In the world of PCB assembly, finding ways to boost efficiency and cut costs without sacrificing quality is a top priority for engineers and manufacturers. One technique that has proven to be a game-changer is the use of "mouse bites" in PCB panelization. But how exactly do mouse bites improve PCB assembly? In this case study, we’ll dive into the specifics of how this simple design feature enhances efficiency, reduces costs, and streamlines production processes. Through real-world examples and detailed explanations, you’ll learn why mouse bites are becoming a go-to solution for many in the industry.

What Are Mouse Bites in PCB Assembly?

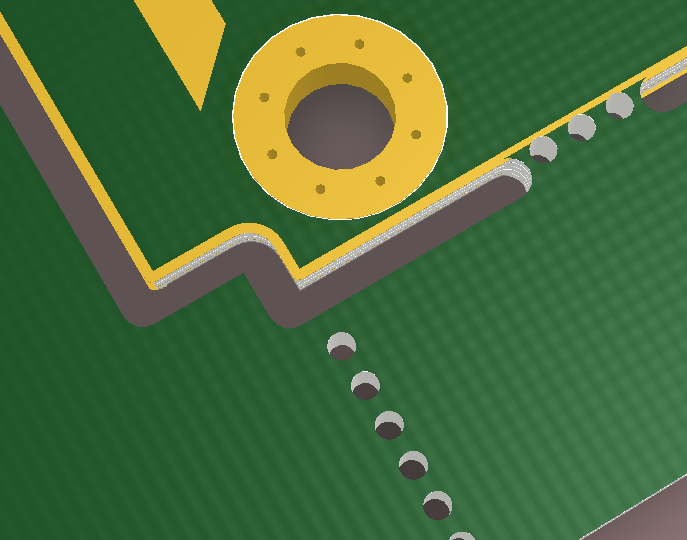

Mouse bites are small, perforated holes or notches placed along the edges of individual PCBs within a larger panel. These perforations act as breakaway points, allowing manufacturers to easily separate each board from the panel after assembly. Think of them as the tiny holes you see on a sheet of stamps—easy to tear apart without needing special tools. In PCB manufacturing, mouse bites serve a similar purpose, making the depaneling process smoother and more cost-effective.

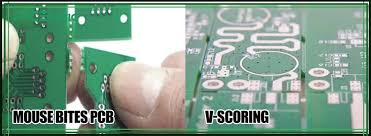

Unlike other methods like V-scoring (which involves cutting a groove into the panel), mouse bites create a series of small holes that weaken the connection just enough for manual separation. This design is particularly useful for small to medium production runs or prototypes where simplicity and affordability are key.

Why Mouse Bites Matter for Efficiency Improvements

In PCB assembly, time is money. Every step in the manufacturing process needs to be optimized to keep production moving smoothly. Mouse bites play a critical role in improving efficiency, especially during the depaneling stage. Here’s how:

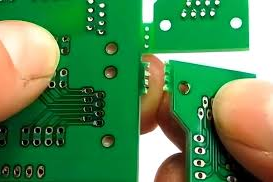

- Simplified Depaneling: With mouse bites, separating individual boards from a panel is quick and doesn’t require expensive machinery. Workers can often break the boards apart by hand or with minimal tools, shaving minutes off the process for each panel.

- Reduced Risk of Damage: Unlike other methods that might involve cutting or heavy force, mouse bites minimize the chance of damaging delicate components near the board’s edges. This leads to fewer rejected units and less rework.

- Better Panel Utilization: Mouse bites allow for tighter spacing between boards on a panel since there’s no need for wide grooves or extra clearance for cutting tools. This means more boards can fit into a single panel, maximizing material usage.

For instance, in a production run of 500 small PCBs, using mouse bites could reduce depaneling time by up to 30% compared to manual cutting methods. This kind of efficiency adds up quickly in large-scale operations.

Cost Savings with Mouse Bites: A Real-World Example

One of the standout benefits of mouse bites in PCB assembly is the significant cost savings they offer. Let’s break this down with a practical case study from a mid-sized electronics manufacturer specializing in IoT devices.

Case Study Background: The company was producing 10,000 units of a compact sensor board each month. Initially, they relied on V-scoring for panelization, which required specialized equipment for separation. The process was not only time-consuming but also resulted in a 5% damage rate to boards during depaneling due to stress on components near the edges. Additionally, the cost of maintaining and operating the depaneling equipment added $2,000 to their monthly expenses.

Implementing Mouse Bites: After consulting with their PCB fabrication partner, the company switched to a panel design incorporating mouse bites. The perforations were strategically placed to avoid critical components, and the boards could be separated by hand in most cases. Here’s what changed:

- Equipment Costs Eliminated: Since mouse bites allowed for manual separation, the need for specialized depaneling tools was removed, saving $2,000 per month.

- Lower Damage Rates: The gentler separation process reduced board damage to less than 1%, saving an estimated $1,500 monthly in rework and replacements.

- Faster Production: Depaneling time dropped by 40%, enabling the team to handle larger batches in less time, indirectly reducing labor costs by $800 per month.

In total, the switch to mouse bites saved the company over $4,300 monthly while improving overall product quality. These numbers highlight how a small design change can lead to substantial financial benefits.

How Mouse Bites Enhance SMT Assembly Processes

Surface Mount Technology (SMT) assembly, where components are placed directly onto the surface of a PCB, is a cornerstone of modern electronics manufacturing. Mouse bites are particularly advantageous in SMT workflows because they improve panel stability and alignment during assembly.

During SMT assembly, panels go through automated pick-and-place machines that require precise positioning. Mouse bites provide just enough connection between boards to keep the panel rigid, preventing misalignment or shifting during the process. Once assembly is complete, the boards can still be separated easily without stressing the soldered components.

For example, in a high-volume production of LED driver boards, a manufacturer reported a 15% improvement in SMT placement accuracy after switching to mouse bite panelization. The stronger panel structure reduced vibrations during machine operation, leading to fewer placement errors and a smoother assembly line.

Design Considerations for Implementing Mouse Bites

While mouse bites offer clear benefits for PCB assembly efficiency and cost savings, proper design is crucial to maximize their effectiveness. Here are some key factors to keep in mind when incorporating mouse bites into your PCB layout:

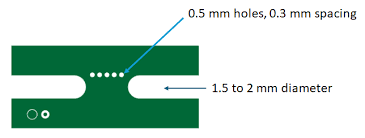

- Hole Size and Spacing: The perforations should be small enough to hold the panel together during assembly but large enough to allow easy separation. A common configuration is 0.5mm diameter holes spaced 1mm apart, though this can vary based on board thickness and material.

- Edge Clearance: Ensure that mouse bites are placed away from sensitive components or traces to avoid damage during separation. A minimum clearance of 2mm from critical areas is often recommended.

- Panel Strength: For larger or heavier boards, consider adding more connection points or using a combination of mouse bites and breakaway tabs to maintain panel integrity during handling.

By carefully planning the placement and configuration of mouse bites, manufacturers can avoid common pitfalls like premature board separation or excessive stress on the panel.

Mouse Bites vs. Other Depaneling Methods

To fully appreciate the value of mouse bites, it’s helpful to compare them with other common depaneling techniques like V-scoring and breakaway tabs. Each method has its strengths, but mouse bites often stand out for their balance of cost and simplicity.

- Mouse Bites: Best for small to medium runs and prototypes. They’re inexpensive, easy to implement, and require no special tools for separation. However, they may leave rough edges that need sanding in some applications.

- V-Scoring: Ideal for high-volume production where precision is critical. V-scoring creates clean edges but requires specialized cutting equipment, adding to costs. It can also stress components if not done carefully.

- Breakaway Tabs: Similar to mouse bites, breakaway tabs are small connection points that can be snapped off. They’re slightly stronger than mouse bites but may require more force to separate, increasing the risk of damage.

For many manufacturers focused on cost savings and efficiency improvements, mouse bites strike the perfect balance. They offer a low-cost solution without the complexity or expense of other methods, making them a popular choice for a wide range of projects.

Challenges and Limitations of Mouse Bites

While mouse bites are highly effective in many scenarios, they’re not without challenges. Understanding these limitations can help engineers decide when and how to use them in PCB assembly.

- Rough Edges: After separation, the edges where mouse bites were located may be uneven or jagged. This isn’t usually a functional issue but can be a concern for aesthetic reasons or if the board will be handled frequently.

- Not Suitable for All Designs: For very thin or flexible PCBs, mouse bites may cause unintended tearing or deformation. In such cases, alternative methods like V-scoring might be better.

- Manual Effort: Although mouse bites reduce the need for tools, separating larger panels or tougher materials may still require significant manual effort, which can slow down production in high-volume settings.

Despite these drawbacks, the benefits of mouse bites often outweigh the challenges, especially for projects where budget and speed are top priorities.

Conclusion: Why Mouse Bites Are a Smart Choice for PCB Assembly

In the quest for efficiency improvements and cost savings in PCB assembly, mouse bites have emerged as a simple yet powerful solution. As demonstrated in the case study, this panelization technique can save thousands of dollars monthly by reducing equipment costs, minimizing damage, and speeding up production. Whether you’re working on a prototype or a large-scale run, mouse bites offer a practical way to streamline the depaneling process without compromising quality.

By incorporating mouse bites into your PCB design, you can take advantage of faster assembly, lower expenses, and improved panel utilization. For engineers and manufacturers looking to optimize their workflows, this small design feature can make a big difference. If you’re ready to explore how mouse bites can enhance your next project, consider partnering with a trusted PCB fabrication service to ensure the best results.

ALLPCB

ALLPCB