level precision (e.g., 10μm) are ideal for dense boards.

Evaluate the level of automation offered—fully automated systems can handle complex tasks with minimal operator input, reducing errors and improving consistency.

3. Ease of Use and Training Requirements

While advanced features are important, the system should also be user-friendly. Complex equipment with steep learning curves can lead to downtime and inefficiencies. Look for rework stations with intuitive software interfaces and programmable profiles that allow operators to quickly set up processes for different components.

Additionally, consider the availability of training and technical support to ensure your team can operate the system effectively from day one.

4. Throughput and Efficiency

For high-volume manufacturers, the speed and throughput of a rework system are critical. Some automated stations can process multiple boards simultaneously or complete a BGA rework cycle in under 10 minutes. Check specifications like heating and cooling times, as well as the ability to handle batch operations, to ensure the system matches your production demands.

5. Budget and Cost of Ownership

Automated rework systems come in a wide range of prices, from entry-level models starting at $5,000 to high-end solutions exceeding $50,000. While upfront cost is a factor, also consider the long-term cost of ownership, including maintenance, consumables like nozzles and soldering tips, and energy consumption.

Investing in a slightly more expensive system with better durability and lower maintenance needs can often save money over time compared to cheaper models that require frequent repairs.

Automated Rework Station Comparison: Types and Features

Not all automated rework stations are created equal. Understanding the different types and their features can help you narrow down your options. Here's a breakdown of common categories and what to look for:

1. Infrared (IR) Rework Stations

IR rework stations use infrared heating to reflow solder and remove or place components. They are often more affordable and suitable for smaller components or less complex boards. However, they may lack the precision needed for densely populated PCBs or large BGAs, as heat distribution can be uneven.

Best for: Small to medium-sized manufacturers with simpler rework needs.

2. Hot Air Rework Stations

Hot air systems use focused streams of heated air to melt solder, offering better control over temperature and heat distribution compared to IR models. They are versatile and can handle a wide range of components, including BGAs and SMT parts, with typical airflow rates ranging from 20 to 120 liters per minute for optimal performance.

Best for: Medium to large manufacturers needing flexibility for various component types.

3. Hybrid Rework Systems

Hybrid systems combine IR and hot air technologies or integrate additional features like laser heating for pinpoint accuracy. These are ideal for complex, high-density boards and offer advanced automation features, such as auto-alignment and solder residue removal. They tend to be more expensive but provide unmatched precision and efficiency.

Best for: High-end manufacturing with intricate designs and strict quality requirements.

Key Features to Compare:

- Temperature Range: Look for systems with adjustable ranges (e.g., 100°C to 450°C) to accommodate different soldering profiles.

- Alignment Technology: Optical alignment systems with high-resolution cameras (at least 1080p) ensure accurate component placement.

- Software Capabilities: Advanced software for process monitoring and data logging can improve traceability and quality control.

- Footprint: Ensure the system fits your workspace, as some high-end models can be bulky.

BGA Rework System Buying Guide: What to Prioritize

BGA components are among the most challenging to rework due to their high pin density and hidden connections. When selecting a BGA rework system, focus on the following aspects to ensure successful repairs:

1. Optical Alignment and Vision Systems

Accurate placement is critical for BGA rework. Systems with split-vision cameras or automated optical alignment can overlay the component and PCB pads for precise positioning, reducing the risk of misalignment. Look for systems offering real-time imaging with zoom capabilities up to 50x magnification.

2. Temperature Profiling

BGAs require precise thermal profiles to avoid damaging the component or board. Choose a system that allows customizable heating and cooling curves, with ramp rates as low as 0.5°C per second for delicate components. Closed-loop control ensures the actual temperature matches the set profile within a tight tolerance.

3. Reballing and Soldering Capabilities

Reballing—reapplying solder balls to a BGA component—is often necessary during rework. Ensure the system supports reballing kits and offers uniform heat distribution for consistent results. Additionally, check for compatibility with lead-free solder, which requires higher temperatures (up to 260°C) compared to traditional solder.

4. Board Size and Component Range

Confirm that the system can accommodate the PCB sizes you work with, whether they’re small mobile device boards or larger server panels (e.g., up to 500mm x 500mm). It should also handle a variety of BGA sizes, from micro-BGAs (under 5mm) to larger packages exceeding 50mm.

SMT Component Rework Equipment: Essential Considerations

SMT component rework equipment is designed to handle a broader range of surface-mounted parts beyond just BGAs. Here’s what to keep in mind when selecting equipment for SMT rework:

1. Versatility for Different Components

SMT components include resistors, capacitors, QFPs, and more, each with unique rework challenges. Opt for equipment with interchangeable nozzles and tools to handle various shapes and sizes. For instance, fine-pitch QFPs may require specialized tips with 0.2mm precision for accurate soldering.

2. Non-Destructive Removal

Removing SMT components without damaging the board or nearby parts is essential. Look for systems with controlled heat and vacuum tools for safe desoldering. Some advanced models offer automatic solder residue removal to streamline the process.

3. Integration with Production Lines

If your manufacturing setup includes automated assembly lines, consider rework equipment that integrates seamlessly with existing systems. Compatibility with industry-standard protocols and software can reduce setup time and improve workflow efficiency.

How to Evaluate Vendors and Make a Final Decision

Once you’ve narrowed down your options based on technical specifications, it’s time to evaluate potential vendors. Here are some tips to guide your final decision:

- Reputation and Reviews: Research vendor reliability and customer feedback to ensure they provide quality equipment and support.

- After-Sales Support: Confirm the availability of spare parts, software updates, and technical assistance to minimize downtime.

- Demonstrations and Trials: If possible, request a demo or trial period to test the system with your specific components and PCBs.

- Warranty and Service Contracts: A solid warranty (at least 1-2 years) and optional service contracts can provide peace of mind.

Conclusion: Making an Informed Investment in Automated Rework Systems

Choosing the right automated rework system is a strategic decision that can impact the quality, efficiency, and profitability of your electronics manufacturing process. By focusing on rework system selection criteria like component compatibility, precision, and cost of ownership, and by comparing features across different automated rework stations, you can find the perfect fit for your needs. Whether you're looking for a BGA rework system or versatile SMT component rework equipment, this guide provides the foundation to make an informed choice.

Investing in the right equipment today ensures you’re prepared for the challenges of tomorrow’s increasingly complex PCB designs. Take the time to evaluate your options, prioritize your specific requirements, and partner with a reliable vendor to achieve long-term success in electronics manufacturing.

ALLPCB

ALLPCB